Well, it happened: Your nightmare has come to life. Your grow is on the brink of drying out. Or you walked in and your curing room is at 100% humidity and 100 degrees Fahrenheit. Or a vent wasn’t properly closed and your greenhouse now is riddled with spider mites. What do you do now? At what point do you just start over? What steps can you take to make sure this never happens again?

In every grow, just like any other business, not only do you need to think about worst-case scenarios, but you also need to have systems in place to minimize the damage to the crop due to those risks. Having a good plan in place and having a system with redundancies to be able to help you in those cases can be the difference between you going out of business or taking a large loss. These plans can also help you avoid any major damage at all.

Having at least one manual backup system for every automated environmental control is crucial.

Here are some of the worst unexpected disasters that can happen to a cannabis cultivator during the height of growing season, what you can do to plan and prepare for that situation, and how you can best navigate it.

Provide Worst-Case Scenario Training

When setting up your facility to prevent disasters from happening, it may sound backward, but try to plan for the unplannable. You can draft plans all you like, but having a team in place that can handle stressful situations is usually the best mitigator of loss. What happens the first few minutes to an hour when you first notice something going wrong can dictate how severe the damage can or will get. Having someone who can quickly assess the situation and then coordinate with the available employees to enact your plan is critical to pulling off a successful save. The cultivation or site manager should not only have a great understanding of the building, systems, employees, and plans, but also all their individual strengths and weaknesses and how to use every single one of those resources to their advantage.

Occasional stress tests can help shape a team and prepare them, but the best thing you can typically do is review your backup plans with employees every time you hire someone. Empowering your employees and having them know the resources available to them at all times and how to best use them can often lead to problems being solved before they can have a larger effect. Of course, having a great team and proper training is only part of the puzzle.

Plan For Power Outages

At Heartland Industries in Colorado, we grow in a greenhouse, and one of our biggest challenges is when snowstorms knock out power or inhibit employees from being able to access the facility. During winter, we use a backup generator to power the boiler unit that keeps the floor warm and the pump for the fertigation system that feeds the plants. It is best to have a dual power source generator in case of emergencies. For example, during the winter storm in Texas this past year, natural gas lines froze. If they could have used gasoline or diesel, then they would have been able to keep everything running without any crop loss.

While our greenhouse is automated, our backup systems are not, meaning someone needs to be able to make it to the greenhouse no matter the conditions outside. We have an employee who can make it to the facility even with road closures. In extreme storms, we have had employees spend the night sleeping in the office with an air mattress and sleeping bag. Having an employee who is willing to do that may be critical to keeping your operations running, and they need to be able to operate the backup systems if need be.

We’ve also had our cooling system go down in the middle of summer, most commonly from loss of power, whether it be storms, wind, or even the rare car crash into a utility pole. In those instances, we designed our greenhouse with roof vents that we can manually open in emergency situations to release the heat. This extra system, while carrying a large upfront cost (these systems can be priced from thousands to hundreds of thousands depending on the size of your greenhouse), can pay for itself the first time you use it to save your crop. This is something that will have to be done in the original design and cannot be retrofitted, so be sure to keep that in mind during the design. Having at least one manual backup system for every automated environmental control is crucial.

Secure Back-Up Water Sources and Systems

Whether your water supply is stopped completely or your automated watering system goes down, having a backup in place will limit the number of plants you lose.

Establish a relationship with a water hauling company or a secondary source of water. We built that relationship through paying a premium when we do need water and by always paying our bills on time. At Heartland Industries, we have had to fill our water reservoirs with water hauled in on a tanker. Being able to call up a water supplier that made our company a priority has saved our plants on more than one occasion.

If having water hauled in is not an option, investigate other water sourcing options. Even if you are on city water or have your own well and do maintenance regularly, unexpected things can happen, like the water company having to switch the supply, a contaminant that shuts down the lines, or a pipe failure. Quickly getting a new water source then will be the main priority.

