The nascent cannabis industry has grown with a focus on raising capital for brand development and distribution. But during the past year, the industry has experienced growing pains that could signal a need to place a greater emphasis on profitability as production costs continue to drive down business valuations.

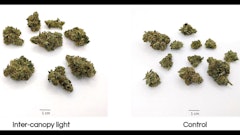

The use of natural resources in cannabis cultivation and processing has a significant impact on production costs. Energy remains one of the greatest resource demands for controlled cultivation environments. Cultivators who take steps to manage energy consumption in their operations can optimize their production methods, which, in turn, leads to lower operational costs and can increase valuations.

Historically, knowledge transfer about efficient production methods via word-of-mouth served parts of the industry well throughout its illicit and newly regulated stages. Today, as more cannabis companies consider global models and predict further pressure on operating expenses, more objective and robust information is needed to achieve efficiency and resource conservation.

To accomplish this, industrywide collaboration is critical. There are three key reasons why the industry should unite to raise the bar on sharing and comparing best practices for production:

1. It is in everyone’s best interest to improve efficiency.

As the industry consolidates and globalizes, cost structures are demanding efficiency. This is the moment in time to improve the industry’s reputation as a responsible actor on energy, water, waste and carbon emissions. Regulation is unavoidable, but codes and standards should be shaped by informed cultivators and their trusted supply chain partners. Better yet, a self-governed industry effectively promoting efficient use of resources is likely to be less regulated.

2. Collaboration is the way forward.

While many cultivators, engineers, manufacturers and consultants have deep knowledge in certain areas of the building systems that affect operational efficiency of grow facilities, the industry has a noticeable lack of understanding of interactive effects, which entail the way one building system can affect energy consumption of another. One example is how heat given off from lighting systems requires different cooling strategies when lights are on compared to when lights are off.

The supply chain and key market players need more sources of reliable and trustworthy information. Multidisciplinary perspectives are critical to achieving the depth of understanding necessary to make a substantial impact on the energy consumption and resource demands of cannabis cultivation facilities.

3. Objective guidance is critical.

Very few research or peer-reviewed resources exist to help guide the cannabis industry. While manufacturer-created content such as cultivation guides or manuals can be helpful, it has its limitations. Recommendations published in media reports are essential to an informed marketplace. Yet, because they are most successfully delivered in bite-sized chunks, they often overlook the variety and complexity of building systems. It’s one thing to install efficient technology or design an efficient facility; it’s another to operate it efficiently.

The Resource Innovation Institute (RII) began tackling this problem this past summer when it issued applications for participation in two working groups within its Technical Advisory Council (TAC). One group focuses on lighting systems and the other group focuses on heating, ventilation and air conditioning (HVAC) systems. RII invited more than 25 organizations to participate in developing brand-agnostic and expert-level content that would be helpful and digestible to growers and their project teams. Over the course of six months and 20 meetings, the TACs met to discuss relevant key terms and definitions, determine energy performance metrics, and define best practices for two major systems that contribute greatly to the energy consumption of cultivation facilities.

This collaborative process resulted in RII publishing two Best Practices Guides:

- “LED Lighting for Cannabis Cultivation and Controlled Environment Agriculture”

- “HVAC for Cannabis Cultivation and Controlled Environment Agriculture”

Both guides seek to educate the market on a number of best practices, including: standardized terms and definitions for lighting and HVAC systems; assembling effective project teams; how to review manufacturers’ literature; crucial considerations when selecting equipment; and how to install and operate successful lighting and HVAC solutions in alignment with business models.

RII designed the guides as companion publications. For example, a cultivator considering converting its facility’s lighting system to LEDs would also want to learn about the interactive effects and associated changes in HVAC system operation.

When cultivators and their project teams use the recommendations of the Best Practices Guides to inform their decision-making during the planning, design, construction and operation phases of a new construction or renovation project, they will be empowered to achieve greater operational efficiencies in their facilities.

This is the moment in time to improve the industry’s reputation as a responsible actor on energy, water, waste and carbon emissions.

Efficient Facilities are More Profitable

The benefits of higher operational efficiencies are lower production and overhead costs. Additional benefits include the ability to comply with new and planned regulations and the ability to take advantage of incentives that drive down capital expenditures for purchasing energy-efficient equipment. Whichever reason for pursuing operational efficiencies, vetted best practices will set cultivators up for success.

Operational efficiency metrics—such as grams per kilowatt hours, or kBtu—are being introduced in the cannabis market, as in other sectors. Some states are incorporating these metrics into energy codes and are going so far as to require owners and operators of grow facilities to engage with utilities and their energy efficiency programs. Mandating that facilities comply with aggressive targets for lighting power is the stick, and robust incentive offerings from utilities for LED lighting systems and controls strategies is the carrot.

In the near future, cannabis facilities might be required to report the energy impact and carbon emissions associated with their products and operations. In support of such a requirement, utilities nationwide would need to amplify and escalate their offerings to cultivators to provide incentives for energy efficiency and resource conservation.

Working with utility companies may be a new concept to some cultivators, especially after spending many years avoiding them. In this new era of cannabis legalization, cultivation facility operators have much to gain from opening the lines of communication and learning what rebate programs and custom support are available in their region.

Times have surely changed! Utility companies across North America are eager to show growers that they are making the effort to understand them and their needs before suggesting what equipment they should install and how it might work for their business model. Energy efficiency programs also are being thoughtfully developed and deployed for cultivation facilities for LED lighting products and high-performance HVAC and dehumidification equipment, and more unique incentives will become available if growers maintain relationships with their utilities and ask for custom support.

Only the best operators will survive in this competitive market. If cultivation facility owners develop and follow internal business improvement procedures that increase operational efficiency and advance quality control standards, the entire industry will have successfully taken the next step toward resource-efficient cultivation.

Knowledge-Sharing is Everyone’s Responsibility

To educate the marketplace with an accessible approach, cultivators should seek resources, such as industry trade publications like Cannabis Business Times, that publish the recommendations of technical experts and university researchers in more general language for the cannabis community to absorb, understand and apply to existing and future facility design.

The Facilities Design Committee of the National Cannabis Industry Association (NCIA) also has committed to promoting the Best Practices Guides to provide access to resources for NCIA members, the larger cannabis community and regulators. The goal is to inform its members about the design and use of sustainable and operationally efficient facilities using Good Manufacturing Practices to help the cannabis industry compete in the global marketplace.

Throughout the year, Cannabis Business Times will feature snippets from RII’s Best Practices Guides to highlight important considerations for growers and the supply chains serving them. Upcoming articles will be curated by Gretchen Schimelpfenig, RII’s technical director, and will feature members of RII’s Technical Advisory Council.