About 400 years ago, Dutch settlers claimed as their own New Netherland, parts of what Americans now call the Mid-Atlantic and New England. One of their New Netherland settlements, Fort Nassau, preceded Albany, N.Y., and they allegedly purchased Manhattan Island in modern-day New York City from the Lenape people. They named the southern part of the island New Amsterdam.

Descendants of these settlers born generations later, such as Theodore and Franklin Roosevelt, presided over the country’s highest office.

Cornelius Vanderbilt, the railroad magnate and major donor to and namesake of Vanderbilt University in Nashville, Tenn., hailed from a Dutch family (from De Bilt, Netherlands, hence the name). So did poet Walt Whitman’s mother, who he memorialized in “Leaves of Grass” as “the ideal woman, practical, spiritual, of all of earth, life, love, to me the best.”

This just scratches the surface of how Dutch immigrants played a key role in developing both colonial America and the modern-day U.S.

Members of another Dutch family, Aart and Cora Van Wingerden, immigrated to the U.S. in the 1940s, and their family has, in many ways, developed a niche segment of the country’s economy—the ornamental greenhouse industry.

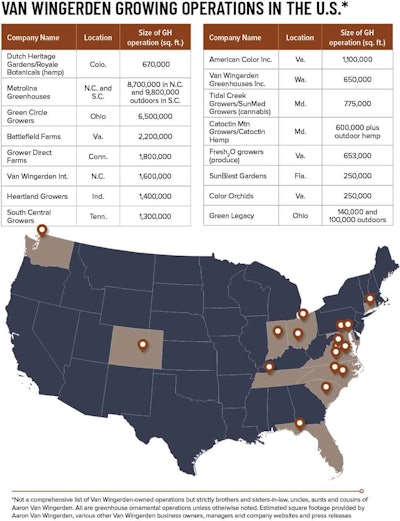

Ornamental plant-focused greenhouse production companies owned by Van Wingerden family members, such as Metrolina Greenhouses in Huntersville, N.C., and Green Circle Growers in Oberlin, Ohio, have become synonymous with innovation and efficiency through the use of technologies like robotic transplanters and advanced environmental controls, and today account for more than 30 million square feet of U.S. greenhouse space.

Now, Van Wingerden family members are diving into hemp production using many of the same production methods.

Aaron Van Wingerden, one of Aart and Cora’s grandchildren, founded Dutch Heritage Gardens with his wife, Rozalia, in 2006 in Larkspur, Colo. In 2014, after eight years running the greenhouse operation, where his team grows annuals, perennials, vegetables and more, Aaron expanded into the state’s adult-use cannabis market. Then in 2017, he left that realm and transitioned into hemp under a new business name, Royale Botanicals—all while continuing Dutch Heritage Gardens’ ornamental operations.

Aaron and his team built the entire greenhouse facility for Dutch Heritage Gardens and Royale Botanicals to 16 acres, including 3 acres for production of hemp mother stock, clones, and CBD and cannabigerol (CBG) smokable flower, along with a 1-acre hemp R&D field outdoors. He’s now pulling from his ornamental industry connections to develop a nationwide hemp clone-to-grower pipeline (including a recent partnership with Dümmen Orange, a century-old global ornamental plant breeder and developer) while working toward a launch of various cannabinoid-based end products.

A Love for Growing

In the Netherlands in the 1930s and 1940s, Aaron’s grandfather Aart grew vegetables and potted crops and sold them to farmers markets. His talents and insights helped him advance his career when he settled in America, Aaron says.

“He was very well-known for having a green thumb and being very innovative,” Aaron adds. “He helped pioneer a lot of different innovations in the greenhouse world as far as structures go, airflow, different environmental controls. He was always thinking of how he can grow a plant better and faster.”

Aaron shares that all of Aart and Cora’s 16 children entered the greenhouse industry. “The boys started their own [companies], and the girls married somebody that was in the greenhouse business themselves,” he says.

“[Aart] did a lot for the industry throughout his life and passed that love on to his kids,” Aaron says. “I know my father and all of my uncles and aunts worked in the greenhouse from a very young age during the summer season or on the weekends outside of school. My grandfather was very adamant about instilling a hard work ethic in all of his kids—and then the love for greenhouse growing and management developed in all of them.

