What Happens After Harvest?

While much time, effort and money are spent to create optimal growing conditions to produce the highest-quality cannabis during cultivation, as growers know, what happens after harvest is just as crucial. The drying and curing stages are perhaps the most challenging to get right, as the timing of various processes can depend on flower size and density, and vary by cultivar, too. Preserving terpenes and cannabinoids while also preventing mold and pests requires a delicate balance, and 30% of participants in Cannabis Business Times’ first-ever post-harvest study said they struggle with “maintaining cannabinoid/terpene levels.”

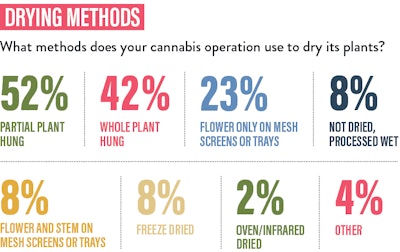

In CBT’s “Special Report: Cannabis Post-Harvest” research, most cultivators indicated they either dry by hanging partial plants (52%) or whole plants (42%). About a quarter of cultivators reported drying flower only on mesh screens or trays (23%), while few reported employing other methods such as processing wet, laying flower and stems on mesh screens or trays, and freeze drying (each 8%).

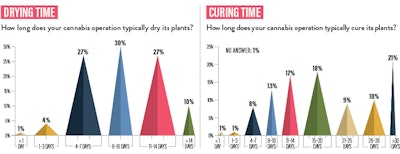

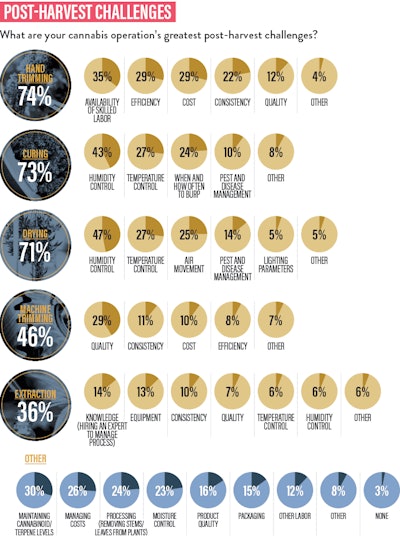

On average, participants said they dry cannabis for about 10 days. However, their optimal drying times range from more than two weeks (10% of cultivators) down to 4 to 7 days (27%). Of note, 71% said drying is one of the most challenging aspects of the post-harvest process.

Curing also is a challenge for many, according to the data. Nearly three-fourths (73%) of research participants said it is one of the most significant post-harvest challenges. The reason? More than 43% of those respondents cited humidity control.

It’s been said that producing quality cannabis is both an art and a science, and curing is perhaps the greatest example of that, a step that requires a careful balance of both. Cultivation teams need to carefully monitor and burp flower to be sure moisture is retained but that mold and mildew don’t develop. Perhaps because of this art-science mixture, typical cure times vary widely among participants, ranging from more than 30 days (21% of cultivators) down to 4 to 10 days (22%).

A Challenging Endeavor

As mentioned earlier in the report, drying and curing, and specifically targeting humidity for those processes, are among the top three post-harvest challenges, according to study participants. However, 74% of cultivators said hand-trimming is the most difficult step and the top challenge noted. The reasons why participants reported hand trimming is so complicated is because of the availability of skilled labor (35%), efficiency (29%), cost (also 29%), consistency (22%) and quality (12%).

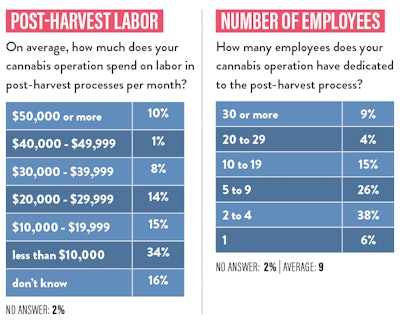

Other than utilities, labor is one of the biggest costs of operating a cultivation facility. When looking at the monthly cost of post-harvest labor alone, 34% of participants reported spending less than $10,000, the most common range selected, while 10% said they spend $50,000 or more, the highest range.

On average, cultivators hire nine employees to run the post-harvest process, according to the research. More than a third (38%) of participants hire two to four people to run their post-harvest operations, while 26% have a team of five to nine people manage drying, curing, trimming and more.

Note: The numbers in charts throughout this report may not add up to 100% due to rounding.

