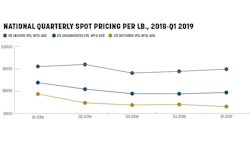

A cannabis business’s profitability can fall fast if owners don’t know how to adapt to the ever-changing market. Market saturation and new customer buying habits can drive prices down and have a significant impact on business strategies. Cannabis Business Times discussed these issues and other trends with three cannabis industry leaders during a panel discussion at the 2019 Cannabis Conference in Las Vegas. The panel participants shared lessons learned and key insights based on their real-world experiences at the conference, which will once again take place in Las Vegas April 21-23, 2020, at the Paris Hotel & Casino.

Panel participants included Leif Abel, co-owner, Greatland Ganja in Kasilof, Alaska; Jesce Horton, founder, LOWD in Portland, Oregon, (and previously founder/CEO of Saints Cannabis); and Scott Reach, founder/COO of RD Industries/Rare Dankness in Denver.

Here are some highlights from the discussion and tips to help other growers thrive in an increasingly complex marketplace.

On Controlling Production Costs

Reach: For us, automation has been very key. A facility of my size, 54,000 square feet—30,000 square feet of canopy space—typically, in Colorado, has between 80 and 90 employees. I effectively run that much space with nine workers, so a lot less overhead on the employment aspect. Throughout my entire company—dispensary, lab, processing, cultivation—there’s a total of about 40 employees. ... So one of the ways that we’ve been able to be cost-effective and been able to just step into a very mature market in Colorado has been through automation and just efficient work practices.

Horton: I think the most important step is how you design the facility. A lot of us are [in] situations where we have to retrofit a facility, a warehouse, whatever that may be and turn it into a cannabis cultivation facility. And a lot of us … have limited budgets. … I think everyone would definitely do themselves a real service if [they thought] about the workflow of what’s happening in that facility. Where is a product moving? How much time are people spending doing their tasks? Are you doing time studies, traditional industrial engineering type of methodologies … to really understand [if] everyone [is] doing things as efficiently as possible?

Abel: For our farm, it comes down to automation and any HR improvements, and improvements in processes that make people more efficient or make it so that a job that was done by a person before can be done by a machine, and then, conversely, you have the side effect of then your people being able to concentrate more on the plants. For us, automation means … automated watering. If you’re not automating your watering, it’s insane the amount of labor you’re going to spend on growing your plants.

On Operations and Selling Value

Reach: In our facility we’ve … made quadrants of every process or flower room. So we make sure that our growers that are involved, or other workers that are involved within that quadrant, understand fully the tasks that are involved within their job description and don’t worry about everything else that goes on within the facility. We give monthly retraining and monthly updates throughout the facility just to keep everybody on the same page. … Keeping all your workers aligned, on task, pushing for the same goal, without worrying about the day-to-day fires that have to be put out, I think, is extremely important.

Horton: You have to be selling on value. You cannot sell on price. If you are trying to survive and trying to essentially beat these bigger players who have the ability to just sell on price, then you’re going be struggling, but if you have the ability to really understand what value you provide—not just to the market but also to your dispensary owner. … Once you’re able to provide that value, then you can do things that other cultivation companies may not be able to do, and essentially you become a partner to that dispensary owner.

Abel: You have to sell more than just cannabis unless you want to be a poor cotton farmer. It’s just that simple. … In order to create product lines, you have to be creative, and you have to have a team that kind of understands what that means. From a cultivator perspective in Alaska, and probably in a lot of places, cultivators can only do so much. … If I’m just selling raw material, I will be at that race to the bottom. We want to sell all these extra services to the retailers.

On Forming Partnerships

Horton: Do you even know what problems that retailer is experiencing on a day-to-day basis? Do you know what they [retailers] really care about? Have you ever asked that retailer, “Hey, what type of problems are you dealing with? What type of solutions ... are working? What types of issues are keeping you up at night?” And there’s your pull right there of how you become a partner for just that simple question of delving down into what bothers [them], and how [they can] become better.

Abel: In our market, partnering and having joint venture agreements with processors is just as important. So another thing that I bring to retailers are specialty products. Our company is really good at helping processors create really unique, innovative products, and then branding it properly, so that retailers have customers coming in and asking for [that product], and then they want to buy it.

Reach: Compliance is becoming such a difficult part of the business that I think a lot of people don’t put enough effort into because, ultimately, if you’re not in compliance, you’re risking your licensing, you’re risking your employees, you’re risking your livelihood. So from the compliance aspect, I went out and actively searched for a partner that would complement me in the areas that we were lacking, which was full compliance, distribution. Once national distribution opens up … having [partners with] deeper pockets than I do is always a benefit.

Horton:As you’re talking about building your brand, I guarantee there are community organizations that align with where you’re going, and you partnering with them would help them to move forward but also would help you and your company to move forward as well. So there is a nonprofit in the city of Portland called the NuLeaf Project that essentially takes money from … the city’s cannabis sales tax and helps to allocate that money toward that organization, which helps get more people of color employed in the cannabis industry, helps black and brown business owners with small grants and things like that to get them more involved in the cannabis industry.

On Key Lessons Learned

Reach: Don’t be so influenced by external noise. Stay true to what your mission is and what your business plan is. ... If you have … something that stands out that adds that value, [then] you can ask for a dollar more or two dollars more or whatever. It’s going to be accepted, and it’s going to be appreciated ultimately as the consumer gets more educated as to what’s actually on the market. For us, it’s just evolve, adapt, overcome. If you can do those three things, you’ll be just fine, no matter what’s going on. If you can’t be fluid, and evolve and adapt, you will go out of business very quickly.

Horton: The first thing I would say is know your market. Really understand the market. Take the time to get involved with industry associations, make networks to understand that market. … Know where you play and know your value; then you can price your product appropriately.