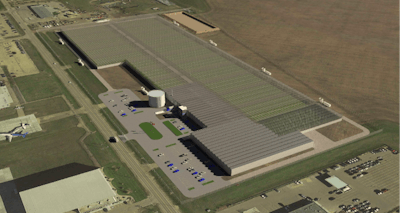

Slightly more than a month after Cam Battley assumed the executive vice president role at Aurora Cannabis Inc., the company announced plans to build an 800,000-square-foot cannabis production facility at the Edmonton International Airport in Alberta, Canada.

Aurora, which earned $9.9 million in calendar year 2016, expects to benefit from services available on site, including bonded warehousing, ground transportation access and air cargo connections across the country after construction is completed in the second half of this year. Production is expected to begin before the year’s end.

The move is part of the company’s plans to meet rapidly growing demand driven by the medical market and pending legalization of recreational use in Canada.

Aurora received its medical sales license in November 2015 and is one of 38 licensed producers (LPs) across Canada, and the only one located in Alberta. Aurora's wholly-owned subsidiary, Aurora Cannabis Enterprises, Inc., is a licensed producer of medical cannabis. It currently operates an expandable production facility in Mountain View County, Alberta.

As executive vice president, Battley plays a key role in Aurora Cannabis’ growth efforts. He has worked for more than 15 years in the pharmaceutical and biotech sectors and also serves on the board of directors of Cannabis Canada, the trade association for licensed producers of medical cannabis. Battley recently spoke with Cannabis Business Times writer Jonathan Katz about the forthcoming Aurora Sky facility, his company’s goals and leadership experiences.

Jonathan Katz: What are your biggest challenges as a senior executive of a cannabis LP?

Cam Battley: Canadian cannabis companies are in start-up or growth phases, so a key challenge for any executive is simply to ensure that everything that needs to get done actually does get done – and it’s an extensive list. So the days are long – and often the nights, too. But on the flip side, the work is fascinating and deeply engaging.

Katz: What prompted your decision to build a large cannabis production facility at the Edmonton International Airport?

Battley: In Mountain View County, Alberta, Aurora currently operates one of the largest-existing production facilities at 55,000 square feet. But that won’t provide us with sufficient production to meet rapidly rising demand. So we have to expand, simply to meet the needs of the medical market, as well as the anticipated post-legalization consumer market.

For context, there are now more than 130,000 registered patients in Canada’s national medical cannabis system – a figure that’s growing by 10 percent per month. In the spring of this year, the federal government will be introducing legislation to legalize the consumer use of cannabis, and analysts project that market will reach 5 million Canadians.

... That’s why we’re building the Aurora Sky facility at Edmonton International Airport. ... It’s designed, without compromise, to achieve three key objectives: massive scale, high quality and low per-gram cost of production.

Katz: Why did you select the Edmonton Airport as your location?

Battley: This is the world’s first cannabis production facility located at an international airport. ... Beyond the availability of excellent utilities, being sited at a key transportation nexus, with immediate access to courier services, is directly aligned with our e-commerce strategy. We believe we can offer our clients the same level and quality of service as retail giants such as Amazon.

(Editor’s Note: Canada’s Access to Cannabis for Medical Purposes Regulations ((ACMPR)) requires that the distribution of medical cannabis be done through the state-run postal service Canada Post; dispensaries, although present in certain cities, are illegal.)

Aurora is the only licensed cannabis producer to offer a mobile application, available for Apple and Android, for registered patients to purchase legal cannabis. ... Clients love it, and it has reduced phone calls to customer care by about 35 percent.

In addition, Aurora is the only licensed producer to offer same-day delivery to two major metropolitan centers – Calgary and Edmonton. We intend to build on this platform to expand same-day and next-day delivery to more locations, which makes the airport location a significant strategic advantage.

Katz: An airport seems a strange location for a cannabis operation – especially considering it is not federally legal in Canada for recreational purposes. Were there any additional regulatory hurdles you had to overcome to secure that location?

