With the rapid advancement of container-grown cannabis crops in controlled environments, cultivators often have many questions and perceptions relating to growing media (substrates). Understanding substrates’ role, value and significance in a production system is important for crop health and a grower’s bottom line.

Hundreds of materials have been evaluated over decades, but few are sufficient, economical, abundant and reliable enough to be considered viable options for growing cannabis. Materials that are well-suited for cannabis production fall into two buckets: organic and inorganic. Organic components (peat, coir, wood, bark, composts, biochar, etc.) are classified as materials derived from natural organic matter (carbonaceous in nature). Inorganic components can be classified as natural, unmodified materials (sand, tuff, pumice) and processed materials (stone/rockwool, perlite, vermiculite, expanded clay, etc.).

Some Common Organics…

Peat: For more than 60 years, peat moss has been and continues to be the backbone of horticultural (and cannabis) crop production. Peats were formed by the slow decomposition of mosses and moss-like plants (Sphagnum, Carex, Hypnum, etc.) in wet, acidic environments over the course of many centuries. Large peat deposits are located through northern Europe, Russia and Canada.

Many peat types and sizes/fractions are available in the United States, supplied by Canadian and Michigan producers (mostly Sphagnum peat), as well as some from Florida (reed/sedge peat). European peat producers also sell products in the U.S. and offer different peat fractions than the Canadians.

Properties:

Overall, peat is known to have:

- high porosity

- high water-holding capacity

- low pH and electrical conductivity (EC)

- high cation-exchange capacity (CEC), which is the nutrient-holding capacity of cationic (positively charged) nutrients

- high pH buffering capacity.

Peat is also free from pathogens and relatively stable. It is typically not suitable for re-use.

Disposal issues: None. (No regulatory/environmental issues of peat disposal (either in landfills, land applications, re-use in other products or systems, etc.) exist.)

Note: There is much debate about peat’s sustainability and the harvesting of peat bogs. One claim is that peat is not being replaced as quickly as it is being harvested, causing a peat shortage. These claims are misleading and mostly proven false by many scientific papers over the decades. Specifically, the Canadian peat producers only have open/ongoing harvesting on a small fraction of the total virgin peat bogs in all of Canada. (More information on these peatlands can be found at bit.ly/peatland-statistics-2015.) Environmental stewardship is a priority for peat producers, and natural resource management and restoration practices, including rewetting and layer-transfer techniques, tree and berry plantation, marsh creation and more, are an integral part of what they do.

Coconut Fiber/Coir Coir is the name of the fibrous material that makes up a coconut’s (Cocos nucifera) thick shell. The coconut’s shell/husk contains about 75-percent fiber and 25-percent fine material, which is the so-called “coir pith.” Coconut coir is predominately produced and supplied from Sri Lanka, India, Vietnam, Philippines and Côte d’Ivoire. Limited production closer to the U.S. can be found in Mexico and Costa Rica, but this makes up a small portion of the commercially available coir products on the market today.

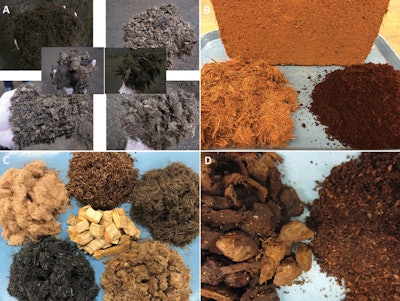

Coir’s chemical properties (sodium, chloride and/or potassium concentrations) can vary substantially. This comprises the majority of concerns with using these products. Processed coir is compressed in blocks for shipping and storage and must be moistened and fluffed before blending with other materials to create a substrate. (See “B” above.)

Properties:

Coir has:

- variable pH (depending on source) of 4.8 to 6.8

- variable EC (also depending on source and amount of washing)

- high CEC (comparable to peat’s)

- high water retention

- inherent high hydrophilicity (water-loving quality).

Coir products typically aren’t reused.

Disposal issues: None

Wood Fiber One of the newer substrate components available for growers, wood fiber and chip materials are gaining interest among plant producers. Research on wood substrate materials in the U.S. began in 2004; however, the introduction and use of wood materials in Europe began in the late 1970s. Several companies in the U.S. currently offer substrates with wood fiber additions/percentages. (See “C” in above image.) Wood fiber substrates in the U.S. are predominately made from loblolly pine (Pinus taeda), a native tree species with more than 30 million acres currently within managed production.

Wood can be engineered into various particle sizes and shapes that make different components for substrates.

Properties:

Wood has:

- an inherently high pH in the range of 4.5 to 6.0

- high porosity

- low bulk density

- low CEC

- low pH buffering capacity

- resistance to degradation for crops less than six to eight months in production

- good drainage and hydraulic properties.

Limited information exists about cannabis production in wood-based substrates, but it is being trialed by some growers.

Disposal issues: None

Bark Processed predominately from pine (Pinus sp.) or Douglas fir (Pseudotsuga menziesii), bark is used in professional mixes and in retail consumer products. The Pacific Northwest (Oregon and Washington) and the southeastern U.S. have vast forest resources from which the bark is often a by-product or waste product of the forestry industry.

Bark is processed, handled, aged and fractioned/engineered in many ways, and it is offered in a variety of sizes and grades/types. (See “D” above.) Bark will be cheaper than peat and coir—a selling point for some growers. The composition of bark varies according to species, growth conditions, tree age and even the time of the year trees were harvested.

