As we close out 2019, I’ve compiled a list of common cultivation challenges that growers must address to achieve ongoing success. From breeding to business planning, here are some key tips cultivators should consider to reduce risk and maximize profits in their operations.

Infection Prevention 101

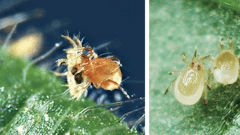

Everyone knows, has read or has been told many times over to quarantine clones before introducing them into a pest- and disease-free environment. But I still hear about very large-scale facilities being infected with broad or russet mites due to the introduction of infected clones. Some growers and facility employees also don’t completely decontaminate themselves or change attire after working in a quarantine environment.

TIP 1: The best solution to avoid infecting your facility when introducing new genetics is to use tissue culture for all specimens you introduce to a clean environment. Tissue culture, or meristem culture, is the only way to guarantee you are starting with clean stock.

TIP 2: The next best option is to have an off-site quarantine environment, which allows for compartmentalization so that new specimens are separate from others. Some quarantine those genetics at the same location at which they grow or in close proximity, but that is risky, as they should never be in close proximity unless they are deemed completely pest and disease free.

TIP 3: Lab test any specimens that are pest and disease free for powdery mildew and record them microscopically. Review the video on a large screen so you can more easily detect pests as well as their larvae, eggs or feces. This is a critical step because broad mites or russet mites can be devastating to an operation.

TIP 4: The only sure treatment once an outbreak is confirmed is to destroy all plants, disinfect the entire facility and start from scratch—hopefully after successfully preserving the genetic library via tissue cultured specimens.

Considering that infected cannabis is worthless, it makes perfect sense for a grower to do everything possible to be and stay pest and disease free. Besides the obvious of not introducing infected genetics in the form of infested clones and personal decontamination and changing attire, a few other prevention points exist.

TIP 5: The first entry point of infection is typically from the fresh air intake. Greenhouse growers must incorporate and use bug screens as a pre-filter, then at the very least sterilize the air by utilizing UV air sterilizers.

TIP 6: In addition to UV air sterilizers, both greenhouse growers and indoor growers should use HEPA filters on all incoming air whenever possible. Filtering and sterilizing all recycled air can help prevent mold and mildew from proliferating in cultivation areas.

Sustainable Solutions

Sustainable production can help growers reduce costly waste and differentiate themselves in a crowded marketplace. Wastewater recycling is one of several sustainable practices growers should consider in their operations. Unfortunately, some growers may take shortcuts and reuse untreated water because they’re limited on what equipment they can use due to space or financial constraints. But reusing unsterilized water is a recipe for disaster; it can throw off your pH and nutrient levels or spread disease throughout your crop, as it only takes one plant to infect the water supply.

TIP 7: Growers should always properly filter and sterilize their water prior to re-application. They should filter recycled water through reverse osmosis before using it. Then, sterilize the water using UV sterilizers or ozone.

TIP 8: If sustainability is a priority for you, whenever possible, use recycled materials in packaging and irrigation lines. In a perfect world, all cannabis refuse would be manufactured into packaging for cannabis products. For instance, growers can make plastic from cellulose derived from the extraction waste and can use the pulp from stocks and stems as well as from biomass and extraction waste for packaging.

As demand increases for recycled packaging, we will likely see an increase in the availability of recycled materials across the supply chain.