Battley: The new facility is situated on 30 acres of leased federal land, and we’ve encountered no hesitation. We operate under rigorous Health Canada regulations and provide legal medical cannabis to patients with a prescription. ... We work with federally chartered banks, and are publicly listed on the Toronto Venture Exchange. The team at Edmonton International Airport have acted as true partners across the board, and we’re looking to have a long and mutually-beneficial relationship with them.

Katz: What are some of the more innovative/state-of-the-art features in this facility? How will these features help you grow and be more competitive?

Battley: It will be a hybrid greenhouse – a closed system with forced air and over-pressurization – and will allow us precise control over all critical environmental variables, including light, temperature and humidity.

The glass is the most advanced on the market, double anti-reflective, allowing the maximum amount of light to pass through, without being reflected back. And the light will be diffused, enabling the highest penetration into the plants. ...

The whole facility will be automated, based on a mobile bench system allowing us to virtually eliminate human presence in the growing bays, with the exception of inspections. ...

Surveillance of the crops will be raised to a new level with the addition of crane-mounted cameras. The cameras will monitor the plants, with programming to detect pests, disease or signs of stress.

Katz: Can you talk about the costs of the new facility build-out, from start to finish, and how the project is being financed? And how long a burn rate do you anticipate?

Battley: We haven’t yet announced the cost of our expansion plans, though we will shortly. ... To our knowledge, we have the strongest cash position in the sector. In our last quarterly report, we disclosed that our cash position exceeded $50 million, and in January 2017, we announced an additional financing of up to $75 million, So we believe the new facility is fully capitalized.

Katz: Can you offer some insights in terms of scheduling a project of this scale? How do you time all the permits required, the construction, inspections and all the additional regulatory hurdles required of licensed producers to schedule an anticipated opening?

Battley: We’re fortunate in that our CEO Terry Booth has extensive career experience in permitting and construction and has assembled an expert team to manage the process under his supervision. ... It’s a top priority, and we’re targeting completion before the end of 2017, so we’re taking a very methodical approach to ensure we stay on track and on schedule.

Katz: Were there any lessons you learned from the development and operation of your first facility that enabled you to prepare better for the new facility?

Battley: Our current facility was purpose-built ... as opposed to trying to convert an existing warehouse, for example. Our Mountain View County site has turned out to be essentially ideal for cannabis cultivation under GMP [good manufacturing practices] conditions. ...

Another lesson we can apply from previous experience is the immense value of selecting the most skilled and experienced partners in design, engineering and construction. We’ve validated that higher-quality partners, committed to the project’s success, are worth the investment.

Katz: What’s next for your company? Are you anticipating selling into the recreational market if or when cannabis is legalized federally in Canada?

Battley: In January, we received our Health Canada license to sell cannabis oils, and that combined with our expanding sales of dried cannabis is expected to deliver continued, rapid revenue growth. We’re also integrating additional advanced technology to enhance efficiency at our existing production site, and have more innovations to come with our mobile app.

With the federal government committed to beginning the legislative process to legalize the consumer use of cannabis this spring, we’re clearly envisioning participating in that market as well. So this year will be about continued growth, completing Aurora Sky and bringing it into production, and preparation and positioning ahead of the legal adult consumer market, which we anticipate will begin in 2018.

Katz: What are a couple of the best business decisions your executive team has made at Aurora Cannabis?

Battley: To begin with, our CEO and founder Terry Booth, has always had a very clear vision and excellent understanding of the critical success factors in the cannabis sector. One of the best initial decisions he made was to construct a purpose-built cannabis production facility, rather than trying to convert an existing building. ... We’re very proud of our branding and positioning under the leadership of our Chief Brand Officer Neil Belot. He and his team have taken great care with everything from our packaging, to the functionality of our mobile app, to ensuring that the overall customer experience with Aurora is simply excellent.

We’ve also continued to enhance our corporate governance with the addition of new board members with keen financial acumen, and extensive experience in mature industries such as biopharmaceuticals, which is my own career background as well.

As fast as our company and the broader industry are growing, we’re working hard not just to execute well on our business strategy, but at the same time consciously build a grown-up company that will thrive over the long term.