Hawaii is America’s Pacific paradise, a chain of islands known for its stunning beaches, high-end shopping and water sports. It’s also the birthplace to some of the cannabis industry’s most legendary varieties, including Maui Wowie, Hawaiian, Kona Gold and Puna Budder, to name but a few.

Those who are unfamiliar with the Hawaiian islands may think they are pretty homogeneous, but nothing could be further from the truth. Each of the state’s five main islands has its own distinct challenges and realities, from geographies to economies. Take for example O‘ahu and the Big Island (Hawai‘i Island): O‘ahu is the state’s tourism hub, a smaller island that typically takes an hour to drive from end-to-end (with some variance based on traffic, which is notoriously bad). The Big Island, for its part, represents more than 60% of the total land mass of Hawai‘i (in the proper native spelling) and is roughly the size of Connecticut.

Understanding the state’s cannabis market, therefore, requires in depth knowledge of these communities and the challenges they and Hawaiian cannabis operators face. For example, each of the state’s eight cannabis companies is vertically integrated and cannot wholesale to other licensees. Additionally, licensees cannot operate a cultivation facility or dispensary on multiple islands.

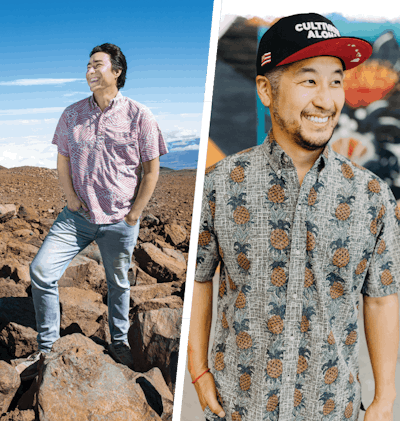

Here, Noah Phillips, chief compliance officer for Hawaiian Ethos, based on the Big Island, and TY Cheng, president of Aloha Green Apothecary, which operates on O‘ahu, interview each other on how their companies have navigated the unique challenges of cultivating cannabis in a tropical island environment, how the regulations influence competition amongst licensees, how they’ve tried to create niches for their companies while remaining jacks-of-all-trades, and more.

Editor’s note: This interview has been edited for length, style and clarity.

TY Cheng: Tell me, how did you get involved in the Hawaiian cannabis industry?

Noah Phillips: Back when I was doing my law degree, I was taking this high growth entrepreneurship class. And one of the assignments was identifying a potentially a high growth industry for Hawai‘i that has longevity. And the topic that I chose was cannabis. As Hawai‘i legalized the medical program, the opportunity was presented for me to join this company. I saw it as an industry separate from our core tourism-based industry; having another industry like cannabis is really a cool thing.

I was brought on right after we won the license. They wanted some help navigating all of the regulatory and legal aspects of this industry, which is a lot. So, that is what I was brought on for and I’ve been here ever since. It’s been a fun ride.

NP: What about you, TY?

TC: Well, my tutu [Editor’s note: a Hawaiian term for a grandparent used to grow cannabis out in Hawai‘i Kai in Honolulu County]. She used to tell me she used to grow these plants for her migraines, and she would share it with her neighbors who also somehow were all afflicted by migraines out in Hawai‘i Kai.

[When I was living on the mainland,] I always looked for ways to return to Hawai‘i, and cannabis was really one of those avenues. As you mentioned, there’s not a lot of industry here in Hawai‘i, with tourism being the greatest and largest sector that brings some money in. And I’m also an attorney, and so there really is not much outside of wheels and trucks and real estate law here in Hawai‘i to really do anything with. When I heard about the dispensary licenses being offered up, I really looked into forming the team and drafting that application to come back to Hawai‘i.

NP: We live in a very unique geographical area. What have been the challenges and opportunities of operating in that environment?

