Front Range Biosciences is taking cues from traditional agriculture and operating a clean stock program for cannabis, which can help cultivators reduce loss and increase efficiency, according to CEO Jon Vaught.

Lafayette, Colo.-based Front Range Biosciences, now in its second year of operation, has established a clean stock nursery program that uses tissue culture to help clean up, store, mass-produce and certify plants, ensuring they are disease-free and true to type. It also has a research- and development-focused varietal breeding program. Front Range Biosciences has a 2,600-square-foot tissue culture lab and a 12,000-square-foot greenhouse, and works with hemp and marijuana cultivators, as well as coffee farmers.

“We saw a big opportunity in cannabis as a new crop and an opportunity to do something unique in agriculture, and it combines all of these different things that I’ve … been very interested in and have been important in my career—food production, human health and diagnostics, and even drug development and pharmaceuticals, so all of that intersects here with this really fun new crop in cannabis,” Vaught says.

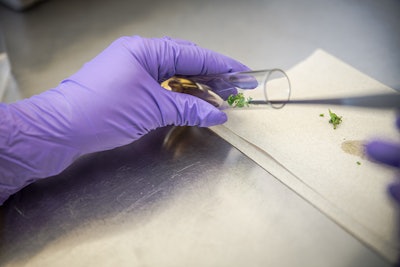

Front Range Biosciences is not reinventing the wheel with its clean stock program, Vaught says, but rather refining programs that have existed in other crops (such as potatoes, sugarcane, hops and ornamental plants) and applying it to cannabis. Tiny pieces of plant material are chopped up in the company’s tissue culture laboratory, and the individual shoots are then turned into more plants, which are cleaned to remove bacterial, fungal and viral pathogens, as well as microscopic pests like mites and aphids. “All of those get removed during that process, so they’re getting cleaned up, if you will, and then we multiply them … and build up inventory of thousands, tens of thousands, even hundreds of thousands or millions in a very small space in the laboratory,” Vaught says. “From there, we get the plants ready for production.”

The plants are also tested for pesticides, he adds. They then go through a process called acclimatization, where they leave the laboratory and enter a greenhouse or an indoor or outdoor production space in preparation for delivery to the customer.

Front Range Biosciences also conducts true-to-type testing. “We take a few plants and … flower that plant out and make sure that it has the characteristics it’s supposed to,” Vaught says. “That way, the growers can feel confident that what they’re getting … is what they say it is.” True-to-type testing can be done in a grower’s facility or in Front Range Biosciences’ facility, he adds.

The company works with growers directly and can work with their genetics, Vaught adds. “We gladly respect the breeding work that has gone into a lot of the genetics that have been created and we consider it intellectual property, and we’re happy to help protect it, so we can work with a grower’s genetics even if they’re exclusive genetics that they have,” he says. “We can produce them exclusively for them, and then also provide them a safe, off-site back-up of their genetics, which is also often extremely valuable, as well.”

Looking ahead on the genetics front, Front Range Biosciences is conducting a research project with the University of California, Davis, to sequence a hemp genome in order to develop specific genomic markers and lay a foundation for growers for breeding and bringing out the best traits.

Cutting Costs and Reducing Losses

Although Front Range Biosciences’ plants may be more expensive upfront, the overall program reduces costs in the long run by cutting operating costs and reducing losses, Vaught says.

By focusing on the nursery part of the supply chain—curating and helping create new genetics and mass-producing those genetics—Front Range Biosciences helps growers feel more confident about the plants they receive and be more efficient in production, Vaught says. “Instead of a grower having to have their own nursery and manage their own mother stock and produce their own clones, they can simply outsource that to us,” he says. “We can maintain their plants off-site in our facility, so … they’re not exposed to any of the production issues that you have in large production greenhouses or indoor environments—any of the pests and pathogens. You’ve got this back-up, safe, secure place where your nursey is.”

The clean stock program also allows cultivators to re-dedicate space used for propagation to growing, which provides them with more product to sell. “In most cannabis growing facilities, if they have their nursery on site, it’s kind of dead space to them,” he says. “They’re using it to feed their production. If they could outsource that, … they could re-dedicate that space to flowering—which per square foot is worth a lot more money to them than having to maintain their own nursery.”

Plants that come out of the clean stock program are of a higher quality, Vaught adds, with more vigorous plant growth in the early stages. “That leads to—if integrated properly with a pest management program at a production level—them starting out with clean, healthy plants that are pest- and pathogen-free,” he says. “It minimizes the inputs required for pesticides and the labor required to maintain that clean, healthy plant.”

The program also provides a reliable supply chain, where cultivators can set up a production order with Front Range Biosciences and schedule production planning very systematically, as well as a reduced risk of disease. “When you start scaling up in agriculture—and this is true in all crops—your risk due to pest or disease outbreak, that risk becomes bigger the larger your scale is,” he says.

Overall, a clean stock program like Front Range Biosciences’ is a way to start strong with cultivation, and when combined with effective growing methods and a strong integrated pest management program, growers can reduce the risk of loss due to pests and disease, Vaught says.

“You’re probably going to see increases in production yields, in your efficiency, across the operation because you can be more focused on what you’re doing,” he says. “Price compression is happening across the board in this industry, and competition is rising very quickly, and we’re going to see more and more of that as legalization continues to spread, so you want to be efficient and you want to be positioned well to survive the ups and downs of the market swings and pricing.”

Photos courtesy of Front Range Biosciences