Over the past few years, LED lighting fixtures’ efficiency in converting energy into light has compelled more industries to adapt LED technology to purpose-built solutions, such as those being used for horticulture and the cannabis industry.

As LEDs have continued to develop, they have begun producing more consistent yields, according to Dung Duong, chief innovation officer for Fluence Bioengineering.

“More consistent yields, whether that’s color, flux or voltage, have allowed for cost reductions across the industry,” Duong says. “Efficacy gains over the past few years can principally be attributed to larger LED chips being used in lower-cost packages.”

LEDs take electric current and convert electrons into photons of light, using semiconducting materials to adjust the energy level of an electron to make it useful for lighting, Duong says.

“This is what makes LEDs the most energy efficient form of lighting possible; no other lighting technology can provide a direct conversion of one electron into one photon of light,” he adds.

Although the science behind LEDs has not changed much since their invention, the efficiency and increasing adoption of LEDs have helped the technology progress in the past few years, Duong says. “This adoption has brought down cost significantly, which enables the industry to use more semiconducting materials and create very efficient LEDs,” he says. “This has been a key development for LEDs to displace every other competing lighting technology and make LEDs viable for horticulture.”

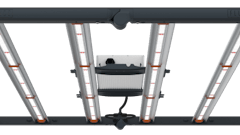

For example, Fluence’s SPYDR model has evolved since its initial launch in September 2012, when it had an efficiency rating of 1.67 µmol/J, or 1.67 micromoles of photons per joule of electricity, and an output of 1,200 photosynthetic photon flux (PPF). Now, the newer model, the SPYDR 2i, which launched in August, has an efficiency rating of 2.7 µmol/J and an output of 1,700 PPF.

“As LED technology has improved, energy efficiency and light intensity have been the two primary ways customers have seen the benefit,” Duong says. “The marked improvement in energy efficiency will save customers millions in operating costs and the incremental intensity improvements are also seeing higher yields."