An alternative to building a new greenhouse for cannabis cultivation is to retrofit or upgrade an existing greenhouse—whether one formerly used for another crop or a cannabis greenhouse in need of improvements. As we know, cannabis cultivation has slightly different requirements than produce or flowers. (Certain insecticides/pesticides and fungicides, for example, can be used on produce and flowers, but are not safe for cannabis.) For this reason, updates are required to convert an older produce- or flower-producing greenhouse to a cannabis-producing greenhouse.

Here are 12 tips for retrofitting or upgrading an existing greenhouse. Remember: These are only some of the important considerations. Each greenhouse and situation is slightly different and will have unique nuances that require further research.

1. Covering: Every form of covering has an optimum lifespan after which light penetration, spectrum and diffusion can degrade and become inefficient. Some coverings not designed for cannabis production inhibit UVB transmission, which, in turn, inhibits THC production. Therefore, it’s important to investigate which type of covering is on an existing greenhouse, its age, when it is scheduled for replacement and if it is suitable for cannabis production.

2. Sealing: All possible entry points (i.e., doors, cracks, joints) must be hermetically sealed to prevent pest and disease entry. Again, produce and flower producers can utilize insecticides and fungicides that cannabis producers can’t, meaning a former produce or flower greenhouse might not be adequately sealed for cannabis production. An easy way to test whether a greenhouse is sealed is to fill it with colored smoke (not generated by fire, but rather smoke grenades); then pressurize the greenhouse using the ventilation system and observe where smoke escapes.

3. Ventilation: In a greenhouse, it is best to have upgraded ventilation, air filtration and sterilization, as well as the ability to create a positive air pressure. Most existing greenhouse ventilation systems will require an upgrade to modern, efficient equipment. When retrofitting, consider installing roof vents to aid in the elimination of unwanted heat and humidity via positive pressure. An efficient greenhouse has a positively pressurized environment and incorporates air filtration, sterilization and air-diffusing capabilities so that fresh air dispersion is possible. With roof-venting capabilities, the positive pressure also aids in preventing pests or disease from entering the greenhouse.

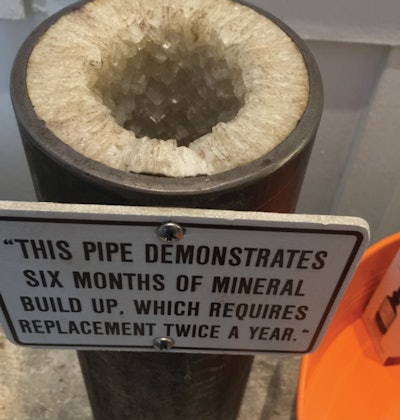

4. Plumbing: Inspect all plumbing for your facility’s water source, and upgrade the plumbing if necessary. Scale and other unwanted minerals can accumulate in older plumbing, adversely affecting water flow (i.e., gallons per hour (GPH)) and plant health. Different water sources have varying water composition, depending on the source or geographic location. A build-up of certain elements in plumbing can cause adverse nutrient effects and fluctuate the pH. Well water, for example, can have a high mineral content, as well as potential risks (such as pathogens and contaminants) that can adversely affect the plant and consumer. Always examine the water source by sending a sample to a lab for analysis. At a minimum, your incoming water source should have the ability to be filtered and sterilized.

5. Irrigation Replacement: Replacing all existing irrigation will usually be required, as drippers may not distribute at the correct GPH rate. Replacing irrigation lines should be considered regular maintenance as needed or as recommended by the manufacturer. Drip irrigation systems also require cleaning and sterilization between each and every crop rotation. This should be incorporated into every standard operating procedure (SOP).

6. Sterilization and Disinfection: Sterilization and disinfection of every aspect of the facility and grow environments is important when starting cultivation in any new or retrofitted greenhouse, and it should be incorporated into every SOP. Give yourself every possible advantage, by beginning with and maintaining cleanliness.

7. Benches and Tables: Most existing greenhouses have outdated benches, or pots are simply placed on the ground. Older, inefficient benches (i.e., dirty, bent or broken) will typically need to be upgraded or replaced. New equipment usually requires less labor for maintenance. Rolling benches that create a roving aisle are often preferred because they offer superior efficiency in many respects, mainly by eliminating dedicated aisles that reduce usable floor space.

8. Floors: Disinfection and sealing of all greenhouse floor surfaces minimizes the possibility of algae, mold or disease outbreaks. Some chemicals that were applied to prior crops could still linger, potentially causing problems when finished cannabis is tested for cleanliness and contamination. Always better safe than sorry.

9. Security: Typically, an existing greenhouse won’t have adequate security. The incorporation of all legally required security measures must be considered. Besides those legal requirements, you must go above and beyond to minimize product theft, focus on employee safety and eliminate the possibility of robberies. (For more on cultivation operation security, see the feature on page 32.)

10. Electronic Monitoring: Some existing greenhouses do not have modern electronics or the monitors required to produce safe, uninfected, commercial cannabis. They often have outdated equipment, environmental controls and monitoring devices, all of which are unacceptable for today’s cannabis cultivator. Incorporating modern equipment and controls can significantly increase efficiency and the ability to compete in a competitive market. Besides efficacy, modern equipment also gives more control over crops and their growth environments.

11. Shade Covering/Heat-Trapping Curtains: Shade cloths and heat-trapping curtains require periodic replacement. The associated mechanisms require maintenance at the very least, or may require complete replacement and upgrade. These shade cloths come in different shading-capability percentages, depending on needs and geographic locations, and aid in minimizing leaf-surface temperatures on hot days. Heat-trapping curtains can be employed in colder locations to aid in minimizing heat loss and heating costs.

12. Blackout Curtains: As with shade curtains, blackout curtains require periodic replacement, as do the associated mechanicals and controls. Systems 10 years or older typically require replacement, serious maintenance or upgrades. Blackout curtains create complete darkness inside the greenhouse in the middle of the day. If there are rips or tears in the curtains, they are counterproductive. If one area of the greenhouse fails to close at the specified time due to a mechanical breakdown, the photoperiod and flowering cycle are both interrupted, which will affect production results.

Again, these are only some important elements to consider when retrofitting or upgrading a greenhouse. Sometimes the usefulness of an existing greenhouse, as well as zoning regulations, dictate that you utilize an existing structure. But it’s important to note that if every issue listed here needs to be addressed in a prospective greenhouse, then the greenhouse has likely outlived its usefulness.