In 2018, we received permits to grow and research cannabis (low THC/high CBD), and now we are broadening our research palette to include the needs and opportunities of the ever-growing cannabis industry.

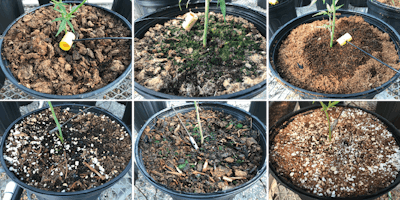

This industry, due to legal hurdles and crippling stigmas, is somewhat deprived of scientific literature on many production practices and issues. Growers and industry professionals rely heavily on personal experience and information from other industries (e.g., floriculture and greenhouse science). Although hands-on experience is an invaluable source of knowledge, having scientific information to fall back on can greatly expedite the learning process for growers, both experienced and inexperienced. A specific area in need of information is that of container substrates.

Overview of Substrates & Soils

Substrates can be composed of organic or inorganic components, or a mixture of both, that create the container environment in which a plant will grow and thrive. Numerous organic and inorganic components have been used in container crop production over the years. One of the most important things to remember is that these materials are not “soil” and cannot (should not) be handled like soil. Unlike mineral soil (field soil) that can be stored anywhere for any length of time and moved with any heavy equipment, soilless components must be handled as little as possible and with care so they maintain their inherent physical structures and properties.

In the “2018 Growing Media Guide” research report published in Cannabis Business Times’ January issue, 73 percent of survey respondents stated that field soil was used in their growing media in some capacity, while 6 percent said it was their sole material for growing their crops. Many discussion points could be addressed in detail regarding the choice to use field soil in container production. While it may be cheap and easily available, it does offer potential barriers, issues and even missed opportunities.

Issues may include the material weight (which could present lifting difficulties for your employees), introduction of weeds or disease if not properly sterilized, challenging irrigation management, variable soil types and lessened root growth (compared to soilless culture). Missed opportunities may include the inability to be “precision growers,” meaning that during a crop production cycle, if there is a need to adjust water or nutrition to the crop quickly to slow or speed up growth, soil does not respond as readily as soilless mixes. One of the marvels of today’s greenhouse and floriculture professionals is their ability to leverage highly technical and precise monitoring and adjusting of crop inputs and environmental parameters that allow them to control plant growth (based on weather conditions, shipping date, size requirements, etc.). One of the main reasons they can do this is because of the engineered soilless substrates they use to grow their crops, which are highly responsive and easily adjusted.

Many questions, misconceptions and unknowns exist regarding the soilless components used in mixes. We caution readers to be careful where they receive their information not only about substrates, but also about all topics related to cannabis production. We highly encourage cultivators to rely on scientific literature whenever possible or consult with professionals whose information comes from science-based research and experience. Among the reasons we encourage this is that we often hear statements such as “perlite is toxic,” “peat is running out,” “coconut coir is local and more sustainable than peat.” (All three of these comments are 100-percent false, by the way.)

When searching information on the internet about a growing topic, I suggest following up your keywords with “PDF” in your search. This will narrow the scope of the information you find to typically more formal, scientific, published, etc., content compared to open forums, small grower or business websites trying to sell something, or online blogs where opinions flow freely, and facts are sometimes elusive. Google Scholar is also a good place to search for this type of content.

Substrate Diagnostics

In the spirit of elucidating those mysteries, let’s look at what makes for a good substrate for cannabis production.

Substrate quality begins at the source: the supplier. We highly encourage cultivators to choose a substrate supplier (there are many to choose from) and build a strong working relationship with them. When looking for a substrate supplier, do your homework and be prepared to ask questions about the products and their production needs. Ask about technical-support offerings in the event that a problem arises and you need assistance. Ask about product performance compared to other products or competitors’ products. Cost is important, of course, but that should not be the sole driving force behind the decision to choose one company or product over another. A higher-priced mix that comes with technical support and experienced grower experts is well worth the extra cost if problems arise or help is needed. As is true in many things in life, you get what you pay for.

Diagnostics & Testing

To help ensure substrate quality and performance—substrate manufacturers and university or independent laboratories offer a broad range of testing options, which give reliable and replicable indications of the performance of container substrates with respect to water, nutrition and physical, chemical and biological properties. Most methodologies used to develop tests for substrates over the past four decades have been adopted and modified from soil science analytical methods.

The tests noted in the sidebar are usually conducted as part of a product’s research and development (R&D), but they can also be conducted on substrates to identify problems that occur during production.

Ideally, someone at every growing operation should be responsible for checking every load of substrate that is delivered to ensure quality and consistency. If one person holds this responsibility, it improves the chances of catching inconsistencies and being confident that the substrates are correct. A visual inspection of the product should be conducted (not every bale/bag, but spot checking a few) to make sure it looks as it should (as it always has in the past). It can be helpful to keep a sample of “good substrate” from a previous delivery and use it to compare to future shipments for visual consistency. It is also vital that a few samples be taken and checked for pH and EC before crops are planted in the mix. These simple steps do not require much time (typically seconds to just a few minutes), but can offer grower confidence in product quality.

If problems or inconsistencies do occur, growers should contact their substrate suppliers for a technical consultation. This is one of the advantages of buying premixed substrates from suppliers: They have technical support that can help if problems arise. Growers who choose to make or blend their own mixes may have to find experts elsewhere to assist with the problems.

Laboratories, Research & Cannabis

Numerous professional laboratories across the country can be used for diagnostic testing of the substrate itself. A simple online search of “growing media analysis laboratory” will yield many results. Many universities have analytical labs as do many states in the U.S. through their Departments of Agriculture. Several independent labs are also available including PAT2H Horticultural Research Services, JR Peters Lab, MMI Labs and Waypoint Analytical.

Current and future understanding of cannabis-substrate interactions will increase drastically as more state (and private) institutions are legally permitted to research and study these crops.

Accurate and replicable grower trials and experimentation will also continue to provide reliable information about containerized cannabis production. Research does not have to be conducted in a laboratory. The perfect balance of science and application exists in grower and researcher partnerships, which has been the key to success for numerous other horticultural industries.