At CULTA, cannabis genetics are at the heart of every decision the company makes.

The Maryland-based, vertically integrated cannabis company operates cultivation, extraction and processing in Cambridge, in addition to distributing and selling its products at retailers throughout the medical-only state and at its own dispensary in Baltimore.

Research and development are constants at CULTA and, through experimentation, growers have learned that the more than 50 individual cultivars in its genetic library have environmental preferences and require specific conditions to thrive. Plants are carefully preserved in the company’s in-house tissue culture lab, which was launched in 2021 to nurture its cannabis cultivars and protect them from pathogens and genetic drift, says Jay Bouton, CULTA’s senior director of cultivation.

“We spend a lot of time and energy finding specific phenotypes that we keep in our library, and this gives us the ability to keep them safe for longer than your typical mother plant’s lifecycle,” Bouton says.

Once the plants leave the tissue culture lab and move to propagation, vegetation and flowering, their journeys vary. CULTA has a mix of growing environments, growing both indoors and tending to 3 acres outdoors, monitoring the plants’ performances in the various spaces, Bouton says.

“Over the course of four years of growing indoors, and four seasons of outdoor cultivation, we have found that genetics play a large role in how successful the crop will be depending on its environment,” Bouton says. “For outdoor, pest and pathogen resistance are key, especially for us here in Cambridge, Maryland, where humidity is routinely above 70% in the peak summer months.”

Indoors, CULTA maximizes space in its 20,000-square-foot facility using three-tier vertical growing systems in vegetative rooms and two tiers in some flowering rooms that are equipped with light-emitting diode (LED) lights. The company is intentional about where plants are placed within the tiers.

“We have found that certain strains like the top tiers of our racking system because they handle slightly warmer temperatures and don’t require quite as much water throughout the day,” Bouton says.

Temperature also comes into play when working with different lighting systems. CULTA’s original grow rooms had high-pressure sodium (HPS) lighting but, over the years, the facility has added more LED capability to its cultivation facility, Bouton says. Both lighting systems play an important role in CULTA’s cultivation strategy.

“We have found certain strains do prefer different [spectra] of light …. Every room we have brought online since 2020 has had LED lighting,” Bouton says. “We find that some strains show their unique expressions better under HPS lighting, and we choose to keep them growing under that spectrum to continue to see those differences. We run our LED rooms slightly warmer than our HPS rooms to account for the loss of heat load from the HPS lights and to keep the leaf temperatures at optimal levels.”

Optimizing the conditions at various growth stages and watching for plant preferences have helped the company better dial in the various cultivars’ growth habits and yields, Bouton says. Cultivars under LED lights tend to produce denser flower, for example, while plants illuminated with HPS have varied habits.

“Strains that have unique traits, like more bulbous calyxes, tend to fill out differently under the HPS spectrum, so the structure of some strains’ flowers can be more visually appealing in those rooms,” Bouton says. “We have also seen that strains that have more sativa-based genetics, especially ones that like to stretch, like Poochie Love, don’t mature in the same way under the LED lights, so we keep them under the HPS spectrum.”

Cannabis cultivars also have specific lighting needs in the in-house tissue culture lab, where low-intensity LEDs are critical in plants’ infancy stage, Bouton says.

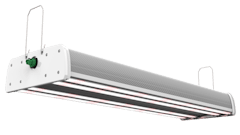

“The lighting needed for the tissue culture lab is still very important but doesn’t need to be as intense,” he says. “We use single bar LEDs to light our tissue culture explants with a maximum of 100 PPFD.”

“... We have found that genetics play a large role in how successful the crop will be depending on its environment.” – Jay Bouton, senior director of cultivation, CULTA

The LED lights also help the team maximize space and operate more efficiently, says Michelle Sprawls, CULTA’s director of science.

“In micropropagation, plants are cultivated aseptically in culture vessels, typically in a multi-tier culture room that is outfitted with LED lights. Arranging the LED lights on tiers allows large numbers of cuttings to be maintained in a very small space, thereby reducing the amount of floor space required …,” Sprawls says. “Lighting is an important part of the tissue culture process as it drives the reaction of photosynthesis. LED is becoming more common in the application of tissue culture because it features high efficiency, low energy, safety, reliability, and intensity flexibility.”

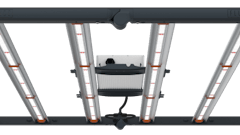

While overhead lighting is the norm in cannabis cultivation, using LED technology, CULTA is also experimenting with side lighting and monitoring the results. Bouton is hopeful this can help the company increase yield and overall efficiency.

“We just began a new trial with a company that is introducing side lighting with LEDs in combination with the existing overhead lighting in hopes of increasing yields of usable biomass under the canopy,” Bouton says. He could not share details about the trial parameters, he said, including if they are installing lighting in flowering rooms exclusively or how long they are trialing this strategy, until after data is available. “Many companies have introduced under-canopy lighting recently, but most are installed on the tables looking directly up at the plants. We are hoping the light penetrates the canopy better than under lighting, and hits the top of the leaves, rather than under, where the stomata are.”

Bouton says this approach of carefully monitoring the grow rooms and outdoor cultivation has helped drive CULTA’s success in Maryland’s medical cannabis market.

“[The] advice I would give to other growers is to pay as much attention to your environment as possible,” he says. “If you can get your environment dialed in to fit your situation, your rooms will be much happier over time.”