“Me, being a third generation in it—it developed in me, as well. My dad took a very similar stance with me.”

Aaron’s dad, Arie, and his mom, Lynn, were former ornamental greenhouse owners, and Arie now owns greenhouse equipment supplier Cherry Creek Systems. Aaron has 11 blood-related siblings, including fellow greenhouse owners Jake (who grows cannabis and ornamentals) and Caleb (who grows ornamentals), and his parents adopted 10 children. He grew up in Pennsylvania and moved out to Colorado with his family as a teenager.

“I worked in the greenhouse every summer, five days a week, and on the weekends when I wasn’t in school,” he says. “I developed a love for greenhouse growing … at a very early age, and I knew it was something I wanted to do with my career.”

Clone and Smokable Flower Production

Since Aaron and Dutch Heritage Gardens launched the Royale Botanicals hemp division in 2017, the company has increased its hemp clone output by 100-fold. “We started with 50,000 clones in 2017,” Aaron says. “Last year, we grew 5 million.”

There’s a seasonality to the clone production, says Sam Burney, Royale Botanicals’ national sales manager. The clones, grown alongside Dutch Heritage Gardens’ ornamental plants, completely fill the greenhouse in the spring and early summer, Burney explains, and the business continues to grow a smaller number of clones throughout much of the year for greenhouse and indoor producers who grow to full term.

Smokable flower production also accounts for a large portion of Royale Botanicals’ business, Aaron says, comprising roughly 25% of the business as of mid-October.

Royale Botanicals uses many of the same technologies that Dutch Heritage employs for ornamentals, including irrigation booms (a type of overhead irrigation that moves over the plants), supplemental lighting and light-deprivation curtains.

“We have a few robotic transplanters, which really speed things up and make it more efficient, as well as some of the tech that we have to increase our humidity and rooting success, [which] has really been a gamechanger …,” Burney says of humidification equipment that Royale Botanicals has incorporated into its environmental controls system.

Aaron says there are both similarities and differences between growing ornamentals and growing hemp.

Hemp is an obligate short-day plant, he says. This means it only flowers when the photoperiod, or the amount of light the plant receives in a day, is below a certain amount, which is roughly around 13 hours of light or less.

So, growing hemp is in some ways similar, he says, to two other obligate short-day plants Dutch Heritage Gardens grows: hardy chrysanthemums and poinsettias.

Supplemental lighting and light deprivation allow greenhouse growers to achieve optimal conditions for all three crops to flower, he says, which is why he uses light-deprivation curtains and lights (both LEDs and high-pressure sodium, or HPS, lights). Greenhouses often need to provide additional lighting to support vegetative growth, then use light-deprivation curtains to reduce the photoperiod.

The lighting requirements for hemp depend on the cultivar, Aaron says, but change is a constant. The day length will need to be reduced to flip the plant from its vegetative growing cycle into its flowering cycle, whether through natural or artificial means.“We have light-deprivation curtains here in the greenhouse already installed for our mums and poinsettia crops,” Aaron says. “So, we can just utilize that equipment … to time out hemp crops in the summertime. We’re tricking the plant—[because] obviously it’s shorter day length than it is [naturally] here in June and July—to get crop cycles to produce flower on a weekly basis.”

When the smokable hemp is in the flowering stage, Aaron and his team also run lights during the day. This is to increase yield, which is of benefit to certain vegetable crops such as tomatoes and cucumbers, but isn’t a concern with ornamental flowers.

“A red petunia—once it’s red, I can’t get it any better red and ready for sale, that’s its value. I can’t get it any better red to increase the value of that particular plant,” he says. “With hemp, you’re trying to yield more. So, the more light that you can put on the plant, the more micromoles of light it absorbs and the more energy it puts off, which increases your yield and therefore increases the plant’s value.”

Pest control also differs between ornamental and hemp production because, as most hemp growers know, fewer control products are registered for use on hemp, Aaron says.