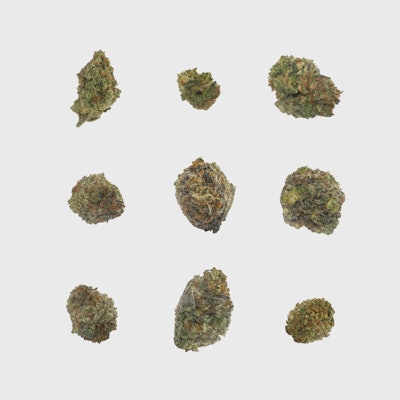

Drying and Curing Best Practices

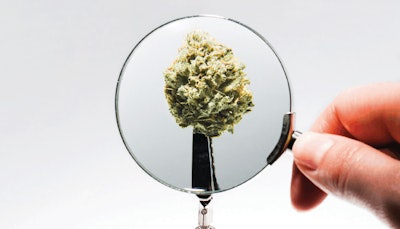

Bud density is a major factor in the drying and curing stage. Small buds dry faster than large ones, meaning if you wait for the large buds to completely dry, the small and medium buds will be overdried. Overdried buds have fewer terpenes available, as they evaporate along with the water during the drying process, making the buds less flavorful and aromatic than they could potentially have been, resulting in a lackluster consumer experience.

TIP 9: Sort through large, medium and small buds to gain better control of the drying rate of each. Also, if cultivators separate and dry by bud size and then recombine each batch as it dries over the curing stage, the final result is typically a more homogeneous and uniformly dried product that has maximum terpene preservation (if all other conditions are met).

TIP 10: Make sure the buds are properly stored, as THC degrades rapidly when exposed to oxygen, light and heat, the primary enemies of THC. Even when properly stored, cannabis has a six-month shelf life, after which THC begins to convert to CBN. Not to say this cannabis is necessarily bad, but it has passed its peak THC and terpene content.

Growers who are stocking cannabis for longer than six months should store it in subzero temperatures in oxygen-free containers (where the oxygen is displaced by gaseous C02 or nitrogen).

THC in concentrates also rapidly degrades and converts to CBN. This, in turn, applies to all products manufactured from a distillate, including all edibles. While a gummy is on a shelf, the THC within is in a constant state of degradation/conversion.

Also, work with retailers to avoid displaying products in sunlight, and talk with packaging companies about how their products help with product quality maintenance.

Business Planning for a Changing World

The U.S. trade war with China has led both countries to impose tariffs. This has increased the cost of goods from China (and other tariffed countries), including vape pen cartridges. In addition, local governments continue to impose new regulations that make production and sales more challenging.

TIP 11: Many times, there is simply no alternative. But whenever possible, cultivators should consider the impact of regulations in their decisions.

For example, some growers in Santa Barbara County, Calif., are involved in a legal battle with local officials who are aggressively attempting to limit, if not get rid of, cannabis production in their county. When planning out long-term business expansion, factor in both local and global politics and have a plan ready to quickly pivot if political tides shift.

TIP 12: Form relationships with local authorities and neighbors. Go above and beyond to prevent any issues and resolve problems as soon as possible to avoid creating animosity.

TIP 13: Leverage research, product development and innovation. I often ask consulting clients why they choose to do exactly what their competitors do: produce the same things, the same way for often the same price. Be a leader, not a follower. A successful company strives to innovate and develop superior products whenever possible.

TIP 14: Not everyone needs a science degree to innovate. Offer multiple product lines that complement one another without conflicting. I once proposed to a client the possibilities of creating more than one brand line. I asked the client, “What does a customer purchase after they have purchased your two or three products?” To which the client answered, “other companies’ products.”

Understand Desired Genetics

Is your product destined to be sold as flower? For extraction? To be used in specific product formulations?

TIP 15: Growers should select genetics that suit their specific requirements, meaning if their intent is to produce a specific product, grow a plant that produces elevated levels of that compound, whether it’s a cannabinoid or terpene. If growing for flower, then the so-called “bag appeal” of a given cultivar becomes important, and you should be looking for genetics with “traditional” bud structures.

TIP 16: When breeding, select genetics based on lab results and data. Let lab results be a companion to observations when breeding for desirable traits. When scouting phenotypes, take notes, keep records and document (with photos and/or videos) the prospective cultivars to be bred to accumulate as much data as possible to aid in the selection process.

TIP 17: Breeding takes a lot of time and effort, and the payoff isn’t always what growers hoped it would be. Have a clear objective when selecting which cultivars to cross or when breeding the same cultivar with itself. There is no reason for taking a scattershot approach to breeding without a desirable outcome or at least intended beneficial traits in mind.