Crude extract is exactly that: crude. As an unprocessed material, it must be refined into a specific, desirable form—similar to how the petrochemical industry refines crude oil into petroleum jelly, kerosene, gasoline, diesel fuel, aviation fuel and hundreds of chemicals, among other forms.

Crude cannabis extracts are the result of basic extraction methodologies—be it ethanol or CO2 extraction. Further refinement is usually dictated by the desired end product. For example, a vape pen cartridge has slightly different extraction requirements than an edible. A cartridge may require an extract that has been completely refined to the point that all flavonoids (including pigments) have been filtered or distilled out, resulting in a colorless (clear) extract. An edible may not require use of a clear extract; therefore, some colorants (i.e., pigments and/or flavonoids) can remain, and the extract may require less filtering or refinement.

Filtration

Filtration techniques have recently evolved, and some extraction companies offer remediation services for extracts and/or distillates that would otherwise not meet testing standards. An example is the removal of contaminants (e.g., fungicides). Filtration comes in many forms, but no matter the method, the first step is usually to winterize the extract, which involves dissolving the CO2 extract in ethanol or a similar solvent. This results in a cannabinoid-rich ethanol slurry. The cannabinoid-rich ethanol then is subjected to sub-zero temperatures to freeze fats, waxes, flavonoids and other undesirable compounds by solidifying and coagulating them, so that they can be filtered out via multiple methods. These filtration methods range from using a Buchner Funnel (a funnel with a perforated disc to filter out impurities) to the utilization of different-sized particulate filters (screen filtration).

Some advanced manufacturers mitigate this step by utilizing in-line, de-waxing apparatuses. Many hydrocarbon extractors utilize in-line de-waxers as well to avoid introducing ethanol that will eventually need to be removed to their extracts. Adding ethanol also changes the extract’s composition and increases production costs.

Purification

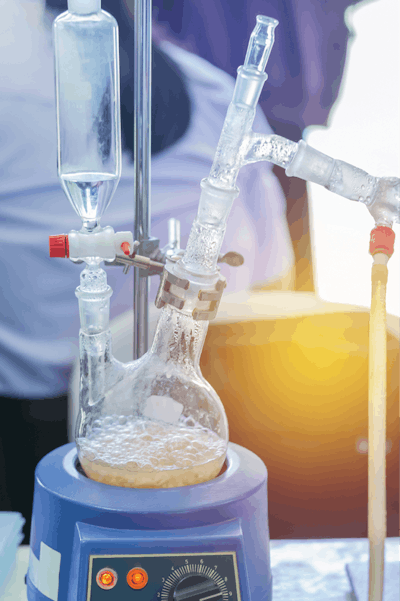

After winterization and/or filtration (if necessary), any remaining ethanol must be removed from the extract. The most common ethanol removal method is to utilize a rotary evaporator, which heats the cannabinoids and ethanol in a vessel under vacuum from a vacuum pump. The heated ethanol evaporates and is collected by a condenser, leaving ethanol-free, concentrated extract in the vessel. At this point, the extract is ready to be used as-is for certain products that do not require further refinement, such as Rick Simpson Oil (RSO).

Multiple options exist to further purify and refine the extract, should it be necessary. For example, some hydrocarbon extractors also utilize distillation when they are using trim, or lower-quality cannabis buds, to extract. In this case, even though the product may be cannabinoid-rich, the extract may have excessive fats/waxes and exhibit a darker color. This is a less desirable product. But it can be refined further via distillation to eliminate those undesirable qualities and produce a cleaner concentrate.

Distillation methods range from short-path distillation, wiped-film distillation, falling-film and thin-film distillation, as well as other, yet-to-be-adapted methods not commonly used by most current cannabis extractors, but that will soon become more relevant as production sizes increase.

The distillation process allows processors to further separate available cannabinoids, which yield purified compounds, such as CBD and THC exceeding 95-percent purity. The same principle would also separate other available cannabinoids such as Delta-8, THC-V and a host of others if present en masse. Distillation allows a processor to target specific boiling point temperatures of the available cannabinoids, resulting in purified cannabis compounds that can then be formulated into the final desired forms.

Distilled Innovation

As production increases, equipment manufacturers will evolve. Already, hydrocarbon, ethanol and CO2 equipment manufacturers are rapidly scaling up their apparatuses (or completely re-engineering them to handle much higher capacities) and innovating large-scale automated systems that minimize production time and labor, thus lowering overall production costs.

Some companies utilize technologies common in industrial applications, such as spinning band distillation (SBD), which is used to refine fish oil on an industrial scale. Technologies such as these will ultimately migrate into cannabis extraction refinement companies. Petrochemical companies and many other chemical manufacturers, as well as flavor and fragrance industries, employ equipment and methodologies that will carry over into the cannabis space as well.

In the future, production costs will factor into what is considered crude extract. Crude will be considered cannabinoids and terpenes that have been separated from the biomass (the green vegetative plant material) through fresh-freezing. The reclaimed material is kief (aka resin gland heads) and it is the most desirable component of cannabis as it contains the active ingredients (cannabinoids and terpenes). The resin gland heads will then be dissolved into ethanol for winterization, filtration and distillation; made into rosin form via heat and pressure; or further refined by utilizing CO2 or hydrocarbon extraction methods. Because extractors buy their extraction material by weight, removing the plant biomass before extractors purchase the product (i.e., separating the resin gland heads from the plant material) concentrates the amount of active ingredients available by weight, increases output capabilities and lowers production costs—enabling a concentrate company to provide final products without compromising quality. Superior quality at a superior price usually wins.

As we move into the future, manufacturers will continue to investigate other methodologies. For example, will it be possible to squeeze active ingredients out of large amounts of cannabis? While industrial-scale hydraulic presses that would be required for this process are expensive, and most do not have heating capabilities, I believe this form of extraction will be investigated thoroughly, especially when considering the possibilities of pressing 100 pounds of kief. If a manufacturer desires only cannabinoids and not to preserve terpenes, then pressing the cannabinoids out of kief with heat would be perfectly acceptable and an economical extraction method—that is, if it can be accomplished en masse.

In California, separating active ingredients has other serious implications that must be considered by both growers and extraction companies. In the Golden State, cannabis is taxed by product weight. Eliminating the green vegetative material and concentrating the active ingredients minimizes the taxable material’s weight, in that taxes paid on 1 gram of bud would be the same as 1 gram of kief, yet with kief, the available percentage of those desirable compounds is much higher.

Separating biomass from active ingredients prior to selling product to an extraction company or conducting in-house extraction has numerous benefits. It is advantageous for extraction companies to simply purchase and refine raw resin, whether it is from fresh-frozen material, dry material, bud or trim. A friend once said to me, “But nobody wants to buy kief.” That may be true—the consumer may not; but eliminating the biomass and paying taxes only on weight sold can dictate success or failure for some companies. The same friend then pointed out kief’s low market price today, to which I replied, “Soon, the industry will adapt and price kief and other crude forms by percentage of available cannabinoids and terpenes, and producers will ultimately be paid according to the milligrams of cannabinoids and terpenes, because they are, in reality, all that is desired.”