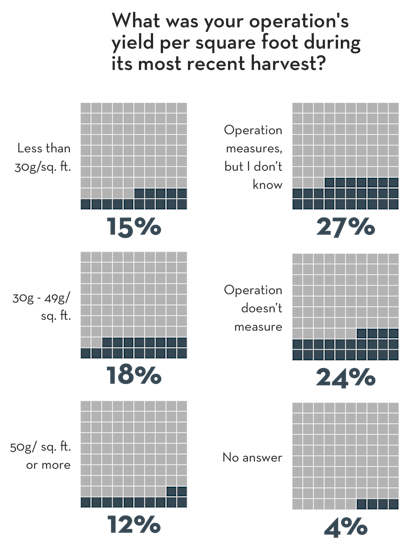

Yield is the holy grail of cannabis cultivation. So, it’s not surprising that most professional cultivators measure yield in some form. Most — nearly three-fourths (72%) of the cultivators who participated in CBT’s research project — say they measure yield per square foot. However, 38% of those who say they measure this metric didn’t know the actual yield per square foot of their cultivation operation’s most recent harvest, and some respondents who elaborated further on the question indicated they measure this metric somewhat informally.

Joe Romano of The Indoor Garden Shop in Detroit, Mich., who participated in the research project, says that his operation measures yield per square foot “in a roundabout way.” His team looks at “given a particular space, how many harvests can we get in a year,” he says.

Measuring yield per square foot, he believes, is one of the more important stats to track, if even informally, but looking at yield per strain also is important. “I think we spend more time balancing looking at different strains [and] … what they produce,” Romano says. “For example, the majority of what we’ve been growing lately is Gorilla Glue, [for] which yield per square foot is fantastic compared to a number of sativas. Ours have been more of a focus on a variety of plants and [their] marketability than anything else.”

Vince Hanson, cultivation director at Leaf on the Mesa in Pueblo, N.M., another participant in the research, also believes measuring yield per square foot is important (“You can have all these lights in the room, and you can be wasting a tremendous amount of square footage,” he says), but time constraints have not yet enabled his team to do so. “This grow started about a year and a half ago. We just got over all of our weird growing pains,” he says. “And so … the last six months, we’ve been producing steady.”

In the future, he says, Leaf on the Mesa will probably track this metric.

Right now, Hanson says, ‘We look more for our averages. … We have to do a wet plant weight and a dry plant weight, so when I enter everything into the metrics, I can find an average plant weight. So if I find a drop-off in the average plant weight, there’s something going on, wherever they came out of, or something going on with the strain. So I pretty much focus on average yield,” he adds. “I keep logbooks of everything. … I build spreadsheets for all of these and print them off. As they harvest plants, I write down its tag, its wet weight, its waste weight, its bud weight, all those things.”

Research participant Robert Mead of Sound Cannabis in Aberdeen, Wash., says his business does not measure yield per square foot, but, he says, “that’s something we’re going to be looking at specifically. I’m watching the market, and the prices are starting to come down. I see a lot of really cheap concentrates in the market, so I really want to look at my return on investment.”

Yield per square foot ranged among research participants from 60g/sq. ft. or more to less than 20g/sq. ft., but the average yield per square foot, during the most recent harvests, rested just about in the middle at 39.5g.

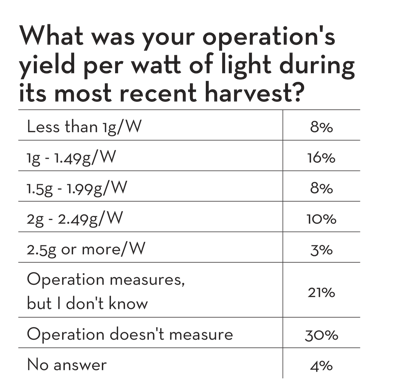

Another metric that some cultivators feel is even more important to measure than yield per square foot is yield per watt of light; however fewer measure this than yield per square foot. Two-thirds of respondents (66%) say they measure yield per watt of light; but, again, nearly one third (31%) of those cultivators say that their operations measures this, but that they don’t know what the yield per watt of light was during their most recent harvest.

Thirty percent of cultivators say they don’t measure yield per watt of light at all.

Jacob White of R. Greenleaf Organics LLC in Albuquerque, N.M., says, “We track all of our production by grams per watt of lighting. We add up the total yield of all primary and secondary bud and divide by the number of watts illuminating the room.”

This metric is important to measure, he says, because of New Mexico’s canopy limit. “Because of a restrictive plant count (450 plants total), we must grow larger plants. Because of variation in yield between strains, we have varying amounts of plants in each flowering room to compensate. Comparing rooms in terms of grams per watt allows us to compare apples to apples,” Greenleaf says.

“Over an almost two-year period, we have a historic average of .96 grams per watt,” he says. “Our yields are always improving over time, and over the last six months, we are a little higher at 1.02 grams per watt. In the last 10 harvests, we are averaging even higher at 1.08 grams per watt.”

Casey Connell of Contender Gardens in Spokane, Wash., says Contender also measures yield per watt “for the most part. We keep track to see how we are doing.”

Currently, Contender is yielding “very close to 1 gram per watt,” Connell says.

Romano says The Indoor Garden Shop doesn’t exactly track yield per watt, but that metric is important to have a sense of, if even through more of an estimation. “What we’ll do, given a particular set of plants in bloom, they’ll be under anywhere from two to four 1,000-watt lights. We tend to look at, well, this month we got X number of grams from that setup, and last month we got 10 percent more or less. We just don’t do the calculation. It’s more from the production perspective. If we had 4,000 watts of light, how many grams did we get?” he says.

While Mead says Sound Cannabis hasn’t yet measured yield per watt of light (“We have not had a crop come out with the systems we’re installing right now,” he says), he sees this metric as the most important, as it takes into account energy usage and efficiencies. “The power is the biggest consumable cost,” he says. “Is it going to try to mimic the sun inside? Well, it’s going to cost you. I’m really straying away from all-indoor grows. I’m looking at hybrid buildings.”

Yield/watt of light ranged among participants from less than 1g/W to 3g/W or more, but the average yield per watt, for participants’ most recent harvests, fell at 1.6g/W.