When growing cannabis in greenhouses, the need for supplemental lighting may be lower than for indoor facilities, but lighting demands vary depending on location. Facilities located in regions with shorter days and less available sunlight may use supplemental lighting solutions for more days of the year, or at higher intensities, to meet targets for optimal cannabis production.

The Resource Innovation Institute (RII) has gathered members of its Technical Advisory Council into working groups to develop best practices guides for controlled environment agriculture since 2019, when we published our Lighting Best Practices Guide for Cannabis Cultivation. The Key Horticultural Lighting Terms companion to the lighting guide helps growers and project teams use a common language to design systems for cultivation operations.

How Cannabis Uses Light

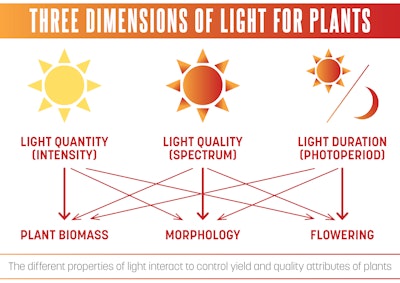

Recommended practices for horticultural lighting design are improving outcomes for plants and growers. It is now well documented that all plants respond to light with wavelengths from UV (280 nm) to far-red (800 nm), and that photosynthesis is triggered by photons in the PAR range (400 to 700 nm).

Light intensity and spectral treatments influence plant growth and development both directly and indirectly. In the image above, Dr. Erik Runkle, Michigan State University professor and developer of MSU’s Controlled-Environment Lighting Laboratory, describes how three major dimensions of light (intensity, spectrum, and photoperiod) correlate to changes in yield and quality attributes.

Different properties of light interact in greenhouses. Sunlight has photons from a range of wavelengths and varies in intensity throughout the day and photoperiod throughout the year. Supplemental lighting systems can be diverse in their spectral distribution and can be operated at varying light intensities and customized photoperiods.

Document Greenhouse Lighting Needs

As you design your greenhouse lighting systems, it is crucial to collect important details such as daily light integral (DLI) and photosynthetic photon flux density (PPFD), and account for other significant variables outlined in the following nine tips.

1. Determine available sunlight at facility locations.

Review DLI received at greenhouse locations for each month of the year. The amount of daylight and associated supplemental lighting needed to reach target DLI fluctuate, so identify minimum and maximum values to inform supplemental lighting design. DLI maps for the U.S. are accessible online.

2. Account for light transmission of greenhouse coverings.

Glazing materials with lower visible transmittance (VT) can increase greenhouse supplemental lighting needs. Some greenhouses with specialized coatings allow sunlight to achieve target light levels for crops during parts of the year without using any supplemental lighting. Review product specification sheets and consider how VT might be reduced over time as coverings age.

3. Calculate supplemental lighting needs.

To quantify how much sunlight a greenhouse canopy receives throughout the year, reduce solar DLI for each month by VT%. For example, if a facility receives 30 mols (moles of light) of sunlight per square meter (m2) per day in March, but a covering has a visible light transmittance of 66%, only 20 mols per square meter make it into the greenhouse each day of that month. If this example flowering cannabis greenhouse has a DLI target of 35 mols per square meter per day, 15 mols/m2/day must be provided with supplemental lighting systems (equal to the difference between DLI target and DLI received from sunlight.)

4. Set maximum usable light intensity.

Balance yield and quality by understanding the peak light intensity at which your cultivars perform best. Document the high limits of your plants by stage of growth to effectively estimate necessary supplemental lighting system operation. For flowering cannabis, PPFD of >1,000 µmol/m²/sec may be feasible, but younger plants develop better with lower light intensities.

5. Target DLI by stage of growth.

Determine crop needs based on cultivar and growth stage. Consider how you might supplement daylight. For example, will top lighting be used alone or alongside intra-canopy lighting systems? Set DLI targets for cultivation spaces and understand how much light different systems might provide.

6. Create lighting schedules.

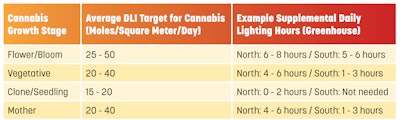

To maximize yield, understand how long to run electric lighting to supplement available daylight. Document monthly or weekly schedules for supplemental lighting operation based on available sunlight, greenhouse covering VT, the maximum usable light intensity of crops, and target DLI for your plants by growth stage. The table featured above (from RII’s Automation & Controls Best Practices for Cannabis Cultivation) offers typical ranges for DLI targets and daily hours of supplemental lighting system operation. Note that different ranges are provided for the northern and southern U.S.

7. Choose a lighting system type.

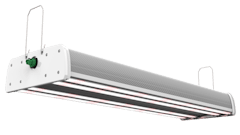

Estimate impacts on electricity usage and understand energy savings. LED horticultural lighting can have higher photosynthetic photon efficacy (PPE) and lower operational costs. Energy savings from LEDs can provide return on investment for higher initial costs in several years depending on greenhouse location and energy efficiency program rebates. LED lighting for cannabis cultivation has become more widely accepted for a variety of reasons like energy efficiency, productivity, choice, pricing, utility programs, regulations, and transparency.

8. Choose third-party certified LED products.

Picking the best horticultural lighting equipment has never been easier. Since 2018, the DesignLights Consortium (DLC) has been certifying LED horticultural light fixtures, and in 2021, it began to certify LED replacement lamps for fluorescent and high-intensity discharge fixtures. Now over 550 LED products tested and listed in the DLC Qualified Products Library.

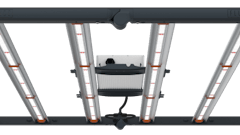

9. Optimize light fixture form factor.

LED horticultural light fixtures come in a variety of sizes, shapes, and other specifications. Because of the layout and arrangements of greenhouses, the shape of a light fixture can impact how it is mounted and how it shades crop canopy. Larger fixtures mounted close to the plant canopy may block daylight. A thoughtful combination of fixture choice and mounting height can minimize shadow footprint.