Though the United States Department of Agriculture’s (USDA) final rule on hemp will go into effect March 22, growers will have well over a year and a half longer before they are required to send their plant material to a Drug Enforcement Administration (DEA)-registered lab.

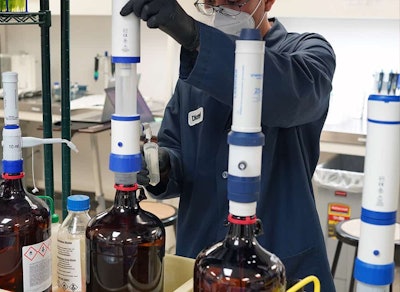

Insights From a Hemp and Cannabis Testing Lab

Dr. Josh Swider, Ph.D., CEO and co-founder at Infinite Chemical Analysis Labs (InfiniteCAL), said he and his company are currently applying for DEA registration, which will be required in December 2022.

He said he thinks the delay was necessary, adding, “We’ve got to remember, … for the DEA to take that many applications, they're going to end up getting a lot of applications at once.”

In their applications, InfiniteCAL and other labs will need to provide the DEA with diagrams of their facilities, as well as information about their security processes and standard operating procedures (SOPs), Swider said.

Although InfiniteCAL will need to change some of the language it uses to address its processes and procedures, Swider said much of what the company is already doing falls under DEA compliance. Still, Swider has been working on the application for months, dotting his i's and crossing his t’s. “It’s not a trivial task or an easy or cheap thing to do,” he said. But, he said, “it’s definitely something doable.”

“Other things that they’re looking at—a lot of it is just, like, how our company is structured and how we’re going to make sure that our samples in-house are not going to get out to the public,” Swider said. “We’re making sure everything’s secure, and also making sure that [we’re] hiring the right employees, so [conducting] background checks….” InfiniteCAL is also ISO/IEC 17025-accredited.

The USDA “strongly encourages” ISO/IEC 17025 accreditation but will not require it. According to iso.org, “ISO/IEC 17025 enables laboratories to demonstrate that they operate competently and generate valid results, thereby promoting confidence in their work both nationally and around the world.”

In 2016, Swider founded InfiniteCAL with fellow chemist and Chief Scientific Officer Dr. David Marelius, Ph.D. The company tests both hemp and state-licensed cannabis in a more than 16,000-square-foot location in San Diego and an 8,000-square-foot facility in Jackson, Mich. Between the two locations, InfiniteCAL runs through about 1,000 potency samples every day.

Shortly after they founded InfiniteCAL, Swider and Marelius tried to obtain DEA registration, but Swider said they were turned away because they also test high-tetrahydrocannabinol (THC) cannabis, which is still a Schedule I drug on the federal level. “But,” he said, “a lot’s changed in six years.”

Now, in an era during which cannabidiol (CBD) is prevalent, Swider said some processors of the popular cannabinoid may be facing an uphill battle. “Hemp processors should be concerned that the DEA will attempt to monitor in-process hemp extract,” he said, adding of the legal THC limit: “It's very unlikely to concentrate the CBD from a hemp plant without exceeding a 0.3% THC result in the process.”

RELATED: Extraction Explained: What Happens to In-Process Hemp Products?

He continued: “If during the process of making a concentrate the sample becomes ‘hot,’ then a company would need to be a DEA-registered entity just like the testing labs. It would be an extreme hurdle for companies to overcome, especially for the smaller mom-and-pop or boutique brands, if they were forced to pay for special permits to produce the materials necessary to make quality hemp products.”

Testing regulations differ by locale. Swider points out that federal agencies do not presently require safety testing for contaminants such as pesticides, microbials, mycotoxins, vitamin E acetate and foreign material, but some states do require them for hemp and cannabis, and InfiniteCAL offers these tests. The costs also vary, Swider added; testing for hundreds of pesticides, for example, is “extremely high compared to just doing a potency test.”

Swider anticipates that these safety tests will become required by the federal government in the next couple of years.

Grower Thoughts on the DEA Lab Registration Requirement and Delay

Hemp growers are keeping an eye on the registration requirement and delay to ensure they’re compliant through 2022 and beyond.

Tweedle Farms, a cannabinoid hemp grower in Jewell, Ore., has about 10 acres of outdoor production, 6,000 square feet of greenhouse production and 1,000 square feet of greenhouse propagation. The team creates custom formulations for products such as tinctures, edibles and topicals—which partners extract—and processes its own smokable flower. The company sells all of the products through its website.

Jason Evans, who co-founded Tweedle Farms with co-owner James Green in 2016, said the business has always strived to follow all regulations and will continue to do so.

"I would like to point out that with the 2014 and 2018 farm bills defining hemp and de-scheduling hemp, there would be, theoretically, no need for any DEA involvement because it’s not a scheduled substance,” Evans said. “Now, because it’s still cannabis and has the potential to grow into a controlled substance, I can see where the DEA would want to insert itself and keep itself inserted.”

Evans applauds the delay in the requirement that labs be registered with the DEA, citing the lack of labs that currently have such registration. Oregon is one of numerous states with no DEA-registered labs, according to a USDA database.

“I appreciate the fact that both the USDA and the DEA have recognized that making this DEA certification requirement would create an incredible bottleneck and would grind the industry to a halt from a testing perspective, which would have the effect of driving everyone, ultimately, into the black market,” Evans said.

Tweedle Farms works with Green Leaf Lab, an ISO/EC 17025-accredited testing lab with facilities in Portland, Ore. and Sacramento, Calif.

“They’re one of the most highly respected labs in the nation, so I don't foresee any hitch in the giddy-up other than the DEA being slow to respond to applications, which I'm sure they're overloaded with now because we've got 49 out of 50 states with active hemp programs now,” Evans said. (Idaho is the last state holding out on developing a hemp program.)

RELATED: Idaho One Step Closer to Hemp Legalization

EcoGen Biosciences, a grower, processor and extractor of cannabinoid hemp headquartered in Grand Junction, Colo., operates as a wholly owned subsidiary of Newport Beach, Calif.-based Kadenwood. EcoGen runs about 80,000 square feet of greenhouse production space in Palisade, Colo.; a 400-acre farm in Mack, Colo., with another roughly 80,000 square feet of hoop houses; and a processing and extraction facility in Delta, Colo., next to 170 acres of farmland. It sells its product into Kadenwood’s branded lines and separate supply chains around the globe.

Offering his thoughts on the DEA lab registration requirement, Garrett Bain, president of EcoGen, said, “It's pretty clear that that's part of the package for the USDA.”

“Analytical testing has been one area that has been a real challenge for a lot of the processors and the growers because [it hasn’t] been very consistent,” Bain said. “I think the methodology has progressed significantly over the past several years, but we need to get to a point where we're all working off the same playbook, where the methodology and the accreditations are standardized and everyone can expect a reasonable result, whether you go to one lab or another. It shouldn't differ.”

EcoGen has its own lab that it uses to test product internally before sending it off for third-party testing, Bain said. The company is working toward ISO accreditation for the lab. Although Bain said he is “not an analytical lab expert by any stretch," he said that for labs that are ISO-accredited, “a lot of that structure should be in place if you are operating at that level. You’ll have the documentation, systems; you'll have the methodologies. You’ll have the pathway to get to that DEA requirement.”

EcoGen works with several labs, Bain said. “We generally like to send samples to a few different folks now and again, in order to maintain our confidence in the accuracy that we’re receiving. Occasionally, we'll send a sample out to three labs and get the results back from all three and compare that to ensure that we can triangulate quality."

Editor's note: This story has been updated to reflect the size of InfiniteCAL's San Diego facility.