Just five years ago, Illicit Gardens Chief Operating Officer Adam Diltz would not have considered using LED lights for his cannabis grow. Citing past grows for different companies, Diltz recalls high-pressure sodium (HPS) fixtures delivering better yields and bud structure than LEDs.

However, as time passed and Diltz found the right LED company, he changed his tune. Illicit, which launched Kansas City’s first legal cannabis harvest in 2020, is now partnering with Las Vegas-based Fohse, a manufacturer of high-performance LED grow lights designed specifically for the cannabis industry.

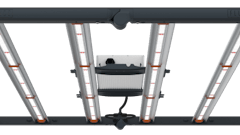

Illicit utilizes Fohse’s flagship 1,500-watt A3i lights for 18 flower rooms that comprise 30,000 square feet of growing canopy. Illicit has 63 Fohse fixtures in each space, with three lights providing tremendous canopy penetration for each individual 5x20 grow table.

“Fohse’s wattage and its ability to swivel spreads that light map out wider,” Diltz says. “Though their fixtures go up to 1,500 watts, we generally have them at 80%-85%. We’ll play with the intensity a bit if a plant is shorter or taller.”

Most artificial light sources offer only straight up and down saturation, whereas the V-shape distribution of Fohse lights is ideal for thicker canopies. Multiple spectrums are an additional advantage of Fohse lights, Diltz notes.

“The big thing about lighting is there are hundreds of companies in the market,” Diltz says. “The reason people go with Fohse is you know they’re not going anywhere. Anytime we make an important decision about equipment or lighting, we want to make sure it comes from a company that has longevity in the space.”

Illicit initially purchased 1,200 A3i fixtures, enjoying a reliable product that has rarely needed replacement and ongoing cost savings, according to Diltz. Compared to Diltz's previous grows, Illicit has 30% fewer light fixtures per room, reduced energy costs by more than 50% compared to HPS, and saved about 10% in energy costs compared to other LEDs. The lights, requiring fewer fixtures, along with other state-of-the-art design efficiencies, aided in Illicit securing nearly $1 million in rebates from its energy provider, according to Diltz.

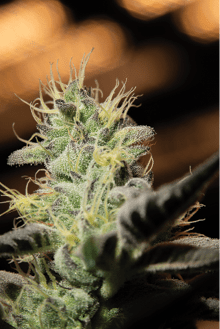

Significant coverage and spectrum control gives Illicit upwards of 96 grams of usable product per square foot, with some cultivars consistently reaching over 115 grams per square foot (some have even produced as much as 130 grams per square foot), Diltz says. High-performance lighting, married with the company’s well- established breeding techniques, has also resulted in steady 3%-9% terpene concentration and a higher cannabinoid profile, he adds.

“Looking at VPD [vapor pressure deficit] or surface temperature, you follow different scales depending on the lighting,” Diltz says. “With A3is, we lean more toward growing the way we always did under HPS, without having to make changes across the entire grow. We’re able to keep doing what we’ve always been familiar with.”

While Illicit painlessly integrated the lighting technology into a third-party cultivation control system, Fohse engineers were on call to ensure the process went smoothly.

“They’ve answered the phone anytime we called,” Diltz says. “And anytime we had an issue with a couple of lights, they shipped out a replacement the next day.”

As good lighting is foundational for any grow, Diltz lauds Fohse for allowing his experienced team to maintain its already superb production level.

“We were good at what we did before this, but Fohse has helped make sure our flower has the highest cannabinoid and terpene profile so we can keep a top-shelf price point,” Diltz says.