The Right Environment

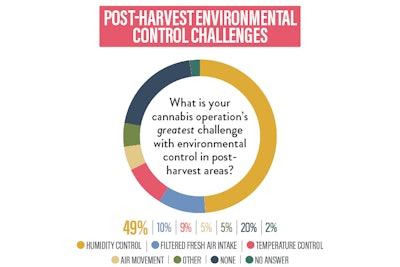

When plants are alive, ensuring they have the best environment to thrive is key to maximizing growth, quality and yield as well as to mitigate pests and disease. Once cannabis is harvested and moves to the drying and curing phase, the environment still can affect product quality, and maintaining appropriate levels is just as important to preventing disease as it is during cultivation. In CBT’s post-harvest research, participants noted that maintaining ideal environmental conditions, especially humidity, is among top challenges.

When asked about overall post-harvest challenges, humidity control is one of the areas participants struggle with most: 47% reported humidity control challenges in drying and 43% in curing.

Focusing specifically on environmental control challenges in post-harvest, cultivators listed humidity control as the greatest challenge, as nearly half (49%) selected this factor as the one they grapple with most. The next most reported challenge with post-harvest environmental control was filtered fresh air intake (10%). According to CBT’s research, cultivators do not have as much difficulty with targeting temperature as they do humidity, as only 9% said temperature control is their greatest post-harvest environmental control challenge. Notably, 20% responded “none” to this question.

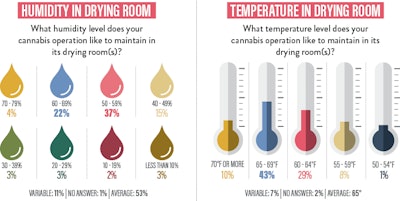

Humidity in Drying

The average humidity level cultivators like to maintain when drying cannabis plants is about 53%. The most common ranges cultivators selected for preferred humidity ranges during drying were 50% to 59% (noted by 37% of research participants) and 60% to 69% (noted by 22%). Fewer participants (15%) reported preferred humidity levels of 40% to 49%, while 11% said they have no optimal humidity level/goal, but instead prefer variable ranges.

Temperature in Drying

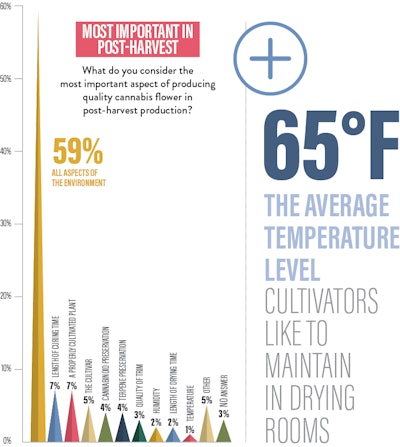

The average temperature cultivators like to maintain when drying cannabis plants is about 65 degrees F. There was more consensus among participants when looking at preferred temperature ranges in drying rooms compared with humidity, as nearly half (43%) said they keep the dials to 65 to 69 degrees F in drying rooms, while another 29% indicated they like conditions just a bit cooler, at 60 to 64 degrees F.

Methods of Control

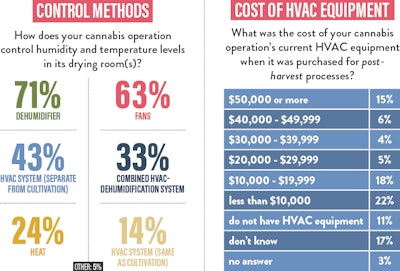

To achieve desired temperature and humidity ranges in drying rooms, most cultivators reported they use dehumidifiers (71%), fans (63%), HVAC systems separate from cultivation (43%) and combined HVAC-dehumidification systems (33%).

Spending on HVAC equipment for post-harvest varied greatly, with 15% spending $50,000 or more and 22% spending less than $10,000. Another 11% said they do not have HVAC equipment for post-harvest, and 17% said they don’t know how much it cost.

Quality

With all the emphasis growers placed on the post-harvest environment throughout the study, it’s not surprising that when asked, “What do you consider the most important aspect of producing quality cannabis flower in post-harvest production,” most participants (59%) selected “all aspects of the environment.” The next most selected answers were “length of curing time” and “a properly cultivated plant,” both noted by 7% of participants.