TC: Hawai‘i is one of the most remote communities in the world. And so, that definitely, I think, is the greatest challenge. People who may bring some good cannabis background or experience to Aloha, they end up leaving in two to three years. It’s a nice stint for them to be here and surf and enjoy the weather and the ocean, but they sometimes feel that they can never get ahead or save enough to really settle down and enjoy a good lifestyle. [Editor’s note: A 2020 University of Hawai‘i review of Bureau of Economic Analysis data revealed that rents in Hawai‘i are more than 50% higher than the U.S. national average and cost of goods is 11% above the national average.]

Coming with that remoteness also is shipping costs. We have such high shipping costs to get nutrient feeds and even pots and just any type of growing infrastructure to Hawai‘i. And then, because we’re in the cannabis industry, we do use specialized equipment that’s just not readily available here in Hawai‘i.

But on the good side, we have a great photo period here in Hawai‘i, especially Big Island, you guys are getting lots and lots of UV there, and it’s a 12-12 photoperiod. So it’s great for the plant, and we don’t have to worry about frost and any type of issues like that. But that also means the pests and insects really have no frost to kill off their growth cycle. So, we do see a lot of different styles of pests and aphids that could affect plant growth.

cleanee_final_fmt.png?auto=format%2Ccompress&fit=max&q=70&w=400)

TC: How do you address some of those issues that are further exacerbated on the Big Island, such as the remoteness, the staffing and availability of just about anything?

NP: It really comes down to a lot of coordination and flexibility throughout the entire team. Being in a vertical market that we are, we have to do everything: growing, curing, manufacturing, packaging, delivering, and ultimately sales. Every piece of that supply chain has to work in unison, which isn’t always the reality. I think growing with the sun and the seasons [in greenhouses] means that every year is different. Plants don’t always adhere to your strict production schedules. Sometimes they decide they need another week to grow, and that’s something that we always have to be flexible with. We got really lucky with our team, it’s very small and nimble. We’re a startup, so we are not flush with cash, and we got to make do with what we have. And it really takes everybody doing their job well and being able to make adjustments on the fly to be successful.

NP: What are some of your thoughts on operating in this vertical market structure?

TC: I think the legislators and regulators were correct at the time when they designed the program and they looked at verticals such as Florida as a system to follow. And verticals inherently make it much simpler and easier for the regulators to track product and track the licensees and make sure that there’s no diversion or illicit market input into the program.

It does create, of course, huge inefficiencies and challenges for the operators. Instead of focusing on core competencies, we’re forced to do everything. Although now that five years have passed, you’re starting to see among the eight licenses some kind of core competencies just emerging really from the teams that they’ve been able to pull together and the IP and technology that these teams are leveraging.

I don’t know if it’s the right type of model going forward in the program. There are major challenges when it comes to supply and retail. You also have very high HR costs. Unlike the mainland where a number of smaller aspects of a cultivation operation can be subcontracted out, such as trimming and packaging, we don’t have roving groups that are able to provide that type of support. What it means is that you have to carry this HR burden for the entire year and really find and plan out your production schedule.

TC: And with the vertical [program, Hawai‘i has] eight licenses: there’s two on Big Island, two on Maui, three on O’ahu and one on Kaua’i. What do you think about this competition? What’s your relationship with the other licensee on the Big Island?

NP: The geographical isolation of each island makes it so we really don’t view it as this super competitive landscape. Even on our island, both of the licensees here, we both have very different, unique strategies and business practices. There’s room for both of us. It ultimately results in greater choice for the patient, so I don’t view it as this strict competition. Especially with those on the other islands. I have some pretty great relationships with the other licensees. It feels collegial. I feel there’s a general desire to help each other. It’s the adage: “a rising tide raises all ships.” That’s how we view it.

TC: Do you feel there’s any competition with the large-scale prohibition [illicit] market? It’s no secret that both Maui and Big Island have massive prohibition green market growth that are there.

