Growing cannabis without soil can be a successful endeavor if you know where to start in your hydroponic system selection. In part one of this series, we explored substrate-based hydroponics and related terms such as inert substrates, cation exchange capacity (CEC) and the pour-through method for monitoring pH and electrical conductivity, as well as the origins of hydroponic growing. (Editor’s note: To read part one, visit bit.ly/hydroponics-part-one). In this column, we’ll cover water-based hydroponic systems and look toward the future of these growing methods.

Deep Water Culture (DWC)

In deep water culture (DWC), plant roots are perpetually submerged in a nutrient solution. Think of DWC as ebb-and-flow without the “ebb.” In fact, the commercial kits for table-sized DWC are nearly identical to ebb-and-flow kits with one exception: Ebb-and-flow kits come with a timer to operate the pump in the nutrient solution reservoir intermittently, while the DWC kits typically continuously circulate the nutrient solution between table and reservoir.

Substrate is rarely used in DWC. I have seen systems with marble-sized clay pellets, but most substrate would float out of the submerged pots and clog filters. More typically, plants float on Styrofoam rafts, their crowns wedged in holes drilled in staggered rows. The plants are propagated elsewhere and transplanted when roots are long enough to be submerged.

Alternatively, seed can be sown directly in the rafts. Slits are filled with a very small amount of finely graded (i.e., well-grated) peat or coir germination substrate. BrightFarms, one of the largest hydroponic leafy green producers in the country, utilizes this raft system with soccer field-size ponds inside its massive greenhouses. Seeds are sown daily in rafts and floated on one end. Rafts are pushed along with large paddles to make room for the new trays. Harvesting takes place daily on the other end, making room for a new planting. Many of the company’s greens only require about two to three weeks of growth before they are ready for harvest, versus the typical 30-day to 45-day life cycle for leaf lettuce with field production.

Plant roots require oxygen for respiration. Oxygen is a key component of the energy creation process for cellular repair and nutrient uptake. Oxygen is also needed to limit anaerobic bacteria and fungi that could cause stress or disease. It can be dissolved into the water by bubblers, agitators, fountains (such as those found in fish tanks) or simply by the return water splashing into the reservoir. It can also be introduced by the breakdown of hydrogen peroxide products or ozone injection. Regardless of the method and the size of reservoir, oxygen content of the water should be monitored with a fixed or hand-held meter ($200 to $300) and maintained at more than 5 mg/L. The solubility of oxygen in water decreases with temperature, so warm greenhouses are especially prone to low levels of water-dissolved oxygen.

It’s worth mentioning that DWC is the primary choice for plant nutrition research, as the available nutrients or amendments can be nearly perfectly controlled and traced. Plant nutrition studies in substrates are frequently fraught with error caused by the interaction of the substrate with the solution; and typically, the roots need to be cleanly harvested for lab analysis. Each treatment group—even each plant—may have its own little tub of solution that needs daily adjustment for these experiments. Though it isn’t easy, DWC cultivation is the source of much of the plant nutrition information growers rely on today.

High planting densities can be achieved with DWC. Other advantages include unlikelihood of catastrophic water stress from a failed pump, and the relative stability of pH, nutrient level and water temperature provided by such large volumes of water. Challenges include aeration and algae control, high humidity and a wet environment conducive to some pests. Also, capital investment is typically much higher for a professional installation of DWC.

Nutrient Film Technique (NFT)

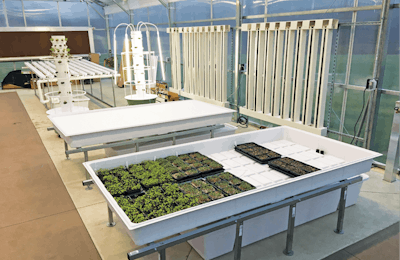

This technique, commonly abbreviated as NFT, is by far the most popular water-based hydroponics system. It is perfectly suited for lettuce, the most commonly produced hydroponic crop in America. Plants are grown in tightly spaced, rectangular troughs, the roots dangling into the bottom where they grow in a thin film of nutrient solution. The solution flows downward on a 1-percent to 2-percent slope to where it drains into a reservoir before being pumped back up to the high end of the troughs. In small systems, water collects in a reservoir under the table, and pH is adjusted with acids or buffers multiple times per week. Nutrient solution is replenished as it is used up and completely replaced every seven to 14 days.

Several companies sell these systems in modular kits. Of course, like any hydroponic system, NFT systems can be built from locally supplied rain gutters or PVC pipe. The devil is always in the details with do-it-yourself, though.

Interesting vertical variations of NFT can be constructed or purchased. “Vertical farm walls” are like NFT systems turned on their end. Plants are planted sideways in the vertical gutters, wedged in a slit between two pieces of open-weave plastic substrate and a layer of capillary felt. Water trickles down from above through this substrate where the roots grow, making this a combination of NFT and capillary watering (sub-irrigation). The reservoir is a bit small, but the space utilization is remarkable—double that of an NFT set-up, which typically has more than four lettuce heads per square foot of floor space.

