Data—and data collection—should be the heart of any cultivator’s operation. Collecting data in all forms allows a cannabis business to have better information with which to solve problems, and can help a company identify where it can operate more efficiently. In an industry with an increasingly competitive outlook and tightening margins, this is essential to any business looking to thrive. Developing a deep understanding of what is going on in your grow operation will also allow you to scale effectively without encountering costly issues and setbacks.

However, while gathering data is important, cannabis business owners across the industry tend to measure their data in different ways. This is a problem, because inconsistency in data collection makes it more difficult for growers, equipment manufacturers and business managers to drive the industry forward. For example, anyone who grows has likely been asked how many grams per watt they are producing, or how many pounds per square foot, or grams per cubic feet, etc. Additionally, and understandably so, cultivators tend to focus on this type of plant data—harvest results—rather than what truly makes the plants succeed.

Most often overlooked is environmental data, especially when harvest result numbers more easily translate to dollar figures. However, your environment should be the first thing that you focus on, not something you just check on occasion to see how your temperatures and humidity are sitting—and the only way to know what is going on with your environment is to measure it regularly.

Data Points to Look For

Unfortunately, there is no one-size-fits-all system when it comes to gathering data on your grow environment. Successful cultivation businesses implement the data collection systems and methods that are the most effective and efficient for their operations. In order to do this, a business should look at how best to record and analyze the following information, at a minimum:

- plant count,

- water usage,

- temperature,

- relative humidity (RH) and

- CO2 levels.

These data points should form the core of the information you collect every day. Here are some other data points to consider tracking:

- air quality (molds and airborne particles, all spaces),

- photosynthetically active radiation (PAR) values (all spaces),

- outside temperature, humidity and CO2,

- watering schedules,

- nutrient schedules and formulations,

- coolant circulation pressures,

- chiller/HVAC set points and operating temperatures,

- growth phase in which data points are measured, and

- harvest rotation.

Once you become familiar with your processes and collect more data to understand every detail of your building, grow and production spaces, you will be able to maximize the space’s efficiency.

3 Tips for Data Collection

1.It is important to take consistent measurements in the same spots in your grow space every day. Building a complete picture of what is going on in your grow rooms takes time, and taking consistent, repeatable measurements of your environment is the best way to get the clearest understanding. Taking multiple measurements in each space is ideal.

2.Remember that it takes time for your environment to respond when you change something. If you change a thermostat by even a degree or two, whether you are running a traditional HVAC air exchange or a chilled water system, it might take a few days for the environment in that area to totally stabilize. The data you collect each day will tell you when you are seeing the effects of any changes you make.

3.A plethora of tools are available for environmental data collection. Remote temperature and humidity sensors are cheap and relatively reliable. Look into what type of technology might streamline your data collection process. Find the technology that makes it easy to combine all your data points into one place. Once you have a consistent data collection routine, and you have your information organized, you can start the fun part: analyzing the data.

Run the Numbers

Don’t be afraid to get cozy with your numbers and do the math yourself! Many online tools are available to help growers with calculations. A quick Google search will lead you to calculators, from supplier companies and associations, for different types of inputs.

The insight that you gain from your analysis will help you answer important questions about your cultivation processes, such as: How does my water use change over time? How do the changes in water uptake translate to increased or decreased humidity load? If I change my flower room temperature, how will that effect the efficiency of my dehumidifier system? If I make changes to my CO2, temperature or humidity levels, how will those impact the health and yield of my plants? If I increase the number of plants in the space, will the environmental system have the capacity to still perform the way I want? All these questions are essential for anyone who wants to continue to scale their business and develop successful cultivation practices.

The Benefits of Data Analysis

The capabilities and efficiencies of equipment are always changing, and data analysis can help you identify improvement areas. For example, if you have a dehumidification unit that can pull more pints per kilowatt-hour (Kw/h) than another, the cost-savings for powering that unit every day can add up and be substantial.

Keeping accurate environmental data will also allow cultivators to stay ahead of potential problems. Often, growers will see changes in the environmental data that will let them know a piece of equipment is failing long before a costly repair becomes necessary or crop damage ensues.

Finally, taking a detailed look at your grow environment on a regular basis is vital to every grower’s bottom line. Running equipment such as lights, cooling units and dehumidifiers unnecessarily can be very costly for a grow operation and can ultimately be the difference between business success and failure. Similarly, not having enough control capacity can negatively affect yields and cannabinoid content. All of this can cost a business dearly.

Successful growers understand their grow environment and what it takes to maintain it in an ideal range. If you have a great environment, the increased results you see in your yield data will be clear.

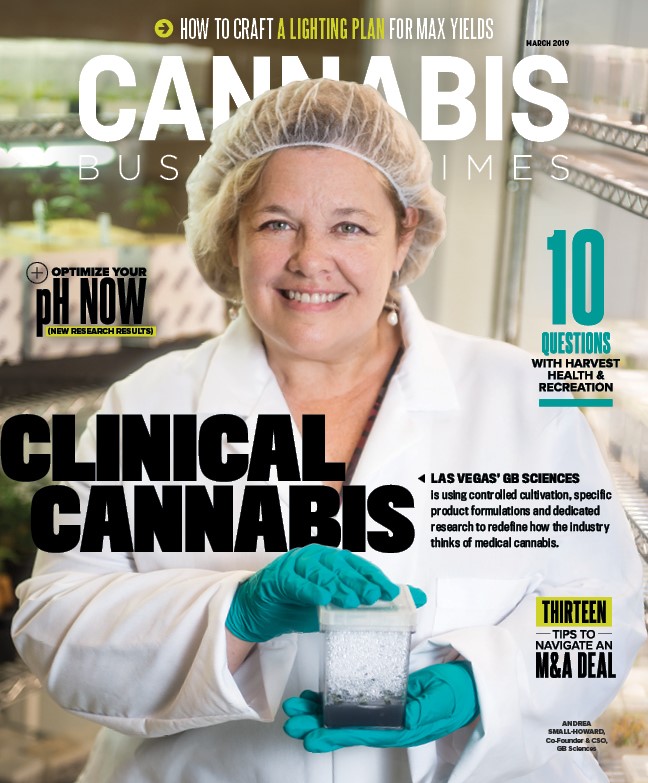

Explore the March 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Cannabis Business Times

- Navigating Cultivation Room Design: Optimization vs. Maximization

- Verano Opens 18th Medical Cannabis Dispensary in Pennsylvania

- Hundreds Interested in Kentucky’s Medical Cannabis Licenses; Just 17 Apply So Far

- Aurora Receives Expanded Cultivation, Unique Research Licenses for German Facility

- Curaleaf Opening 2 New York Medical Dispensaries, Launching Adult-Use Sales at 2 Other Stores

- Ohio’s Adult-Use Licensing Process Leads CBT’s Top Stories in July

- Planet 13 Launches Lifestyles Brand Company; Signs 1st Sponsored Athlete in UFC Title Contender Chito Vera

- LeafLink Acquires Leading Cannabis Banking Platform Dama Financial