Properties:

In general, aged pine bark in the U.S. will have:

- a pH range of 4.0 to 4.5

- a low EC

- a moderately high CEC compared to peat or composts.

The physical properties of bark will vary greatly based on the materials’ particle fraction. It is important to find a reputable and reliable supplier to assure that the quality and consistency remain high.

Disposal issues: None

Other organics Two other materials that have been reported in cannabis production are compost (including vermicompost) and biochar products.

The quality and consistency of compost depends heavily on many factors including:

- type of organic materials being composted

- size of compost piles

- how regularly the piles are turned

- how much air/water they receive

- how long they are composted

- if the piles are covered or uncovered outdoors.

These and other variables make it difficult to produce a commercial product that has the same chemical and physical properties each time (across all seasons of the year, across manufacturers, etc.).

Biochar can be made from three different processes (pyrolysis, gasification and torrefaction). Biochar products can vary based on:

- the feedstock material used (hundreds have been researched)

- temperature of system charring the material

- residency time in the charring process

- moisture content of the material being charred

- particle size of the materials, etc.

Some Common Inorganics

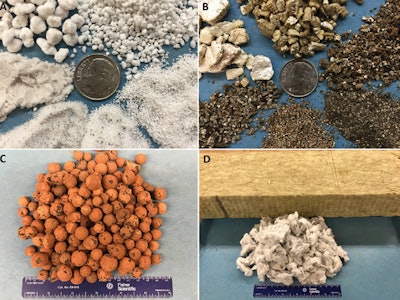

Perlite The most common aggregate used in soilless mixes for more than a half century, perlite originates from volcanic rock, roughly 70 percent of which is found along the Aegean coast near Greece and Turkey. (See “A” above.) Limited deposits also exist in the western U.S. The commercial product is produced by heating the mined rock/ore (after grinding and sieving) to 8000C to 1,1000C (1,4700F to 2,0100F). The natural ore contains about 3-percent moisture, which causes the rock to pop like popcorn and form into the material with which we are familiar.

Properties:

- comes in several grades

- lightweight

- considered sterile

- high porosity

- holds up to four times its weight in water

- a neutral pH (7.0 to 7.5)

- low to no EC or CEC.

Despite some public perceptions, perlite is non-toxic (to humans and plants). Perlite is not without its issues, however. It is the second most expensive component in growing media (retail or professional mixes). It is also dusty, which can be a nuisance to blenders working with it. Lastly, the particle size of perlite in bags or super sacs can vary, leading to inconsistent physical properties in substrates after blending. For these reasons, many alternative aggregate materials have been investigated over the years.

Perlite, however, has long-term stability, can be re-used in multiple cropping systems after steaming/sterilization and is nontoxic.

Disposal issues: None

Vermiculite is produced from a natural clay mineral that contains structural layers that, when mined and heated to more than 1,0000C (1,8000F), cause expansion to create the soft/spongy end-product used in substrates. Vermiculite can be sourced from the U.S.

It is available in many grades (sizes), is lightweight and has a high porosity. (See “B” above.) Often used in seedling germination and propagation, vermiculite has also been used historically in soilless container blends to aid in water and nutrient retention.

Properties:

These materials:

- can hold three to four times their weight in water

- are considered sterile

- have a neutral pH (7.0 to 7.5)

- have low EC.

Vermiculite is most known for its high CEC and buffering capacity for pH and nutrients. The relatively high cost of vermiculite has led many growers and commercial substrate manufacturers to stop using it, at least in high percentages. Vermiculite cannot be steam-sterilized for reuse (the heat destroys it), nor does it have the stability for long-term use.

Disposal issues: None

(It should be noted that rumors of vermiculite containing asbestos were once true, but today’s materials are properly mined from clean/safe mines, and the products are considered safe.)

Baked/Expanded Clay Various sizes and types of clay pebbles have become available on the market since their creation and introduction into the horticultural world in the 1930s. (See “C” above.) They’re produced in North America by forming clay (specific types with specific mineral/salt content and properties) into pellets and firing them in kilns at temperatures around 1,2000C (2,2000F). Clay pebbles are commonly found in hydroponic and in container substrate blends for cannabis production.

These materials are very stable (do not break down easily over time or after several intensive cropping systems) and are viable components in larger containers and long-term cropping systems.

Properties:

Chemically speaking, these materials have:

- a neutral pH

- low to no CEC (or buffering capacity)

- low EC (assuming the clay source was low in salts).

Disposal issues: None

Rock and Mineral Wool Different kinds of mineral wools are available (many made in the U.S.) and are named based on their starting components. Rockwool is made from basaltic rock melted at a temperature of more than 1,5000C (2,7000F). Mineral wools are alumina-silicates that are spun into fibers and contain some calcium and magnesium. The fibrous wools are manufactured when the molten mixture of rock and slag, coke, carbonate of lime and other ingredients is fed onto a rotating drum, which spins the molten mass into fibers.

Properties:

- typical total porosity around 95 percent (meaning only 5 percent of volume is the solid fibers) when used alone

- a pH around 8.0 to 9.0.

Wools are available in slab form for the culture of hydroponic crops or in granulated loose forms suitable for use alone or in combination with other components to form a substrate for potted crops. (See “D” above.)

Disposal issues: Disposal of used wools can be troublesome based on the inability to return these materials (and the chemical binders often used in them) back to nature. Be aware and informed about proper disposal options in your state/location.