Within the cannabis and hemp industries, the utility of CO2 for extracting cannabinoids and terpenes from dried plant material is widely known and accepted. As an extraction solvent, CO2 is cheap, clean, nontoxic and nonflammable. However, what may come as a surprise (especially to those new to cannabis and/or hemp processing) are the significant cultivar-to-cultivar differences when performing CO2 extraction runs. Extraction scientists should consider several key questions when developing cultivar-specific CO2 extraction protocols.

1. What is the extraction goal?

Prior to creating any new CO2 extraction protocol, it’s important to consider the desired outcome. Is the goal to extract all the desirable compounds from the biomass as quickly as possible? Is terpene preservation or oil fractionation (a separation process) important? The answers to these questions will determine whether you utilize supercritical or subcritical CO2 extraction, or a combination of the two.

Supercritical CO2 extraction takes place at pressures above 1,083 psi and temperatures greater than 88oF when the CO2 has reached its critical point where liquid and vapor coexist. Behaving like a gas, supercritical CO2 expands to fill the volume of the extraction vessel and can freely diffuse through ground cannabis or hemp material within the vessel. Behaving as a liquid, supercritical CO2 has great solvent power capable of extracting a wide range of compounds from biomass with a greater percent yield in a shorter amount of time compared to subcritical. Because supercritical CO2 extraction employs higher temperatures and pressures, terpenes and other more volatile compounds may be degraded or lost during the process.

Subcritical CO2 extraction occurs below the critical point (less than 1,083 psi and lower than 88oF) where CO2 is in the form of a liquid. While subcritical CO2 has decreased solvent power, this can be advantageous, as it allows for more selectivity in the extraction process. Subcritical is ideal for extracting terpenes and other more volatile compounds from cannabis or hemp, and many of the more undesirable components (fats, waxes, and chlorophyll) are not readily soluble in subcritical CO2. This is useful because subcritical extraction is capable of fractionation, producing oils rich in CBD, THC, and other cannabinoids. The cooler temperatures used in subcritical also mean there is minimal decarboxylation that occurs in the process, preserving the acid forms of CBD and THC (CBDA and THCA) that are naturally present in the plant. The major drawback is time—subcritical CO2 extraction generally takes two to four times longer than supercritical to get the same yield.

(The best conditions for using a combination of these two methods will be addressed later.)

2. What is the next step for the extracted oil?

A closely related question to the first one: What do you plan to do with the cannabis or hemp oil once it is extracted? Will it undergo winterization to remove waxes? Will it be distilled? Will it need to be decarboxylated for use in food products or oral dosage forms (capsules, lozenges, tinctures)? The post-extraction processing/purification pathway will help guide in the development of your CO2 extraction process. For example, if you plan to perform thin film distillation on the extracted oil, you could likely get away with doing a higher pressure supercritical CO2 extraction run, which would result in a faster run time, but the extracted oil would be less refined.

3. What is the cannabinoid composition of my starting material?

This question is key when it comes to CO2 extraction method development. Studies have demonstrated that THC, CBD, and other cannabinoids have differing solubility in supercritical CO2, with CBD having higher solubility compared to THC (see “References” sidebar for studies on that subject). While the researchers in these studies determined cannabinoid solubility at a relatively high range of temperatures (greater than 100ºF) and pressures (more than 2200 psi), similar trends in THC and CBD solubility are observed in practice at lower temperatures and pressures.

When extracting using the same parameters for temperature and pressure, we have consistently observed that hemp/CBD-dominant cannabis cultivars extract much more efficiently than high THC cultivars. Of the high-CBD strains we process, total extraction run time is two- to three-fold less than their high-THC counterparts, yet achieves the same yield of raw oil. The raw CO2 extract from high CBD strains generally is less viscous compared to high THC extracts, making for easier recovery and cleanup.

For high THC cannabis strains, we routinely perform a series of CO2 extraction runs spanning both sub- and supercritical parameters to fractionate terpenes and cannabinoids. Performing additional extraction runs on the same feedstock also ensures that you recover as much THCA as possible from the biomass and optimize extraction yield. If you plan to perform some type of post-processing on the extracted oil (as described previously, in the answer to the second question), you can save time by performing a single supercritical CO2 extraction run.

