There are many decisions that a grower must make in relation to the production of plants grown in any type of container system. Considerations such as site location, outdoor or indoor production, genetics of plant material, organic or synthetic fertilizers, pesticide/fungicide or herbicide selection, container type and size, irrigation method, and more all have to be established early in the process.

Also near the top of that list of critical decisions is substrate selection, as it can weigh heavily in how you resolve many of the above considerations.

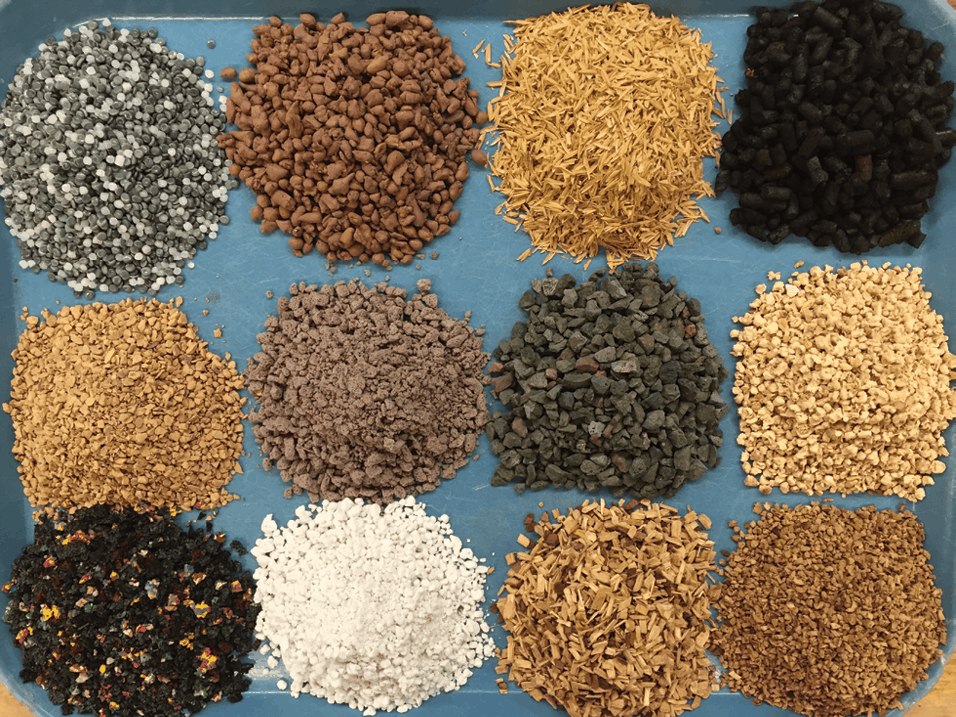

The basic functions of any container substrate are the same as the functions mineral soil serves for outdoor-grown plants: stability, water supply, nutrient reservoir and availability, and adequate air (oxygen) for proper root growth and development. Soilless substrates, organic or inorganic and single component or multiple component mixes (Fig. 1) are used in containers instead of mineral (field) soil for a variety of reasons that have been well established and proven during the past six decades. These soilless materials give growers two of the most powerful tools in managing plant growth and yield: precision and control. The selection of the optimal substrate should be considered carefully.

Choosing Suppliers

The most fundamental pieces of advice I could give someone in the market to purchase soilless substrates are to 1) pick a supplier, not a product and 2) do not let cost be the primary/initial deciding factor in substrate selection. This is true for growers purchasing raw substrate materials with plans to blend their own substrates at their growing operations as well as for growers purchasing pre-blended, ready-to-use mixes. There is a lot to unpack in those two statements, so let me offer some justification to my recommendations.

One of the most valuable attributes of a commercial substrate supplier is the technical assistance experts from those companies who help their customers make decisions and guide them through production problems. The assurance that comes with having someone to call in times of need is often worth paying a little bit more for certain products. Growers who make their own substrates or who buy from suppliers who offer no technical support may be left to figure out problems on their own or forced to bring in paid consultants to help solve their problems.

Another key attribute worth inquiring about is the Quality Control (QC) program that the company has. Engineered substrates are thoroughly designed materials that have been through many years of research and development to get to commercialization. Companies should have strict operating guidelines on raw material acquisition and handling, material processing, material blending, bagging, and shipping. These steps ensure consistency across batches and over time. Suppliers should be regularly checking various material properties, including particle size distribution, wettability, pH, electrical conductivity (salts), physical properties, and plant growth testing, etc. (Fig. 2). Companies with strong QC programs will retain samples of all substrate batches produced and keep them in storage for many months in case a problem is ever discovered. If so, they have a reference with product quality data.

