The U.S. hemp-derived CBD market is expected to reach $23.7 billion by 2023, up from the current value of $5 billion, according to Brightfield Group. Thousands of farmers are ramping up production in response to the passage of the 2018 Farm Bill (which legalized hemp at the federal level), the expansion of state industrial hemp programs and the promise of profits.

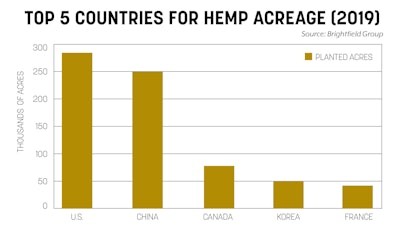

Farmers planted an estimated 288,000 acres of industrial hemp in the U.S. in 2019, up from 78,000 acres in 2018. The U.S., China and Colombia lead global industrial hemp cultivation in 2019 in the number of acres planted, according to Brightfield Group’s upcoming “Hemp Cultivation” report.

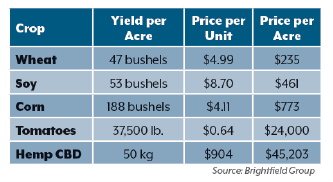

In the U.S., the profit potential of CBD is driving the growth in hemp cultivation, with about 87% of the 288,000 acres expected to be used for hemp-derived CBD processing in 2019. On a per-acre level, hemp for CBD could potentially generate $45,203 in revenue, compared with $773 for corn.

Flexibility and a high risk tolerance are important in hemp farming, as there are multiple challenges in growing hemp for CBD extraction, which include:

Difficulty obtaining certified feminized seeds and clones. Farmers looking for the highest revenue potential desire female hemp plants because CBD levels are highest in unpollinated female plants. Planting female clones ensures all female hemp plants, but the high cost and limited availability has restricted its use. With the shortage of certified feminized hemp seeds, farmers have purchased so-called feminized seeds without guarantees that they will be male-free or high in CBD content.

Labor-intensive crop. There is a lot of manual labor involved in hemp cultivation, especially during the harvesting stage. Because the industrial hemp industry is new in the U.S., options for hemp harvesting machinery are limited, so some farms are retrofitting their machinery to harvest hemp for floral material (where the CBD content is highest in the hemp plant).

Required expertise. Growing hemp for CBD extraction is not a row crop like corn and soybeans. Cultivating hemp for CBD is similar to tobacco and vegetables, with more spacing between plants.

Lack of traditional markets for selling hemp. The result is less price transparency, and companies that are not honoring agreements to buy hemp from farmers.

Risk of a “hot crop.” Industrial hemp crops can fail state agricultural department testing prior to harvest if test results show more than 0.3% THC by dry weight. The farmer is then required to destroy the crop.

Pollen drift issues and cross-pollination risks. CBD levels are highest in unpollinated female hemp flowers, while male hemp plants produce no flower. If male hemp plants, which are grown for fiber and grain, are planted too closely to female plants being grown for CBD, the male hemp plant can pollinate the female plants, leading to lower CBD yields as the plant expends energy for seed production rather than floral production. Similarly, the presence of male hemp plants can reduce the THC content of the female cannabis plant if pollination occurs.

Despite the risks involved with hemp farming, more U.S. farmers are expected to invest in hemp cultivation for the higher return potential from hemp-derived CBD. American farmers can capitalize on the growing demand for U.S.-grown hemp by marketing their CBD brands as “grown in the USA” or “locally sourced.”