Other water-related disasters include automated watering system catastrophes. It could be a full zone of drippers clogging, a main line breaking, a pump going down, a nutrient dosing unit shutting off, or a blocked filter stopping your flow. Regardless of the issue, a backup system is a necessity. Watering systems, even when new, can fail for many reasons, and crop damage or loss can happen while you’re trying to diagnose and fix the issue. The minimum backup system required is a source of (clean) water, a pump, a hose and a wand. Although you will lose a great deal of labor time by switching to hand-watering, your crop will stay hydrated. Having a complete backup automated system is ideal, but as long as there’s a way to move water to plants and SOPs in place for employees to irrigate them, you and your team will be able to save them.

In addition, having a backup nutrient delivery system will not only allow you to save the crop from drying out, but possibly from any loss at all from the plant being stressed. Stress in the plant can cause crop loss in many ways, including by attracting pests that will smell the stress hormones and attack; the plant using all of its stored water and nutrients in its leaves leading to deficiencies; or even by causing a root disease because the root zone lost all of its mycorrhizae. The easiest way to ensure nutrients are available is to have a reservoir that can be filled and moved to where your pump and hose can be used effectively. By being able to put the smaller portable tank where you need, you then can mix in the nutrients and begin to water the plants that need it most first. Getting water and the proper nutrients to the plants is key to keeping plant health as close to normal as possible.

Pest & Mold Outbreak

The other main stressors that can quickly manifest and threaten your plants are pests and mold. Pests and mold come in silently, and if you are not already taking preventive measures to limit the amount of risk your plants have, you could have a significant infestation on your hands within a couple of days. The first step to avoiding this problem altogether is to have a great scouting and integrated pest management (IPM) system. That said, sometimes even the best systems fail.

Each state has a different set of laws and regulations limiting what you can do, so when researching what products you can use, be sure to not only plan your preventive system, but also a curative plan at the same time. That could mean having a different dosing amount based on what the label states or using a different technique altogether.

Once russet mites are found in your grow, immediately quarantine those contaminated plants away from the production area as quickly and safely as possible.

As an example, in Colorado we are allowed to use certain pesticides in plant production but once we get close to harvest, it’s best not to spray the crop. Spraying the crop can affect not only flower yield, but also the trim. (Also, consumers really don’t want to be smoking pesticides on your flower.)

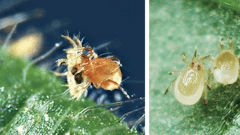

If spider mites decide that they want to move in, you may need to deal with them to sell your crop at normal market price. In that case, you would want to do some research into predatory mites based on your climate and time of year. These beneficial insects will fight the spider mite population without causing any adverse effects to the cannabis crop.

The other major issue that tends to be problematic in cannabis cultivation is russet mites. Russet mites and a few other pests like mealybugs can wipe out entire crops if you do not act fast enough, and they are quite honestly the most difficult battle I have ever had to fight with plants. If there’s a full-blown outbreak, the only option will be to clean the entire facility and get rid of the plants until it is safe for them to be in there again. This is obviously the worst-case scenario, but it may be necessary to get rid of the pest.

Once russet mites are found in your grow, immediately quarantine those contaminated plants away from the production area as quickly and safely as possible. Limiting the spread and controlling the pest population is crucial. Place a bag over the entire plant, cut it down from the stalk and tie the bag. (If necessary, you may need to cut the plant into pieces to get it to fit into the bag.) Then, bag up the soil and dispose of it properly as far from the other plants as possible.

Immediately treat all plants in the area with the strongest miticide you have available or spot treat with predatory mites. Consider increasing your IPM practices from preventive up to a curative level for a couple of weeks, if possible.

Once the russet or broad mites have established a colony and become prevalent, a new chemical may need to be introduced (depending on state regulations) or you may need to increase your beneficial insect orders for a few weeks. Be sure to always stay up to date on state regulations for what you can and cannot use in cannabis production.

At the end of the day, any catastrophe can be managed if you have the right team, training, plans, and equipment to take care of it. The hope is that these tips can help you avoid the worst.