For the past five years, Cannabis Business Times’ exclusive research reports have focused on investigating and benchmarking various aspects of cultivation, from overall industry trends to lighting, nutrients and odor control. This year, for the first time, CBT conducted a study about what happens after harvest, examining cultivators’ drying, curing, trimming and other practices.

This research, conducted by third-party company Readex Research and made possible thanks to the generous support of Quest, provides a glimpse into how indoor, greenhouse and outdoor cultivators manage the post-harvest process. The “Special Report: Cannabis Post-Harvest” features data on temperatures and humidity levels growers like to maintain in drying and curing rooms and how long they dry and cure cannabis—benchmarks cultivators can compare to their own processes. Research participants also noted their top post-harvest challenges, the top three being hand trimming, curing and drying. Getting the environmental conditions, especially humidity, just right was another aspect cultivators said they struggle with.

Dr. Markus Roggen, Ph.D., founder and CEO of Complex Biotech Discovery Ventures, likens the cannabis drying process to roasting a Thanksgiving turkey—there are myriad options for dressings and a range of cooking times, but the goals are the same: Cook the turkey long enough so that it is safe while preserving moisture and flavor.

“Everyone makes their turkey differently, but there’s a rule—you need to get over 165 degrees F to not get salmonella,” says Roggen, who conducted research to determine drying and curing best practices while he was vice president of extraction for cannabis cultivation and extraction/formulation company OutCo. Like cannabis, “there are some hard numbers around which you will play.”

Cannabis moisture can and must be measured to prevent mold, Roggen says, and certain drying temperature and humidity ranges stymie bacterial growth while preserving terpenes.

“For drying room conditions, we found the optimal window is 60 to 74 degrees F and 40% to 60% humidity,” he says. “We found 10 to 14 days worked well for us to preserve terpenes but to free the room for the next harvest.”

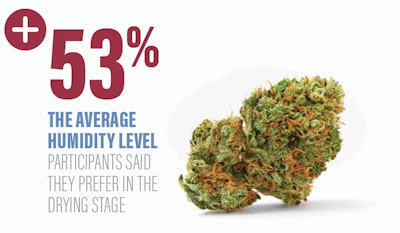

Looking at the research from the CBT study, cultivators appear to be in those optimal ranges—the average reported temperature in drying is 65 degrees F, while the average humidity level is 53%. Some cultivators said, as Roggen suggested, they like to “play,” preferring “variable” conditions for both temperature (7%) and humidity (11%).

Curing parameters can be more difficult to pinpoint, he says. He likens that stage to wine aging, and there are still many compounds that are important to cannabis flavor that the industry does not yet consider or fully understand, Roggen says.

“How do you define a good cure? Right now, a good cured cannabis bud is defined by the guy who smokes it and likes it,” he says. “The end product is still at the mercy of the consumer. Some people like red wine, some people like white. … There is still the sensory aspect that we have to consider.”

Although there are certain benchmarks and safe ranges to stay within, Roggen says it’s important to continue to explore variables in the post-harvest process and how best to optimize it for safety, efficiency and product quality.

“We should not be fearful to experiment, and we should not be content with the current status.”

As you navigate the research included in this report, perhaps it will spark opportunities to trial and explore in your own facility.