1. How can the injector system help me monitor pH along with my fertilizer ratios?

The injector system provides a means of ensuring that a user-adjustable metered amount of pH controller and fertilizer are dosed into the water batched for irrigation. Think of it as a batched proportional mixing system.

The addition of an optional BlueLab Pro Controller allows the user to dose the batch tank via pH and EC probes, allowing for much faster EC and pH set point adjustments to be made compared to the additional time needed to adjust a batch proportional mixing system.

2. How does the injector system work?

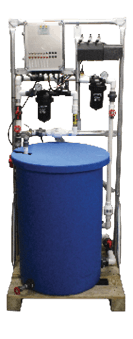

The injector proportionally adds nutrient and pH adjuster to a 50-gallon batch tank via electronically controlled bellows pumps.

Float sensors in the batch tank detect when the water level is lowered after an irrigation event. This triggers the opening of a solenoid, filling the batch tank with source water. The flow rate of the source water into the batch tank is controlled by a user-set butterfly valve. As water fills the batch tank, it triggers a flow sensor. This flow sensor in turn activates the bellows pumps, dosing the batch tank with fertilizer and pH controller pulled from concentrated stock tanks.

Safety features include a low-level float sensor that will shut off the injector pump if the batch tank fails to fill. It also has a pressure switch downstream of the injector pump, which will trigger an alarm state if the pressure dips below the manufacturer set level. This alarm generally indicates a clogged filter, air-locked pump or other issue with the injector sending water out to the crop, and the alarm can be paired easily with an auto dialer or greenhouse alarm device.

3. What is the cost/benefit analysis for an injector system?

The injection system easily pays for itself after a few uses. For example, if you are paying labor at $15/hour and it takes five hours to hand-water a room, it only takes a little over nine weeks to pay for the injection system in labor alone, assuming a seven-day watering schedule.

4. What is involved with unit installation?

The unit comes assembled and pretested on a pallet ready for placement in the growing area. All that is needed to finish installation is a power supply, wiring to any watering zone solenoids, nutrient stock tanks and connections for inlet and outlet water.

5. How will an injector system integrate into my current water and nutrient delivery methods?

If you are already using a drip irrigation system, the injector will simply be installed between your solenoid zone manifold and your source water. If using a reverse osmosis system or similar filtration, the injector will be installed downstream of this.