Editor's Note: This popular article originally appeared in the September/October 2016 issue of Cannabis Business Times as part of the first "State of the Cannabis Lighting Market" report. The now annual, highly anticipated study is in its fourth year. You can read the 2019 report here.

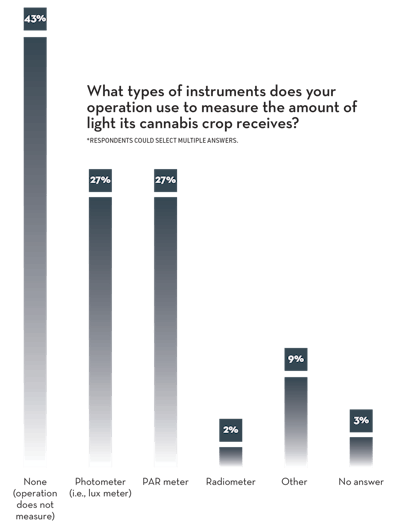

While it’s interesting to see what types of lighting cultivators are using, other data offer a more candid look at where the industry stands regarding light-related data tracking and application to impact yield.

One of the most basic, yet essential measurements, say some experts, is calculating how much of your lighting is actually reaching your cannabis crops. According to CBT’s research, 43% of participating cultivators say they do not measure the amount of light their crops receive.

Randy Flemming, sales associate at American Cannabis Consulting (ACC), says he believes “43% is an accurate number, with that number dropping all the time. People are becoming more aware of the potential loss of capital through lighting wastage,” he says.

He adds that ACC measures light output for several reasons:

- To maximize the effectiveness of the light available.

- To ensure a consistent photosynthetic photon flux density (PPFD) at the canopy.

- To help “fine tune” your photosynthesis, allowing your plants to grow strong and healthy.

- To allow you to recognize a drop in lighting effectiveness, thus allowing for proper bulb change-out and/or maintenance.

Some experts have suggested cultivators also measure the amount of light that is reaching any empty spaces around the canopy; this is wasted light, and finding excess light in non-crop areas can help you redirect your lighting to maximize its use.

We track all of our production by grams per watt (of lighting). We add up the total yield of all primary and secondary bud and divide by the number of watts illuminating the room.” — Jacob White R. Greenleaf Organics

“To us, these findings reflect a warehouse-dominated industry where light variation has been eliminated, along with regular measurements,” says Kurt Badertscher, co-owner with his wife Kerrie of Otoké Horticulture LLC, a horticultural consultancy.

“In contrast,” he says, “sunlight in year-round greenhouses varies widely. Yields follow light, so for consistency, daily light delivery needs to be held constant, and that requires automated or manual, daily light monitoring to determine sunlight deficits that supplemental lighting makes up for.”

Of the 55% who say they do measure the amount of light reaching their crops, Photosynthetically Active Radiation (PAR) meters and photometers (lux meters) are used by the largest number of cultivators, with both measuring tools being used by 50% of those respondents.