Research and innovation development within companies (depending on size) can be another point of attraction. Is the company planning for the future? Are they offering new products based on research of their own? Are they collaborating or cooperating with university researchers or other industry partners if they do not have a researcher (or team) of their own? Not all substrate suppliers are large enough to maintain large or active research programs, but that should not disqualify them as a potential supplier. However, all suppliers should stay updated on current research, industry trends, and new products and growing systems, as all of these are evolving quickly. As a grower, you should be able to determine if a company is up to speed on the latest industry innovations and developments by comparing feedback with that of other suppliers you talk to by asking the supplier to address how they are staying current and innovative, or by asking other growers about their products and the suppliers they are using.

Environmental Considerations

During the past several years, protecting the environment and its resources has been a priority for many companies and consumers. In a global effort to reduce the environmental impact of growing plants, horticultural growing practices are taking significant steps forward in sustainability, and the substrate industry has been a leader in this effort, as overall, it has focused on utilizing more localized/regional growing media components to reduce freight distances, implementing more advanced peat harvesting and peat bog restoration practices, and developing more organic growing media products to substitute inorganic or non-renewable materials.

If sustainability is a priority for growers, it’s important to ask potential suppliers about their sustainability efforts. There are numerous certifications that substrate producers can participate in to verify their efforts to protect the environment (e.g., Veriflora certification, Global Reporting Initiative (GRI), International Organization for Standardization (ISO), among others). Ask about their efforts in resource conservation, ecosystem protection, restoration efforts, etc. Sustainability efforts also apply to the use of packing materials (plastics), transportation types and the distance supplies travel.

In addition to sustainability initiatives, also ask potential substrate suppliers about their reputation with other growers, variety of product offerings, delivery time and scheduling flexibility, willingness and ability to create customized mixes if requested, online resources for training and grower information, response time to communications (phone calls or emails), etc. The bottom line is that building a positive rapport and developing a working relationship of trust and respect with a supplier is far more important in the long run than price alone.

Choosing Substrates

There are many considerations when matching substrates to your specific needs. The first place to start is to determine if the substrates are for plant propagation (seed germination or cuttings) or for plant production/finishing in larger containers. Propagation substrates are designed and formulated specifically to meet the needs of young plants with developing root systems. Those substrates are not appropriate for larger containers for plant production and finishing because of the ratio of different components and the particle size of those components, as they create different air and water properties as well as drainage and drying properties. For materials such as mineral wool or rockwool, it is the size of the slabs and compression ratio that can change those physical/hydrological properties.

Other criteria for substrate selection include physical and chemical properties, regional availability, crop longevity, blending and mixing problems or issues, ease of automated pot/flat filling, excessive setting or shrinking once in containers, and of course, cost.

Choosing components like peat moss, coconut coir, wood products, and pine bark (Fig. 1, p. 59) can be challenging because there are often many types, grades, and sizes to choose from. Knowledgeable suppliers can ease the burden of having to make those decisions by providing information.

Once a substrate is selected (containing one or more components) then there is the question of which amendments to add, which may include aggregates (Fig. 3) including perlite, rice hulls, pumice, wood chips, or others that can modify substrate porosity and drainage properties. Other substrate amendments may include lime, mycorrhiza, water absorbing polymers/gels, wetting agents, gypsum, starter charge fertilizers, controlled released fertilizers, and organic fertilizers (Fig. 4).

Growers who are using hydroponic systems or hybrid hydroponic systems—substrate in bags or trays that have nutrient solution pulsed through the system and then recaptured—likely use more inorganic materials, including perlite, vermiculite, growstones, and stone/rockwool. The selection of these substrate products may differ than the loose-fill, mostly organic substrates, but the number and type of offerings is likely the same.

(A good substrate manufacturer/supplier will offer valuable guidance in this selection process.)

The dedication the growing media industry in North America has to growers, both large and small, should serve as a comfort to growers (of any crop, generation, or experience level) that they do not have to make decisions alone or face challenges and production-related issues without guidance and assistance. The efforts, resources, and innovation of the growing media industry is second to none in horticulture, and with the future of container plant production gaining in value, importance, and acreage their efforts will only continue to grow.

Explore the October 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Cannabis Business Times

- Navigating Cultivation Room Design: Optimization vs. Maximization

- Verano Opens 18th Medical Cannabis Dispensary in Pennsylvania

- Hundreds Interested in Kentucky’s Medical Cannabis Licenses; Just 17 Apply So Far

- Aurora Receives Expanded Cultivation, Unique Research Licenses for German Facility

- Curaleaf Opening 2 New York Medical Dispensaries, Launching Adult-Use Sales at 2 Other Stores

- Ohio’s Adult-Use Licensing Process Leads CBT’s Top Stories in July

- Planet 13 Launches Lifestyles Brand Company; Signs 1st Sponsored Athlete in UFC Title Contender Chito Vera

- LeafLink Acquires Leading Cannabis Banking Platform Dama Financial