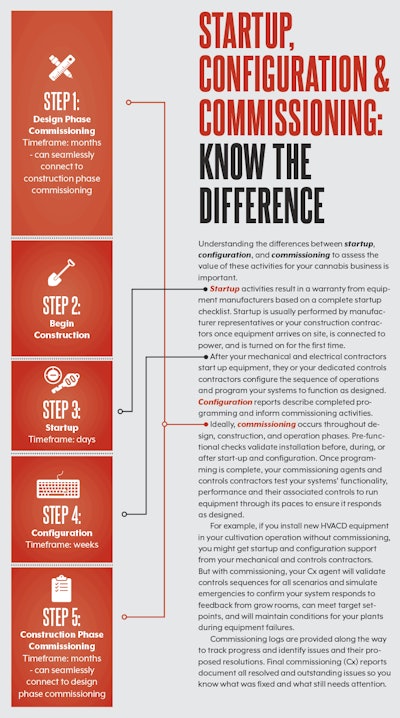

This article is the fourth in a five-part series of guest columns by Resource Innovation Institute (RII). Key terms introduced in this article are italicized and described in more detail in RII’s agriculture best practice guides at ResourceInnovation.org/Resources. RII’s next column will feature snippets from RII’s best practices guides to highlight additional important considerations for growers and the supply chains serving them.

Commissioning (Cx) is a concept born out of shipbuilding; after equipment is installed and tested, issues are identified and corrected, the crew is trained, and the parts, system, and staff of the ship complete a quality assurance process, a ship can be deemed ready for service. A commissioned ship ensured to be in working order is more reliable than an untested ship. Similarly, commissioned equipment that has gone through an extensive quality assurance process is less likely to have manufacturing defects or installation issues that affect operations down the line.

By commissioning your equipment to validate that systems in your cannabis cultivation facility run according to specifications and efficiently, you can reduce operating and maintenance costs for your business and minimize your environmental impact.

Saving OpEx with Cx

When you build or renovate your cultivation facility, you can avoid equipment failure, save energy and improve business outcomes if you commission the affected systems in your building. A 2018 study from the Lawrence Berkeley National Laboratory—a research lab supported by the U.S. Department of Energy through its Office of Science and managed by the University of California—conducted a study evaluating the value of commissioning and its costs for existing and new buildings. The lab analyzed 1,482 commercial and industrial buildings in the United States totaling more than 251 million square feet of renovated existing buildings and more than 22 million square feet of new construction.

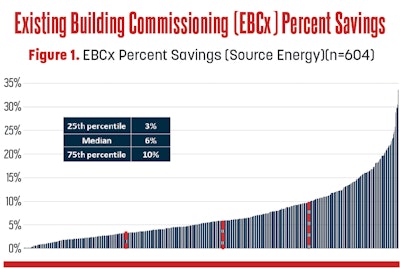

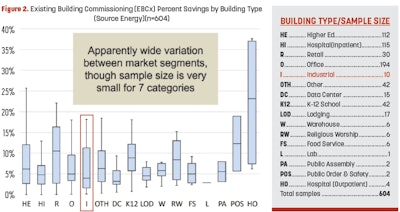

The study found that the median total energy savings for all existing buildings was 6%. For industrial structures, savings hit a median of 4%. Figure 1 (below) summarizes the median (the number that falls in the middle of all responses) total energy savings (including electricity and fuel) achieved in 604 existing building commissioning (EBCx) projects in the study. Figure 2 (p. 64) shows that energy savings in industrial EBCx projects ranged between 3% and 12%. The data suggest that commercial cannabis business operations could save similar amounts of energy and operational expenditures (OpEx).

Commissioning Costs and Return on Investment

The capital expense of hiring a third-party Cx agent to join your team throughout the design, construction, and operation phases of your renovation or new construction project can be a barrier to commissioning building systems. Commissioning scopes can be leaner if the work is performed in-house, but quality assurance activities performed by a third party are more likely to reveal conflicts between trades, installation errors, and functional performance failures than owner-performed commissioning.

The Berkeley Lab study found that costs for new construction commissioning (NCCx) have reduced by 29% to $0.82 per square foot in 2018 (with a typical range of $0.40-$1.35 per square foot), from $1.16 per square foot in 2009. Berkeley Lab researchers also found that EBCx costs in 2018 typically ranged from $0.13-$0.48 per square foot with a median cost of $0.25 per square foot. Therefore, Cx scopes of work are lower today and can make up a median of just 0.25% of overall construction costs.

Typical simple payback periods—the cost of projects divided by their annual savings in operational and maintenance (O&M) costs—of EBCx projects can range from about 1 to 4 years according to the Berkeley Lab, with median payback periods of 2.2 years. A payback period of less than 2 years is attractive even when your business is operating on a lean budget, as the operations and maintenance savings quickly break even and start providing a return on your investment.

Commissioning Cannabis Operations

When designing a new building for your cannabis cultivation, processing, and/or product manufacturing operation, or when replacing mechanical, electrical, or architectural systems in your existing facility, commissioning should be considered along with your design, engineering, and construction contracts.

The purpose of the Cx process is to confirm that the final installation and programming of equipment meets the original design intent and project requirements for your facility.

With improved system performance, your HVAC and dehumidification (HVACD) and lighting systems are tuned to provide optimal indoor environmental conditions for plant growth and health and can function as efficiently as possible.

Cx activities verify your new equipment is ready before moving plants into your growing spaces. Some functional performance tests for cultivation spaces could include overriding actual temperature or relative humidity readings from sensors and observing whether your HVACD equipment responds appropriately to bring conditions back into target ranges. Other tests can include: ensuring sensors are calibrated, running equipment in lights on and lights off conditions, and checking that generators come online during power outages.

Commissioning continues to assist operators once you move your plants in, especially if you use a building automation system to control your HVACD, lighting, and other cultivation processes. During design and construction, your Cx agent can work with you to choose which points are important for you to monitor, which ones to trend and for how long. With the right data stored for useful amounts of time, you can catch problems before they get bigger. Put historical data to good use by benchmarking resource use and corresponding production to track how yield corresponds to facility efficiency.

Commissioning Scope of Work

Cx scopes of work can include the following steps throughout your renovation or new construction project to verify new systems meet the original design intent and performance goals for the facility:

Design Phase Commissioning:

- Review Owner’s Project Requirements (OPR) documents;

- assist design team with creating a Basis of Design;

- develop commissioning plan;

- perform design review of engineering drawings;

- identify issues with building system designs and offer suggested adjustments;

- review equipment submittals.

Construction Phase Commissioning:

- Create and complete pre-functional checklists;

- identify issues with installation and offer suggested adjustments;

- create functional performance tests;

- work with controls contractors to witness and record results of functional tests;

- identify issues with programming and offer suggested adjustments;

- create staff training agendas;

- collect and prepare Operations & Maintenance (O&M) manuals for engineered systems in the building;

- produce final commissioning reports.

Benefits of Commissioning

Cx activities address issues with installation and controls sequences earlier, which can keep your project on schedule, in addition to other benefits noted previously. It is much more expensive to resolve problems once your operation is running.

Both EBCx and NCCx ensure system performance; 78% of new construction projects and 91% of existing building projects studied by the Berkeley Lab in 2018 cited this as a motivation to implement Cx on their project.

Cannabis facilities have mission critical operations, and their building systems should be commissioned to reflect and ensure their business value. Protect your product by verifying equipment is ready for service and get paid back quickly. With commissioning, you can set sail and chart a course for reliable performance and energy savings with reduced O&M expenses.