1. How far along are new regulations, as they relate to cannabis?

This is a question we get daily. Water regulation is embedded in the legal language for new permits, but the actual details remain vague. This was intentional, as it gives every municipality authority to construct their own rules. Always assume if there are any conflicts, the strictest rules will win out. Therefore, it is important to understand water-management options as thoroughly as possible when in the site-selection stage, so equipment needs and overall cost to meet required standards can be factored in early.

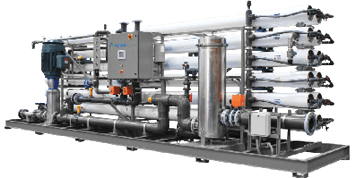

2. Why is reverse osmosis still the most cost- and energy-efficient option?

Reverse osmosis (RO) technology has been around for a long time, but what people may not know is how much more efficient these machines have become. We can get 85-percent overall pure water recovery out of what would normally go down the drain as waste water, at a very low energy expense. There are other options, such as distillation, which can yield a higher recovery rate, but the price and energy requirement to do that is much, much greater.

3. There seems to be no escape from some amount of waste. What are the factors a new facility must deal with, as they pertain to new regulations coming online?

Every site will have its unique problems to deal with when it comes to managing waste water. In some cases, trucking out effluent (wastewater) would be a viable option; in others, wastewater could be used to irrigate other crops, or sent to evaporative ponds designed specifically to dissipate nitrates. The most water is conserved by capturing everything, RO waste to HVAC condensate, and continually recycling through several filter stages until the “sludge” is sent to an evaporator.

4. What happens to the remaining water?

It is completely separated from solid contaminants, which are disposed of easily at that point. Our Automated Reclamation Condensate System (ARCS) goes the extra mile to push toward zero waste, which looks very favorable when in the process of obtaining a permit.

5. What should you search for in a water-filtration provider?

You’ll want to look for a company with experience. We’re growers, and we’ve spent the past decade and a half solving every water/cannabis problem imaginable, with many thousands of case studies under our belts. We treat every situation as a specific set of issues, with the goal to scale premium-quality product to a commercial level. Also, because no two operations are alike, every system should be custom built.