Another vertical style is the serpentine rack. These are made of 4-inch-by-6-inch PVC pipes connected in a zigzag of descending rows, creating one long, serpentine gutter on either side of an A-frame support stand.

A third style is the Tower Garden, which is comprised of vertical plastic columns of roughly 12 inches in diameter—with planting holes distributed evenly—attached to a 20-gallon reservoir with a pump. Via a submerged pump in the bottom of the reservoir, nutrient solution is sent upward through the center of the column, where it drips down through a series of sieves that distribute the droplets effectively to the roots of all the plants along the column perimeter.

NFT is not often seen in use for cannabis production, as it can’t support large root systems. It may be worth testing out for auto-flowering cultivars (which are typically smaller). In general, water-based hydroponics are too expensive and labor-intensive for growing crops beyond leafy greens and herbs. GW Pharmaceuticals, the United Kingdom company that makes cannabis medicine Sativex, reported experimenting with water-based hydroponics and abandoning the effort.

Aeroponics

Aeroponics is very familiar to cannabis growers, as many have used specialized aeroponic systems for rooting clones. In aeroponic systems, a pump sprays a fine mist on plant roots rather than submerging them in nutrient solution or planting them in a substrate. Other than that, aeroponic systems operate with components similar to those used in hydroponics. They also require similar maintenance, with one exception: Aeration is not required because the roots suspend in air when not being misted.

A 2018 research study from Texas A&M University comparing rooting with aeroponics, water-based hydroponics and substrate production, reported “remarkably greater root growth with a significantly greater root biomass” with aeroponics. However, at least under the conditions of their study, this did not lead to greater shoot growth than hydroponics.

AeroFarms is a massive vertical farm in Newark, N.J., that utilizes aeroponics for leafy greens production. It is a jaw-dropping sight, with 20 rows of 35-foot racks, each with 13 layers of aeroponic tables—all lit with LED bars. Many people are also familiar with aeroponics if they have visited Disney World’s “The Land” exhibit. Aeroponics has also been an important research tool for decades. Plant physiologists especially like that the root structure better represents how roots grow in nature.

One note of caution: Preventing pump failure is much more important in aeroponics than hydroponics. If the misting fails, the onset of water and nutrient stress is very quick because no part of the root system is in contact with liquid water or moist substrate.

Aquaponics

Aquaponics combines DWC hydroponics with aquaculture—the rearing of aquatic animals or aquatic plants. This provides two income streams for the grower: fresh fish and organically grown plants. Leafy greens and herbs are typical plants grown using aquaponics, and common fish reared are tilapia, rainbow trout or catfish. It is well-suited for organic production, as the fish provide the nitrogen the plants need.

This is how it works: Two systems are connected in a recirculating loop. Consider the fish tank as the nutrient solution reservoir. Water from that tank is pumped into the hydroponics tank (which usually sits higher than the fish tank), but not before being filtered for sediment and channeled through a column containing nitrifying bacteria. The bacteria convert the nitrogen from urea form (fish urine) into the nitrate form (food) that plants use for growth. The plant roots help purify the water before the runoff drips back into the fish tank. That is a simplified explanation for a complex living system. As the system matures and the nitrifying bacteria increase in the columns, plant yield increases.

We built six aquaponics systems side-by-side from experimentation at Purdue University and, though it continues to be a successful project, they have proved to be one of the most difficult systems to manage, requiring many specialists to build and a team effort to maintain. Here’s my take: Growing productive plants using hydroponics is difficult. Rearing fish indoors is hard. Putting both systems in the same space makes both of them more difficult, as the presence of fish makes nearly every pesticide off limits due to their sensitivity to chemicals. Putting them both in the same space and connecting them together in symbiosis in a way that can create a profit margin is nothing short of a feat. In my opinion, that is why we don’t see a lot of these operations.

Aquaponics does have one attribute that other systems can’t boast, though, and that is public interest. The reason: Fish move, plants don’t. The fish tanks can have little viewing windows and people can even feed the fish. It makes for visually exciting and interactive tours while the science and environmentalism makes a fascinating lesson. I can imagine a clever entrepreneur could combine quality cannabis cultivars, gourmet seafood dining and technology tours into a thriving agritourism destination.

Future Forecast

One aspect of growing plants in water is the ability to monitor root growth like you never have before. It can be quite a transformative experience. While I don’t foresee water-based hydroponics replacing drip irrigation or ebb-and-flow systems, they may have their own unique niches in the cannabis industry for research, propagation and specialized products.

For example, if an additive or nutrient is found to improve a medicinal compound in cannabis by uptake from roots, the additive may be far more efficiently available to the roots if they are suspended in a liquid solution containing it, or if the root biomass is increased using aeroponics. Another scenario could be that root temperature increases uptake of a specific additive or nutrient, resulting in a desired effect on plant chemistry. A deep water culture system could be chilled or heated quite precisely, independent of air temperature. Increased yield of the target chemistry may then justify the production and maintenance costs of a water-based system.

The discoveries are there to be made, if you dare make them.