DENVER, Dec. 9, 2019 /PRNewswire/ -- PRESS RELEASE -- Willow Industries, a provider of cannabis decontamination technology, has announced the opening of the first non-extraction based cannabis remediation facility in the country, located in Watsonville, Calif. The centralized WillowPure Processing Center will offer a streamlined and convenient cannabis cleaning process for any licensed growers in California. The facility began operating on Oct. 7, 2019.

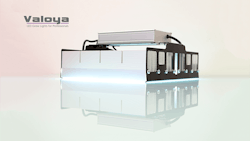

Willow Industries is innovating cannabis decontamination for growers forced to remediate harvests that fail state-mandated microbial testing, as well as those looking to incorporate a preventative treatment step in their harvesting process. The revolutionary Processing Center is home to a permanent WillowPure system, the company's proprietary cannabis cleaning technology, and brings this one-of-a-kind cannabis decontamination solution to California growers.

"We built the first cannabis remediation facility in California to support growers who are committed to addressing contamination issues in the industry," said Jill Ellsworth, founder and CEO of Willow Industries. "This facility will not only preserve the profits of more cultivators but also ensure safer products for consumers."

Until the opening of the WillowPure Processing Center, the only option for decontaminating harvested product was to process cannabis flower into concentrate, which sells for only a fraction of the flower's value. Otherwise, harvests that fail testing must be destroyed. Willow offers a new solution to this $3 billion-plus problem.

California tests for several harmful microbial contaminants common in cannabis, including four different strains of Aspergillus, a pathogen that can survive combustion and cause severe infections if inhaled by consumers with a compromised immune system. Aspergillus strains are responsible for the majority of pathogen batch failures. WillowPure technology effectively reduces Aspergillus and ensures that consumers are buying safe, clean cannabis.

The WillowPure system uses an ozone-based decontamination process that maintains the essential medicinal and chemical properties of cannabis, while significantly decreasing the number of microbials. It can decontaminate flower at two different points in the harvesting process. The system can be used as a microbial kill-step earlier in the production process to improve the pass-rate of harvests going through initial testing. When not used as a kill-step, the system can be used to remediate flower that has failed initial microbial testing.

"Willow is breaking new ground with the launch of an easy-to-access health and safety solution for the highly regulated cannabis industry," said Ephraim Lindenbaum, Willow board member and managing director of Advance Ventures. "High-value central processing services are industry standard in the traditional food and agriculture supply chain. Willow's central processing services provide a critical health and safety solution for the rapidly evolving cannabis industry."

When a harvest fails initial microbial testing, California law requires cultivators to develop and submit a remediation plan to the California Department of Public Health (CDPH) for approval. If remediation is necessary, growers can now send product to the WillowPure Processing Center to be cleaned and returned for a final round of testing. Willow will also submit the required remediation plan to the state and assist with scheduling transportation, streamlining the remediation process for growers and facility managers.

"The recent news about the dangers of vaping highlights the need for only clean and non-contaminated cannabis flower and cannabis oil to be used by all consumers," said Dr. Ramie Tritt, a leading ENT and nasal-sinus surgeon. "Willow Industries is focused on providing consumer safety-focused solutions for the cannabis industry. The new WillowPure Processing Center is an effective, safe and easy way for cannabis cultivators and processors to utilize the cannabis-cleaning technology, that benefits all in the cannabis industry and most importantly the cannabis consumers."

Willow built the facility in partnership with Strong Agronomy, a leading California cultivator and manufacturer, who will handle day-to-day operations and ensure Willow's high service standards are consistently met. At launch, the facility will be able to process tens of thousands of pounds of flower per year, and as demand increases, Willow will add more machines to improve throughput. With a pay-by-the-pound pricing structure, the WillowPure Processing Center is the most affordable, non-extraction-based remediation solution available to California growers.