“I don’t understand! How can this batch fail when previously tested cultivars all pass?”

“How can we have pesticides in our extract? We don’t spray pesticides on our plants!”

“How is there a presence of metals in our formulas? This doesn’t make any sense at all!”

It is unfortunate, but these are valid statements that have been made by many people working at cannabis operations. Contamination, potency reduction and other concerns can arise during the cultivation, processing and manufacturing of infused- cannabis products.

It’s no secret that problems arise in production environments; however, what delineates a successful cannabis producer from one in constant remediation is understanding analytical testing and its vital role in shedding light on the health and quality of your operation.

The statements above can be alarming to members of the leadership team who do not come from a scientific background. The cannabis industry has done a great job attracting talented people from diverse backgrounds in horticulture, consumer packaged goods and general manufacturing to bring a collective knowledge base to the table. Yet, when your industry is based on the foundation of biological and chemical principles, a member of the executive leadership team needs to be a scientist who can use his or her experience to discover the right analytical methods to monitor spikes in concentration levels of specific contaminants, propose solutions to mitigate harm to production and more. In addition, this person needs to help answer certain operational questions such as: Are my parameters sufficient for optimal extraction? Does quality remain when the extraction process is scaled up? Are we appropriately tracking all process data to analyze yields and run times to optimize production?

Century-Old Testing Methods (With Enhancements)

Testing laboratories in the cannabis industry use various analytical methods adopted from the environmental, pharmaceutical and petrochemical industries. The instrumentation used to quantify cannabinoids, identify contaminants and collect qualitative data is not new-found, either. Russian botanist Mikhail Tswett first developed chromatography techniques in 1903, using a column of calcium carbonate to produce a colorful separation of plant pigments.

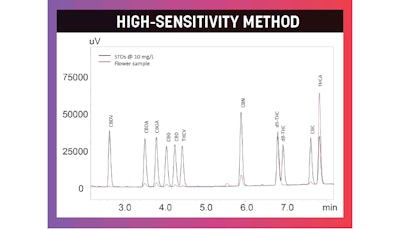

Chromatography has since developed into an invaluable laboratory tool for the separation and identification of compounds. High-Performance Liquid Chromatography (HPLC) is the separative vehicle equipped with either an Ultra-Violet/Visible (UV/VIS) detector or Diode Array Detector (DAD) to properly quantify phytocannabinoids using their individual fluorescent values. The cannabis plant produces more than 150 known cannabinoids. Hence, without sophisticated instrumentation, analytical techniques and scientific competency, qualitatively separating the compounds and quantifying the ones of interest would not be possible. In cannabis potency analysis, 11 compounds are of interest, with cannabidiol (CBD) and tetrahydrocannabinol (?9-THC) being the most popular to current producers.

Data on potency across multiple harvests, cultivar types, growing techniques, etc., is not readily available; therefore, it would behoove cannabis producers to archive all potency analyses performed in-house and chart the data to get an accurate read on the business’s processes and performance. This would provide a database to refer to when making predictions on plant performance and system health, as well as give insight into the feedstock being used for further processing activities. You could easily predict the potency of your crude extract using this data archive and performing a quick calculation (e.g., percent of oil created from volume of material) based upon the extraction technology metrics (e.g., pressure, temperature and solvent flow rate). This arsenal of data also will serve you well in validating the third-party testing lab’s analytical results used to approve your product for sale.

Contamination in Cannabis

Contaminants are an ongoing problem that plagues industries working with agricultural feedstock, botanical extracts and metal machinery. In the cannabis industry, laboratories monitor the amounts of pesticides, heavy metals, micro biologicals and mycotoxins present in representative batch samples. These contaminants can be introduced into your processes in a multitude of ways and can be detected using various techniques and instrumentation.

Pesticides: Pesticides can be introduced at different stages of your operation, including in raw materials (the ingredients imported for infusions as well as biomass used for active pharmaceutical ingredient (API) extraction). Pesticide contamination of raw materials can occur at the third-party vendor’s facility due to pest management procedures or during transport of the materials to your facility. Many markets have lists of pesticides approved (by state agriculture or other departments) for use on cannabis, as well as allowable pesticide residue limits for products sold to consumers.