He says that in his experience, neem oil and other organic products that are approved to use on hemp have been less successful at controlling pests than synthetic products would be. “One of the harder things … with hemp—because it’s a food product and it’s new and people consume it—is the limitations of [chemicals] that we can apply to the plant,” he says. “There are a lot of things that you can apply to vegetables, herbs, other edible crops that we grow that are not allowed to be applied to hemp or marijuana, as of yet.”

The Dümmen Orange Partnership

Between about April 15 and July 1, the business largely focuses on the production and sale of clones, which account for about 75% of Royale Botanicals’ revenue, to service outdoor hemp growers. But because greenhouse and indoor hemp growers have multiple growing cycles, Royale Botanicals also produces and sells clones to those growers throughout the year. In addition, the company produces much of its smokable flower between about July 1 each year and the following spring, aside from a winter lull.

In April 2021, the company announced that it is expanding its hemp network through a partnership with global ornamental plant breeder Dümmen Orange and the breeder’s growing-media-focused Quick Plug division.

The Royale Botanicals and Quick Plug partnership will allow the companies to work together to improve genetics while increasing clone distribution, Jamie Chittum, Quick Plug North America’s director of business, told Hemp Grower in May.

The partners have shipped clones to growers in the U.S., the Netherlands and Switzerland, Aaron said then.

The burgeoning hemp market can’t be ignored, Chittum said at the time, adding: “Dümmen [Orange] has been looking at this for a while and decided that this would be a good time … [to] pilot the approach and then work with professional partners to make sure that we were part of a very sophisticated, professional supply chain.”

RELATED: A Glimpse Into the Royale Botanicals, Quick Plug Hemp Clone Partnership

The Royale Botanicals Brand Launch

This winter, Royale Botanicals will launch its own brand of products, including smokable flower, pre-rolls, tinctures—or “elixirs,” as the company will call them—other consumable products and topicals under the Royale Botanicals name, Burney says. It will sell these products online and to smoke, vape and CBD shops, as well as possibly to Colorado-licensed cannabis dispensaries.

Burney points out that Royale Botanicals contracts with other hemp growers in southern Colorado and Kentucky to produce biomass to sell to extractors. He and Aaron say they plan to continue with this approach rather than adding extraction in-house.

“I’m a big proponent of staying in your lane, and I know how to grow plants really, really well,” Aaron says. “I’m not a chemist. I’m not an extractor. That’s a lot of CapEx expense, and there’s really, really good [extraction businesses] out there that we work with currently.”

There could be a place for more low-THC products in dispensaries, Burney says, adding that smokable hemp flower presents a distinct opportunity.

“I think there’s an underserved market of future consumers out there who maybe haven’t experienced cannabis at all—especially smoking it—and will enjoy smoking cannabis that is not high in THC,” Burney says. “We see a big opportunity in that, and it’s a path less followed, and a little bit more [of a] difficult marketing strategy—introducing new consumers to smokable cannabis products that are rich in CBD or other cannabinoids and low in THC.”

“There’s plenty of people out there that want the benefits of cannabis but don’t want to be stoned,” Aaron says. “And that’s where CBD flower comes in.”

More Work to Do

When looking to the hemp industry’s future, Aaron quotes a mentor and friend, Dr. Royal Heins, professor emeritus in Michigan State University’s Department of Horticulture.

“One of his sayings is, ‘In God I trust, and all others: bring data,’” Aaron shares, adding that more data will be required for the industry to make the most of cannabinoid hemp and its various compounds.

“I think we’re just scratching the surface on the possibilities of the plant itself and all the CBN [cannabinol], CBC [cannabichromene], CBD and all the different letters, if you will, that come with the plant,” he says.

Aaron says he expects the industry to move past pushing a “one-size-fits-all” approach to cannabinoid consumption, where companies simply recommend consumers take more of a given product for various ailments. More data is needed so companies can formulate hemp-based medicines that effectively treat certain conditions, like how customers trust over-the-counter drugs to control headaches and migraines.

“I think once that comes about with CBD, the industry will level off [from these] highs and lows that [we’ve seen] the last couple of years, and the professionals that can deliver those end products consistently will be the ones that survive and thrive.”