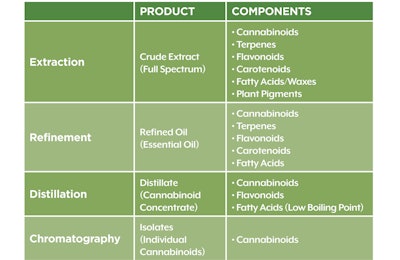

Cannabis extraction and refinement create different raw materials for formulation. They are critical processes that separate cannabis extracts into their component molecules. Cannabinoid distillation is a particularly complex stage of the extraction and refinement process that involves a nuanced interplay among component boiling points, heat and vacuum.

Here are some tips and tricks producers can use in their distillation protocols to optimize their results.

1. Aim for highly refined and clean material.

Limit the number of substances that interact during the distillation process and components that can negatively affect the performance of the equipment. For example, certain fatty acids have boiling points near cannabinoids and will often polymerize, which diminishes product purity and increases system maintenance. Also, components of the refinement process (i.e., clarifying agents) can cause isomerization during distillation. To mitigate this, refine extracts prior to distillation. Refinement processes include winterization, clarification and scrubbing filtration.

2. Fully decarboxylate and degas the material.

A simple way to increase the throughput of the distillation process is to decarboxylate and degas the cannabis extract before distillation. Decarboxylation and degassing are the processes of converting the acid form cannabinoids to the neutral forms and removing volatiles, respectively, by applying heat and agitation. By undertaking those two processes, the vacuum operates under reduced load and more cannabinoids are distilled per unit time.

3. Use a well-designed vacuum system.

The atmospheric boiling points of cannabinoids are not known to any degree of certainty because these heavy molecules tend to degrade before they boil. However, by removing atmosphere, the cannabinoids can be encouraged to boil at a lower temperature. Their boiling points under vacuum (i.e., 5x10-3 Torr)—as documented by Adams et al. in 1941 and Gaoni & Mechoulam in 1964—are between 155 and 160 degrees Celsius. That’s why it’s important to have a substantial vacuum system to reduce the heat required to vaporize cannabinoids and minimize the risk of degradation. An ideal vacuum system for this application is a dual-stage rotary-vane pump designed to pull to 1x10-4 Torr with a diffusion pump to increase the depth and stability of the vacuum under load. It’s also important to correctly size the tubing and seal the connectors.

4. Maintain short heated-surface contact.

Heat can degrade or isomerize cannabinoids. Use a system that can deliver heat to a thin layer of oil to minimize total heat exposure. Wiped film or centrifugal systems are ideal for this because the oil’s contact with heat is several seconds compared to several hours. Finally, stainless steel heating surfaces (i.e., still body or centrifugal plate) increase the efficiency of heat transfer and the throughput of the distillation process.