NP: Yeah, definitely. The geography makes it so that cannabis really thrives here. There’s a very strong relationship, going back to ancient times, of a plant-based medicine culture. The idea of being able to grow your own medicine is deeply rooted in our native culture here and is not something we’re looking to take away. It’s tricky because the legal cannabis market that we’re operating in puts a lot of those traditional mentalities at odds with each other.

We strongly believe that the medicines people are purchasing need to be tested so that they know that there’s no pesticides, heavy metals or molds present. That gets down to a health and safety priority. At the same time, it would really be a shame to lose the unique genetics and these decades-old growing techniques that have been carefully developed and passed on over the last century or so by local growers. We need to find a way to bring these local growers into the fold of the legal market, and it should be a priority of our industry to really preserve these distinctions that make Hawai‘i one of those cannabis meccas of the world.

NP: What’s it like operating a cannabis business in a place like O‘ahu where tourism takes up such a large part of the economy?

TC: O‘ahu is known as the gathering place. It’s the largest, most populous of all the islands. We see over 6 million visitors a year, so our business is inextricably linked to tourism. Many of our patients are workers within the tourism industry or are in businesses that are affected by tourism.

During the COVID-19 pandemic, we’ve really seen that hurt among all our patients and among the local community. Aloha [is] a locally owned company, and so we really focus on trying to help the local people who have faced financial hardship. We’ve developed some programs to help people who are low income or may have lost their jobs because the pandemic or maybe are on unemployment at this current time.

But, of course, tourism is always there, and it’s no surprise that Aloha has chosen to open three retail locations that are close to tourism centers. South King Street, our first location is maybe two blocks from Ala Moana shopping mall, which is the largest outdoor shopping mall in the U.S. And then our second location, the Waikiki site, is right in the middle of the Waikiki business district, which is where the tourists who come to visit O‘ahu pretty much all are located. And then our third location at the airport is right by the car rental pickup areas. And it really is to make it easier for tourists and visitors to be able to access cannabis when they do come.

TC: I want to talk about extraction a little bit. I know that Hawaiian Ethos has chosen to go solventless in your extraction methods. Can you tell me why and how it fits within your product mix?

NP: We made the choice pretty early on to go with ice water hash extraction. The big thought around that was just, “how do we preserve the natural plant and all of its compounds?” For us, we thought that the best way to preserve those natural compounds and keep the products as close to nature as possible was through that solventless extraction process. It’s a rewarding process, but it’s not without its challenges. One of the benefits is that we don’t have to import solvents. Water is a natural resource here, and it’s a safe process to work with so, from a compliance perspective, it definitely puts my mind at ease in that regard.

On the opposite side, it’s a very labor-intensive process requiring a hands-on approach throughout the whole thing. It truly becomes this craft product, and that’s one of the things that really distinguishes our products and makes them really unique.

NP: You guys have chosen to go with hydrocarbon extraction. What have you’ve seen with that and what was the thought process behind the decision to go that route?

TC: At Aloha, we’ve moved through almost every extraction method. Our goal from the very beginning was to be a very strong manufactured product maker, so we have six full-time employees in the manufacturing side with support. We started off with ethanol extraction, and then we quickly moved over to CO2, and now we have pentane as well, so we do a number of types of extraction depending on the type of product that we’re trying to pull. Throughout the entire process, we are very terpene focused. Even though we do use solvents, we have cold traps and vacuum systems throughout the entire process to recover all terpenes that could be lost along the way. It’s very important for us to reintroduce that into the final end product.

TC: How have you addressed the restrictions that we have as licensees for marketing and advertising and educating patients?

NP: Because of those limitations placed on advertising, we haven’t really taken any huge steps out into that public space.

Early on, we did a bunch of small educational community events that highlighted our different growing practices and unique products and things like that. Once the pandemic hit, that really put an end to those outreach events, and we really just reverted to putting our efforts into the products themselves and educating people on the direct patient-facing fronts that we do have in the store.

We put a lot of internal company time into educating our staff so that when we speak to patients, it’s really coming from a place of science and knowledge and, at the same time, acknowledging that there’s still things that we don’t know about the plant.

