Temperatures well below zero are blanketing the Midwest this week, and wind chills are making the situation much worse for workers of all stripes. In Chicago, temperatures hovered around -20 degrees Fahrenheit on Wednesday morning.

In Lansing, Mich., the piercing cold greeted the sunrise at -4 degrees.

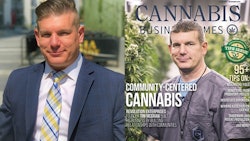

Green Peak Innovations has two state-licensed indoor medical cannabis cultivation facilities in Lansing, and CEO Jeff Radway says the first line of deep-freeze preparation at his company is employee safety.

“As roads get icy and temperatures drop, the first concern is always for our employees,” Radway says. “We want to make sure everyone gets to work in a safe and secure way. Clearly, if [the roads] are not passable or they’re not safe, we ask people to stay home.”

Once the team makes it in, everyone must be attuned to the normal, workaday routines of the facility.

“Cannabis requires a tremendous coordination of design and maintenance, and our grow and facilities team,” Radway says. “The colder weather doesn’t really change our SOPs. It just requires our facilities team to be a little more diligent in terms of making sure that the equipment is running in an optimal way. Michigan is cold in the winter; whether it’s zero degrees or 40-below with the wind chills, we’re expected to see this week, our team has to be on their game at all times.”

"Facility design, whether you’re building a new facility or retrofitting, is of the utmost importance."

- Green Peak Innovations CEO Jeff Radway

Michigan is a secure-transport state, which means that cultivation companies do not transport product from one location to another. Radway says that the licensed transport companies with which Green Peak works have not yet reported any delays this week.

In Buchanan, Mich., the team at Redbud Roots similarly places employee safety at the top of the priority list during inclement weather. Furthermore, the team uses remote monitoring technology to keep tabs on all heating and HVAC systems. Outside, cameras are fixed on HVAC units so that employees can watch out for any buildup of snow.

Farther up the road, in St. Paul, Minn., Wednesday morning temperatures clocked in at -27 degrees. LeafLine Labs, which has four locations across Minnesota’s medical marijuana market, has kept that same level of preparation in mind as it has grown.

“In Minnesota, we are not strangers to extreme temperatures, but it is all about being prepared,” Emily Kowalski, director of cultivation at LeafLine Labs, says. “LeafLine Labs was designed and built for cultivation and production of indoor medical cannabis with Minnesota's climate in mind. With that being said, we are keeping a close eye on our HVAC system this week because of the frigid outdoor temperatures.”

Technology aids this process. Remote communication with automated equipment has become more common in cannabis cultivation facilities; in locations that must contend with cold weather, this capability is even more important.

“We utilize a maintenance company to help ensure that our HVAC system is operating correctly,” Kowalski says. “If any issues arise, we receive text and e-mail alarms from our automation system. Maintaining a proper environment for our plants is extremely important. I will be monitoring our environments closely over the next few days like a farmer would watch over their outdoor crop during a frost warning.”

Diligence, again, is the key word here. And cannabis industry stakeholders like Kowalski and Radway know what sort of climatic challenges the new Midwest landscapes will bring to the industry.

“If you’re going to do business in the upper Midwest, especially where we have severe fluctuations in temperature and humidity, [it’s important] that you spend the extra time planning your facilities,” Radway says. “It’s sort of the old adage: Measure twice, cut once. Facility design, whether you’re building a new facility or retrofitting, is of the utmost importance. We go almost up to 100-percent humidity in the summer, and we go down well, well below zero [degrees] in the winter. The plants like a certain climate every day of the year, so it can be challenging on the facilities, on the mechanical systems and on the team to keep the climate in the sweet spot.”