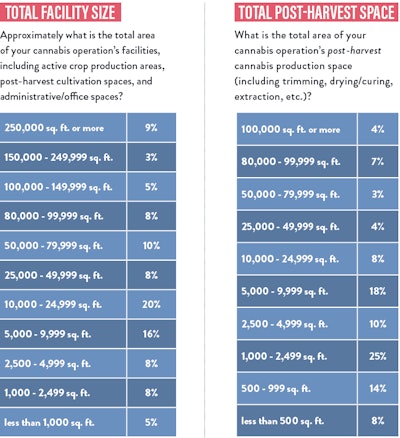

Facility Size and Post-Harvest Spaces

Harvests and Yields

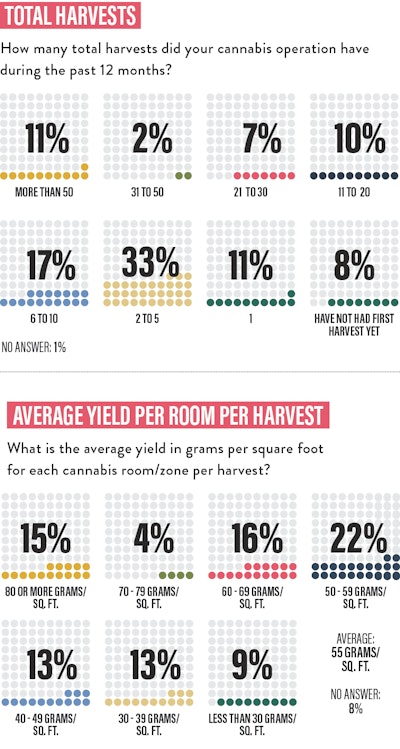

The number of harvests a cultivation company produces in a year depends on many factors, including if cannabis is grown outside or indoors, the facility size, and whether growers are running perpetual harvest systems. Because of that, it’s no surprise that participants indicated a wide range of figures when asked how many harvests their operations produced in the past 12 months. The vastness of that range, however, may surprise some: At the very top of the spectrum, 11% said they had more than 50 harvests in the past 12 months; the same percentage (11%) said they had one harvest in the past year. (Though we cannot assume these are outdoor growers, note that 12% of study participants operate outdoors only.) A third of participants reported two to five harvests, the most of any range provided.

As number of harvests per year is an indicator of yield potential, so is the grams per square foot of flower produced in each room or zone. Participants reported a wide range for this metric, with 15% averaging 80 or more grams/square foot (g/sq. ft.) at the high end, and 9% averaging less than 30 g/sq. ft. foot on the lower end. On average, cultivators said their yields are 55 g/sq. ft., with the largest number (22%) reported achieving 50 to 59 g/sq. ft.

Do Cultivators Package Their Own Products?

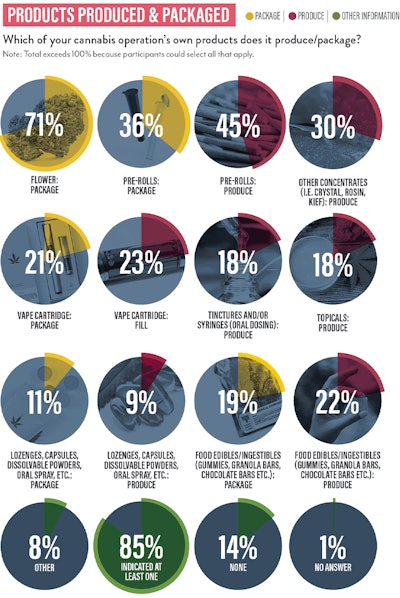

The final step in the post-harvest process is either sending product off to be packaged, distributed and sold, or packaging products in house. As part of the “Special Report: Cannabis Post-Harvest,” CBT explored how many growers are packaging their own products for sale. Most participants (85%) package and/or produce some or all of their own products. The chart below details which products cultivators are producing and which they fulfill with packaging. Other than flower and pre-rolls, “other concentrates (i.e., crystal, rosin, kief)” is the top product category cultivators reported producing, with 30% of research participants indicating they make those in-house.

About the Research Participants

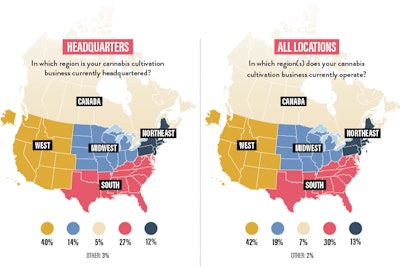

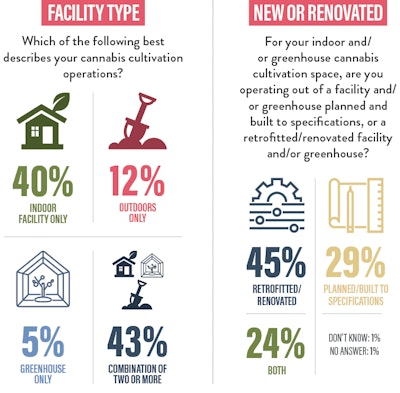

Many participants (43%) said they operate two or more types of cannabis cultivation operations (p. S10). However, more said they operate an indoor facility only (40%) than outdoor only (12%) or greenhouse only (5%). Also, more said they operate retrofitted facilities (45%) than those planned/built to specifications (29%), and 24% said they operate both retrofitted and spec-built. More participants have headquarters and are operating in the West or South than other U.S. regions.