NP: Same question to you TY, how are you guys dealing with this limitation? I know you really put yourself out there in terms of community engagement, and it’s one of the models that we’ve been looking at and admired.

TC: Every quarter, we select a local charity that’s willing to accept cannabis-donated funds, and we do a lot of sponsorships. We try to help out whenever we can when we are approached. And like you said, with the restrictions on traditional media, we try to use social media as much as we can, and we rely on the Coconut Wireless [Editor’s note: a Hawaiian spin on word-of-mouth marketing]to spread that message.]

And similar to Ethos, we are very focused on the customer service experience. We have a dedicated patient outreach coordinator who reaches out to every single new patient that comes into our stores and registers with us after their first visit. And it’s available for them to discuss working out a medication schedule or understanding what products are available for them to use that might help alleviate their specific symptoms or conditions.

NP: How has your company tackled the issue of sustainability in the cannabis industry?

TC: We live on an island. All our shores surround us, the water that’s around us is very important to us. Not only does it provide habitat to the local fish that we consume, it’s also the playground for our children and for ourselves. So, we’ve got to be really careful not to upset that balance and that ecosystem.

Aloha pursued the hybrid greenhouse model for cultivation. We have a sealed, indoor-style grow, which provided a platform for the nursery and genetics as we went down that path of finding the right strains. And then we moved into about 20,000 square feet of hybridized greenhouse with that kind of opaque, transparent roof. And I know Ethos is similar, they have a similar cultivation methodology. It’s really important to us to try to really not be such a high carbon emitter.

Water is also super important to us, and we have water conservation efforts on our property. We try to limit the amount of any type of runoff or from the plant itself that’s going to be going to the environment and really just try to minimize the amount of inputs that we can put into the plant.

TC: How about you guys at Ethos?

NP: Sustainability has been one of the pillars of our company from the start. We were one of the first licensees to go with completely compostable packaging. That’s a difficult thing to do while still meeting all of the child safety restrictions and all the regulations that kind of come along with packaging. It’s tough to source.

Because we’re sun-grown [in greenhouse], we have been able to dramatically reduce the amount of energy required to grow our crop, which is a huge thing in Hawai‘i, given the pretty outrageous energy costs here, which are some of the highest in the nation. Hopefully by the end of this year, we’ll have completed our solar array at our farm, pushing us to carbon negative for cultivation.

TC: I have to say that, at Aloha, we were inspired when I came to visit your site and see your packaging. And so we recently revamped our entire packaging line to ocean-reclaimed plastics and recyclable paper packaging, as well.

We’ve also been able to reduce our power usage by 30% over the past year while still yielding the same amount, if not more, than we did a year ago. And that just comes with better understanding of the plant and how to optimize your electrical usage during that period.

We also invested in a solar project set to kick off at the end of this year that will take us 100% off-grid, which is something that we’ve always wanted to move towards.

TC: What do you think the odds are for federal legalization? And what do you think it’s going to do for Ethos and really for cannabis in general?

NP: I think it’s definitely positive. It’s still going to be a little while before we see legalization at a federal level. With the pandemic going on, there are a lot of national priorities that come before cannabis legalization. I’m most optimistic for banking reform. I think that’s something that we could see probably sooner than outright legalization and de-scheduling.

In terms of what it would mean for us and our industry, it really opens up our market to a much larger patient base who might not currently fall under the current qualifying conditions. I think a lot of people see cannabis as preventative medicine, something that you take before the condition really presents itself, and those people right now are outside of the industry looking in.

NP: What about you, TY?

TC: Yeah, I agree. I am hopeful, but like you said, I wouldn’t bet on federal legalization happening soon. There are many issues that the country is facing before legalization. I think if it does come, it would expand our market, allow us greater access to capital for us to grow, and for us to have greater reach to show people what kind of positive effects are available—things my tutu knew 60 years ago.