Labor and energy are typically the two highest operating costs for cultivators, according to Fluence Bioengineering’s VP of Marketing Travis Williams. Increasing lighting efficiency can not only increase overall revenue and production, but help decrease energy and real estate costs and thus reduce operating costs for production, Williams says. Here, he shares three ways to accomplish this.

1. Reduce power consumption.

Williams says the standard lighting system in use today consists of 1,000-watt, double-ended high-pressure sodium (HPS) lights, and most growers will consume 1,000 (or even up to 1,100) watts per 16 square-feet of canopy space.

“Not only do you have the electric draw out of the wall for 1,000 watts, but then you also have your HVAC system consuming energy directly correlated to the amount of power your lights are consuming to manage the environmental climate within that room,” Williams says.

For every watt of energy going into a lighting system, Williams says, the HVAC in the facility needs to manage the thermal load to maintain the optimized environment. He also adds that radiant heat emitted by HPS lights adds an additional factor to mitigate with a robust HVAC system when it comes to optimizing leaf surface temperature.

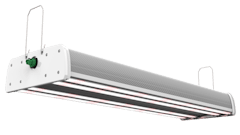

Williams recommends an LED lighting system that is a direct replacement of the 1,000-watt, double-ended HPS system that uses only 660 watts and provides higher light intensities with a lower consumption of energy.

“[That] not only reduces the amount of energy required to deliver optimal light levels to a crop, but it also dramatically reduces the amount of energy required for the HVAC system because you do not have to offset the radiant heat from HPS and ultimately account for fewer watts in the growing environment,” Williams says.

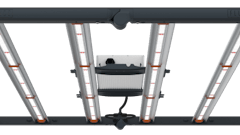

2. Increase coefficient of utilization.

Ensuring that the light generated from a fixture reaches the crop is another way to increase lighting efficiency and decrease energy costs, Williams says.

“Today’s standard lighting strategy in an indoor cannabis farm is what we call high bay lighting,” he says. “Light fixtures are mounted high above the canopy, roughly 3 or 4 feet, and broadly distribute light across the entire room. Almost no matter where you are in your room, you’re going to receive the same amount of light, including walls and aisles. You’re wasting energy and money every time a photon lands on an object other than a plant.”

Williams says a unit called the coefficient of utilization (CU) measures the percentage of light that reaches the target area (i.e. plant canopy) against the total amount of light generated by a light fixture. The higher the CU, the more efficient the lighting solution.

“Ideally every photon that’s emitted from your fixture lands on a plant leaf,” he says. “Deploying a lighting design that provides even distribution across your canopy with minimal wasted light on aisle, walls and egress will further increase efficiency and reduce operating costs.”

“Every photon that’s generated from a light fixture requires energy to create it,” he adds. “Every photon of light that’s hitting a wall or an aisle instead of a plant is wasted energy, and that’s wasted money. New lighting systems have optics and form factors that can significantly increase the CU compared to traditional HPS.”

3. Balance inputs and outputs.

Operating costs should be analyzed as a secondary metric after primary yield numbers are achieved, and growers should be willing to increase energy consumption as necessary to achieve higher yield, Williams says.

In a greenhouse, for example, supplemental lighting can be added to dramatically increase yield, consistency and quality, especially during winter months with less sunlight, he adds. In this case, cultivators may be able to increase production beyond increased operating costs and have a net positive revenue and overall higher efficiency.

“Operating costs might go up due to incorporation of new technologies that consume energy, but yield and output will increase far more,” Williams says. “Cultivators should balance their inputs and outputs to strive for higher efficiency, not just lower consumption.”

Top photo courtesy of Fluence Bioengineering