This does not pose much of a threat for product sold as retail flower; however, if the flower will be used as raw material for processing, potential concentration needs to be considered. Concentration in chemistry is defined as the “amount of solute per amount of solution or solvent,” according to the University of Texas. A solute is a solid, liquid or gas substance dissolved by a solvent to create a solution. The process of extracting cannabinoids from the plant material is, in chemical terms, a concentration step, regardless of the solvent used. If trace amounts of a pesticide are present in the flower that is transformed into oil for infusion, processors risk concentrating the contaminant beyond allowable limits.

Pesticides are generally quantified in cannabis plant material and extracts by using liquid chromatography with tandem mass spectrometry (LC-MS/MS) technology. Compound separation occurs using chromatographic techniques, and those compounds are then detected by a triple-quadrupole mass spectrometer, which allows for higher sensitivity to detect compounds at very low limits. This technique is commonly used to quantify pesticide concentration in various flower, extracted oils and infused products. When interpreting these data reports, it is important to pay attention to the actual concentrations of each analyte versus just a PASS/FAIL. Investigating further is essential to understanding the parameters, processes and efficiencies. You have to look deeper into the actual concentration levels of analytes/contaminants in your samples to notice any compounding trends leading you to a failed test batch in the near future, understand the concentrating effect of processing cannabis flower into oils and to ensure consistency in the process and product.

Heavy Metals: Heavy metals commonly screened in cannabis plant material and extracts are lead (Pb), cadmium (Cd), chromium (Cr), arsenic (As) and mercury (Hg) to name a few. These metals naturally occur in soils and rocks. They can also be found in aquatic systems from natural occurrences, like volcanic eruptions, and human activities, such as mining.

This means the soil source used to cultivate the plants and the water used for irrigation could already contain significant levels of metal. Applying the concentration principle, it is essential to monitor the soil and water closely to ensure there will be no issues in downstream processes. In addition to cannabis testing facilities, environmental laboratories can use several reliable methods to determine the levels of metal in sources. Metals are analyzed through Inductively Coupled Plasma and Mass Spectrometry (ICP-MS).

Microbials: Micro biological organisms (or microbials) can destroy crops during early cultivation stages. They can also lie dormant in the plant until conditions are just right and haunt you well beyond harvest. Microbial tests include total count tests that target large microbial groups such as: aerobic bacteria, yeast, mold, and coliforms (present in animal and human digestive tracts, as well as in plants and soil). Traditional culture-based plating methods are typically used to qualitatively screen for microbes. Screening can also be done using DNA-based methods. Mycotoxins (toxic secondary metabolites produced by fungal organisms that can cause disease and death in animals) can be detected using LC-MS/MS.

Typically, if there is a microbial issue in the plant material, further processing can be the answer to soothe some of the financial impact to an operation. For instance, if botrytis is discovered after harvesting flower, processing through supercritical CO2 extraction will remediate the microbes, making it safe to infuse and for human consumption. However, this does not apply to mycotoxin-producing pests, as those toxins would be concentrated into the cannabis oil. Supercritical parameters of CO2 are defined as temperatures above 31 degrees Celsius (88 degrees Fahrenheit) and pressures above 74 bar (1070 psi). When microbes are present in supercritical fluid environments for prolonged periods of time, sterilization occurs due to cytoplasmic acidification, membrane destabilization and overall physical cell rupture. In layman’s terms, the microbes freak out being present in solution and explode.

This information will enable processors to competently mitigate microbial issues in their operations. Having the capacity and flexibility to navigate through operational issues caused by scientific factors is crucial, and this can be done by utilizing a diverse team of scientists to attack problems.

In conclusion, businesses can successfully interpret data associated with the intricacies of cultivating and manufacturing cannabis products by:

- Understanding technology and methods needed to operate an internal, quality lab to support production.

- Monitoring certificates of analysis (COAs), scrutinizing the individual analyte concentrations rather than just looking at PASS/FAIL.

- Trusting, but verifying the accuracy of third-party testing labs utilizing your own in-house laboratory methods and historical data.