As a cultivator for major markets such as Washington, Oregon and Nevada, I’ve had the opportunity to learn how to avoid the pitfalls that face large cultivation facilities, as well as experiment in creating an environment that adapts to mechanical failures or attempted interventions from Mother Nature. Here are a few keys to indoor HVAC success I’ve developed along the way:

1. Construction.

The trick from the get-go is to properly build or retrofit your facility. A poorly planned grow is a formula for disaster. The most critical element is to build the right environment, and the cultivator will succeed. Work with a mechanical engineer who has experience building large-scale cultivation facilities. Don’t assume contractors know how to design one. It takes a team of contractors and cultivators, it takes multiple minds, and not many people have it down perfectly. Most HVAC engineers have not worked on large-scale cultivation facilities, for example.

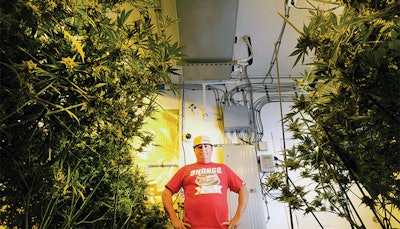

Sealing the environment is also critical. Do not allow exposure to outside elements because your system can’t be dependent on the weather. In addition, make sure there are enough units in your grow to get the job done. (To determine equipment requirements, consult with your designer as well as a mechanical engineer.) What I’ve learned is that the problem with one or two units is that if you lose one, there goes 50 percent of all of your HVAC. If you have to wait for a repair, your grow can suffer greatly. At Shango, we use four with multipliers for space and temperature that assure we provide adequate amounts of AC.

In our opinion, a common downfall is if an economizer, which uses outside air to cool the indoor space, is implemented. The only thing we use outside air for is purging CO2 out at night when our plants are sleeping. Even that air is filtered and climate-controlled to prevent pests or pathogens from coming into the garden. Of course, when you have exhaust, you need intake air pulled from someplace else. If that air is unfiltered, there is the potential to pull in disease and pathogens.

2. Zoning.

In a typical square room, use properly ducted HVAC quadrants. When one goes out, three quarters are going to run nicely if you duct the AC so it covers your whole space. Shifting air flow requires more ducting, which can be hazardous. The more ducting, the more restriction and potential for pathogens. Then you must also sanitize miles of ducting. Run minimal ducting unless the room is large, and run ducts off into different directions that can be altered for adequate air movement.

3. Backup.

In our view, temperatures of 77 degrees with 55- to 60-percent humidity are desired, and this should be consistent throughout the species. A system breakdown can wreak havoc, so you should have sensors wired into the system to maintain temperature. You also need a system where the lights will dim or shut off if you have a unit failure, to reduce the heat on the plants. If two units went out, they could dim or turn off half of the lights and continue as normal with no stress to the plant. It’s critical to sense change and act accordingly, so make a small investment up front that will protect you from crop failure.