In the heavily regulated and scrutinized cannabis industry, Graham Farrar, founder of Glass House Farms, says it’s important to do better than what’s required. Implementing sustainable practices like a state-of-the art water reclamation system and beneficial insects is important to Farrar and good for the environment, but it’s also good for business.

Glass House Farms operates a cultivation facility in greenhouses once used for orchid and Gerbera daisy production in the Carpinteria Valley in Santa Barbara, Calif., an area with a rich horticultural history and booming agricultural industry, where cannabis, avocados and strawberries are cultivated in the ideal climate and fertile land that’s surrounded by the San Ynez Mountains to the east and the Pacific Ocean to the west.

Glass House is close to opening its second site, a 355,000-square-foot operation which, like the first, will be in repurposed greenhouses and run on a perpetual harvest system, where the team will plant and harvest cannabis continuously. The company is awaiting the county’s final approval, but otherwise, the facility is ready to go. Also in the works is a new retail venture for Farrar, a serial start-up founder. The dispensary is called The Farmacy and will highlight local Santa Barbara brands. In this interview, Farrar explains what it means to be a craft cannabis producer, how he distinguishes his business in one of the largest cannabis and tourism markets in the U.S., and shares future plans and predictions.

Michelle Simakis: How did you get started in cannabis cultivation?

Graham Farrar: I grew up in Santa Barbara, which is where we live now and where both of our farms are, so this is hometown for me. I actually come into this as a tech geek more than an agricultural geek, so I guess I’m an ag-tech geek now. I was one of the original people at Sonos, which is a pretty cool wireless audio system that some people know. It’s a public company now.

After Sonos, I started a company called iStoryTime, which made apps for kids, right when the iPhone first came out, so basically narrated, interactive story books. Then I helped start a company called Elite Garden, which is a [wholesale nutrient] business in the cannabis space. I’ve been a longtime believer, in terms of the societal- and health-, the good-for-the-world-side of cannabis, and had personal grows for years and years. I just think that regulation is a much better approach than prohibition. It’s stupid that we are tearing apart families. Give people access, and they will find ways it benefits them. My line is: if you think you don’t like cannabis, you just don’t know how you like it.

Simakis: Why did you opt to launch Glass House Farms in 2015 in a converted Dutch greenhouse, and what did the industry and California look like at the time?

Farrar: Obviously California’s medical market is [more than 20] years old, and it is still the epicenter for cannabis. We started Elite, which was built on the foundation [that legalization] was going to happen, and it was going to move out of people’s garages and closets and into traditional agriculture. A lot of our customers were in Santa Barbara County because there’s a bunch of really good greenhouse infrastructure here. … And it’s the horticultural fundamentals that drive the good places to grow cannabis because at the end of the day, it’s a flower. [Santa Barbara has] greenhouses, water, good climate, labor and accessibility to big markets. We’re an hour and a half from LA, right off the 101 (Pacific Coast Highway), right next to the ocean. It’s a great climate. And so we basically got an introduction to the forefront of professional agriculture for cannabis.

Simakis: How has the California cannabis consumer changed over the past two decades, and how do you set yourself apart from other cultivators?

Farrar: With the new consumer coming in, they look at the product, the price and the value in the brand ethos and all of that. The 2.0 consumer I think is vastly different than the historical cannabis consumer, [who would] go to a doctor, tell them they have a hard time sleeping or whatever was bothering them and get a medical recommendation, [then] end up going to a dispensary that often feels a bit like an adult bookstore.

There’s [about 40] million people [in California,] ... and [hundreds of] millions of tourists. And if they’re 21, they’re going to walk into a dispensary—and 99 percent of them have never been to a dispensary before—and so they’re going to walk into this whole plethora of products, and they’re not going to say, show me indoor-[grown], because they don’t even know what that means. My wife wouldn’t pick the tomato grown inside. She’s going to say, give me that sun-grown one. And I think that a lot of these consumers are as well, which is the market that we go after.

This is kind of a tangent, but I won one of three [adult-use] dispensary permits in the city of Santa Barbara. Our shop is called The Farmacy, and we’re about 30 days away from opening.

Simakis: Will you only sell product that you grow and produce, or will you have a mix of different brands?

Farrar: We will highlight our brands and really all of the Santa Barbara brands. We’re going to have a whole local section. We’ll be kind of like a wine store where they might have wines by region. But the goal is to be the best dispensary it can be, not be a marketing arm of our farm. We’ll certainly highlight it, but we’re not going to only have [our products].

Simakis: You mentioned highlighting local products, and you emphasize on your website the fact that you are from Santa Barbara County and that you are producing “craft cannabis.” Why is that important to you and what does “craft” mean to you?