4. How do I develop/optimize a cultivar-specific CO2 extraction method?

Most manufacturers of CO2 extraction equipment will provide a set of basic parameters for both sub- and supercritical extraction in their operating instructions. While this is an obvious starting point, we have experienced great success systematically changing time, temperature, and pressure settings to achieve optimal extraction results. To ensure you know how the change is impacting the extraction run, only change one parameter at a time and clearly document the times, temperatures, and pressures observed. With this information, you will be able to correlate method parameter changes to changes in yield and cannabinoid potency. Don’t be afraid to experiment! Most CO2 extractors operate over a wide range of temperatures and pressures, and it is helpful to collect extraction data covering this range—the ideal parameters for your cultivar may not align with predictions.

While we expect and routinely observe extraction differences between hemp/CBD-dominant cannabis cultivars and high-THC cultivars, we have also noted cultivar-to-cultivar differences within each class. We have witnessed substantial differences in extraction efficiency/oil potency between numerous high-THC cannabis cultivars run using the same extraction parameters. In some cases, these differences were overcome by increasing the extraction pressure or run time, while in others, we re-extracted the same biomass to strip out the remaining THCA.

In comparing extraction efficiency cultivar-to-cultivar, it is very helpful to monitor cannabinoid potency in the extracted oils as well as in the spent hemp/cannabis feedstock. This will help determine when the extraction run is complete as well as determine which parameter changes result in a higher potency oil.

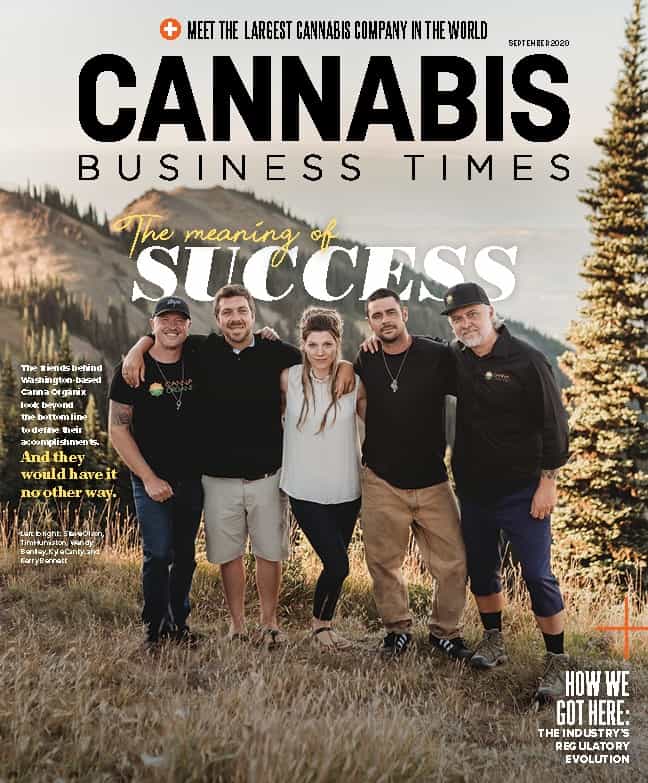

Explore the September 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Cannabis Business Times

- Navigating Cultivation Room Design: Optimization vs. Maximization

- Verano Opens 18th Medical Cannabis Dispensary in Pennsylvania

- Hundreds Interested in Kentucky’s Medical Cannabis Licenses; Just 17 Apply So Far

- Aurora Receives Expanded Cultivation, Unique Research Licenses for German Facility

- Curaleaf Opening 2 New York Medical Dispensaries, Launching Adult-Use Sales at 2 Other Stores

- Ohio’s Adult-Use Licensing Process Leads CBT’s Top Stories in July

- Planet 13 Launches Lifestyles Brand Company; Signs 1st Sponsored Athlete in UFC Title Contender Chito Vera

- LeafLink Acquires Leading Cannabis Banking Platform Dama Financial