Editor's note: This article was previously published in the October 2019 issue of Cannabis Business Times.

Whether it’s extreme heat or bone-chilling cold spells, severe weather is always a potential issue for cultivators. Major weather events can wreak havoc on crops if cultivators aren’t prepared for the worst. Knowing how to properly manage heating, ventilation and air conditioning (HVAC) systems can make the difference between safely riding out the storm and a potential crop failure. Here are six tips cultivators should consider to prevent potential losses when extreme weather hits.

1. Know your local climate, and keep an eye on the weather forecast.

In Colorado, we are no strangers to rapid, sudden weather changes, and they are common in many other major markets, as well. Blazing hot summer days, spring and fall thunderstorms and winter snowfalls can lead to disaster if you’re not prepared. Check forecasts regularly so you know what to expect and when to expect it.

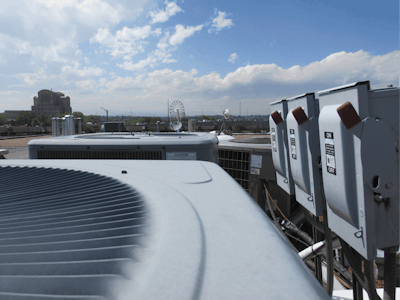

2. Winter is coming. Try capping off your intakes.

During winter, growers often completely cap off the intakes on the roof of their flower rooms. Pulling cold air from outside and pushing it into a hot flower room is a recipe for humidity spikes and dripping ducts. We pull the outside air into the veg room, let it warm up and then direct that warmer air from the veg room into the flower rooms.

3. Unusually hot weather? Consider regulating your air exchanges.

Car air conditioners often have a recirculate function that cools the cabin faster by continually chilling already-cooled air. You can apply the same idea to your grow. Instead of using energy to cool outside air, focus on maintaining the already-regulated inside air. When you do need fresh air, pull it at night when it’s coolest.

4. Don’t be afraid to run your rooms a little hot to take the load off your system.

HVAC units should not run at 100% all the time. Operating your system at full blast leads to frequent and costly breakdowns. You can reduce maintenance costs and system downtime by running your system more gently by reducing fan speed and thereby increasing temperature. And a little extra heat in the grow room isn’t always a bad thing. Cannabis can handle some heat, especially if you’re supplementing with CO2. Anything over 85 degrees Fahrenheit is a cause for concern. Ideally, I like to keep my rooms around 74, so that extra 11 degrees is the wiggle room. However, hot grow rooms can lead to flower problems, such as foxtailing and yellowing, so monitor the environment closely (see tip No. 5).

5. Familiarize yourself with the vapor pressure deficit (VPD).

VPD is the difference between the water pressure in the air and the water pressure within a saturated environment, when both are measured at the same temperature. This metric helps you track your plants’ comfort much more precisely than just temperature and humidity. If you’re running your grow rooms a little hot, tracking VPD will help you foresee any potential problems with your grow and address them before they happen.

6. Always have a contingency plan.

There’s no getting around it: Extreme weather puts a strain on cultivation systems and sometimes things go wrong. Power outages and broken parts happen. Consider installing a backup generator, and always maintain good relations with a reliable electrician and HVAC expert. Finally, consider running hypothetical emergency scenarios so you and your staff are fully prepared when extreme weather hits.