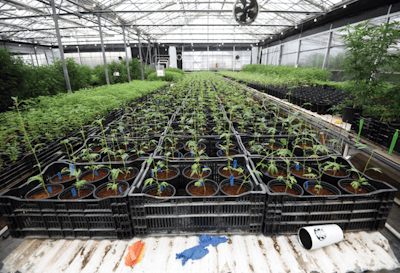

Farrar: We’re going through an interesting transition, right? To me, craft cannabis means we love the plants and the people who work at the farm. [In traditional agriculture], there is a lot of seasonal labor and part-time workers, and you hire them when you need them, and as soon as you’re done, you send them home. We’ve got a set up where we’re on this continual harvest, so our team is always doing all segments—planting, harvesting, trimming, cloning—they’re always there. Currently, we harvest about every five days, which means we plant every five days, and it means that they’re always drying and trimming. We have a team of people who are all part of a family; they are full-time employees. They have health benefits. We pay more than minimum wage. They have sick days and paid time off. We do employee appreciation lunches once a month. Because they are part of us and our team. That is part of being a craft producer. We’re trying to do it bigger than many people, but we’re not losing touch with the quality that we want to be part of.

Simakis: Thinking about the craft beer industry, “craft” often refers to the size of the operation, as well. You are about to open a second site that is 355,000 sq. ft. Do you have additional plans to expand?

Farrar: There are some people that would look at us and say, “Oh my God, you’re big cannabis,” or “This is so commercial,” or whatever, but the reality is with where [the industry is] going compared to where we started out, we’re going to be craft cannabis. I don’t think there is going to still be these 5,000-square-foot grows. Or if there are, they’re going to be a very niche kind of thing where someone’s doing something really amazing similar to Screaming Eagle Wine. They’ve got a wait list for the few bottles they produce, and they’re sold out before they make them. We feel big now, but we’re going to end up being Lagunitas to Budweiser at some point. And so, that’s what craft means. Quality, consistency, efficiency, but big enough that we can support a California-size market.

The two things I believe in the most, not to discount retail, are supply chain and brands. So, you can’t be a brand if you can’t keep your product on the shelf, and for that you need a consistent supply chain. If you have the supply chain, but no consumer even knows you, then you’re a little bit of a commodity. I’d really like people to know the Glass House brand. And we’re big enough for the supply chain to make sure that when [California has] the 3,000 dispensaries that we should have instead of the [about] 500 that it does now, that we have a big enough supply that every single dispensary can have [our product]. That’s kind of our big goal.

Simakis: In speaking of branding, you’ve been described as an eco-friendly company and emphasize some of your sustainability methods on your website. How did you become known for this?

Farrar: I have two taglines. One is sun-grown indoor, which is because we’ve got these really high-tech greenhouses, the plants are grown under the full natural sun, but at the same time they are grown inside using a precision agriculture approach where we can very precisely control the climate. So it’s the best of both worlds. We are a mile from the ocean, so we get these ocean breezes. It’s a little bit of a stretch, but I call it true ocean grown because the ocean is what makes the climate so great. We use only a very few OMRI-listed products, we use all beneficial insects, which is awesome. We recapture and recycle all of our water.

Simakis: What made you decide to use beneficial insects as part of your overall IPM system?

Farrar: One, because the testing in cannabis is so strict … there are a handful of things that we can’t use, and of course we don’t. And there are things we could use, but we elect not to. I would love to see all of agriculture evolve to do it the way we are doing it where you are working with nature instead of against her. We don’t have to spray and can leave the plants alone.

Simakis: How does your water reclamation system work?

Farrar: We actually are putting in these new ultra-filtration units, which are sterilized kidney dialysis filters, so literally medical-grade filters that they use, and then they can’t be used for people anymore. So they are sterilized, and then we pass our [water] through them. They filter out bacteria and viruses; they take out the pathogens from the water, leave all the nutrients and the water, and we blend it back in and we reuse it until it’s all gone, which is awesome for our water usage and awesome for the environment because we’re not throwing away stuff that still has value.

We’ve always been recapturing our water. We did it before you needed to, and we have a tendency to do [things before they are required]. We were testing before it was required and using our internal track-and-trace system before METRC was required. [Water reclamation] is not technically required, but the reality is there is an immense amount of oversight for cannabis. People vastly underestimate how much regulation there is in the cannabis industry. Cannabis makes organic look dirty.

Simakis: Have you made improvements to this system at your new farm?

Farrar: We have this really cool new system at the new farm where the entire floor is like Gore-Tex at the top, and then engineered layers of sand and then an impermeable membrane at the bottom so you could spray a fire hose on it and it goes down through the Gore-Tex layer. We don’t want humidity in the greenhouse, and the Gore-Tex doesn’t let the humidity come back out through the sand. [Water] collects in the middle, and [then is pulled] out of the greenhouse. And then it goes through the ultra-filtration units and then gets recycled back into the next irrigation cycle.