Any cannabis grower can tell you how much hard work and dedicated care goes into every plant before finished product hits retail shelves. Every single nutrient, tool, technology, and human hand that touches the crop contributes to the quality of the final product—but each of those contributing factors comes at a price.

Controlling production costs is critical for cultivators who want to remain competitive in this industry, especially for those who want to cost-effectively scale production without cutting corners.

“While we are always looking for new ways to reduce our production costs, we’re not willing to sacrifice any quality just to save a few dollars here and there,” says Josh Malman, vice president of cultivation at Jushi Holdings, Inc., a vertically integrated multistate cannabis company based in Florida, with operational cultivation facilities in Nevada, Virginia, and Pennsylvania, and recent acquisitions in Ohio and Massachusetts. “Our No. 1 goal is more efficient production of high-quality flower.”

Although different cultivation methods necessitate different calculations, producers interviewed for this article agree that the primary production expenses fall into three main categories:

- natural resources, including water for irrigation and electricity to power supplemental lights;

- supplies such as nutrients, inputs, and other materials;

- and human capital.

Unlike the fixed costs that contribute to a cannabis company’s overhead (such as licensing fees, facility build-out, rent, taxes, and insurance, which are typically not included in production costs), these three buckets present endless opportunities for growers to cut costs and add efficiencies.

By optimizing these resources, cultivators can control production costs and increase yields without sacrificing quality. Here are some financially savvy strategies that cannabis companies are using to control costs as they scale.

Calculating Cannabis Cultivation Costs

The challenge for cultivators is not only reducing cannabis production costs, but simultaneously increasing crop yields. This balancing act is key to driving production efficiencies that ultimately benefit the bottom line.

“The easiest way to lower production costs is to increase yield,” says Nathan Kelly, chief cultivation officer at Sozo Companies, a vertically integrated cannabis company headquartered in Warren, Michigan, with retail locations in Cheboygan and Muskegon. “There is always low-hanging fruit where we can find ways to do things more efficiently to get a better yield without increasing costs at all.”

_fmt.png?auto=format%2Ccompress&fit=max&q=70&w=400)

Under optimal conditions, most growers aim for production costs of $1 per gram of dried flower, Kelly says. But it’s not just about how much it costs to produce each gram, he says—it’s how many grams you’re producing within a given space. Traditionally, Kelly says, indoor growers relied on the “old-school way” of measuring cannabis yield in terms of pounds per light.

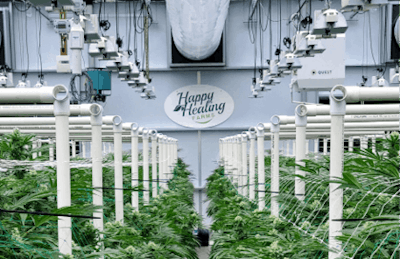

“If you only get a pound per light, you’re basically breaking even. Anything over that is profit,” says Daniel Wright, head grower and manager at Happy Healing Farm, a cannabis cultivation operation in Medford, Oregon, which produces between 0.8 to 1 gram of cannabis per watt of supplemental lighting in its two greenhouse facilities.

“Two pounds per light has been the default industry standard, and there are generally five cycles a year. So you multiply your number of lights by 10 to estimate your yield,” Kelly says. “For a facility that has 1,000 flowering lights, we expect to grow 10,000 pounds a year.”

Kelly noted that the number of cycles can vary depending on the cultivars grown, as some mature in as little as 48 days, while others take as long as 98. Sozo aims for plants that mature in about 63 days.

More recently, Kelly says, the industry’s common measurement of yield has shifted toward a calculation of grams per square foot and, more specifically, grams per square foot of total cannabis canopy. The generally accepted minimum target, according to Kelly, is 60 grams per square foot of canopy.

Conserving Natural Resources

Utility consumption is one of the most pressing cost concerns facing cannabis growers because water, electricity, and natural gas are often key ingredients in cultivation.

“Electrical costs are one of the higher-ticket items for indoor cultivations and greenhouse operations that use tightly controlled systems with supplemental lighting,” says Malman, who manages indoor cultivation across three facilities. “The cost of operating the mechanical equipment is not necessarily overlooked, but is not often understood.”

Understanding these costs requires a long-term perspective, he says. Investing in energy-efficient LED lighting and high-tech mechanical systems adds higher upfront capital expenses, but also reaps long-term rewards in the form of lower utility bills, rebates, and other efficiencies.

For example, Jushi’s LED lighting configuration paved the way for vertical cultivation, allowing Malman to “take advantage of the floor-to-ceiling space to maximize output per square foot.”

Likewise, Kelly leverages LED lighting for Sozo’s indoor cultivation, along with a two-tiered racking system to more than double his canopy space. “Making that decision was the key step to lowering our costs because the LED lights allow us to utilize vertical space more efficiently,” he says. “Although it comes with a higher upfront price tag, LED was also about being more energy-conscious.”

The less power a cultivation space consumes, the more cost-effective the crops become—especially as yields increase. But for some cultivators, energy efficiency isn’t just about reducing the monthly bills, but reducing the strain on limited resources.

“Because of how electrically demanding this crop is, we’ve changed our cultivation techniques to find ways to be more sustainable,” Malman says, noting they are looking to reduce usage of other inputs. “[We are] collecting condensate water from our mechanical units and reusing that for irrigation. In most areas of the country, the cost of water is relatively small, but looking for ways to ‘green up’ our industry is very important.”

"The easiest way to lower production costs

is to increase yield.”

–Nathan Kelly, chief cultivation officer at Sozo Companies

Saving on Supplies

From pre-mixed nutrients to tons of growing media and a bevy of other tools and materials, cultivation supplies can quickly add up in cost. This category comprises nearly a quarter of Sozo’s total production costs, with more than a third of this supply budget going toward nutrients. (See Chart 1 on p. 33)

“Nutrients are widely seen as the highest cost in our industry,” Kelly says. “There are less expensive ways to do it, such as mixing your own salts. We still run a premixed hydro line that we’re very happy with, but we are always exploring options that would save us money.”

Although pre-mixed bottled nutrient solutions traditionally have been the norm for indoor grows that rely on hydroponics or fertigation systems, “you’re seeing more operators realize that you can source the same chemical salt formulation in a much cheaper manner,” Malman says. “Moving to a dry soluble formulation at Jushi brought down our [nutrient] costs 85%.”

To continue trimming input costs, Jushi’s team regularly evaluates new suppliers to find the best deals on nutrients, and even purchases materials in higher volumes to unlock bulk discounts.

Another strategy is simply recycling materials. For example, Happy Healing Farm saves tens of thousands of dollars every year just by reusing its growing media, according to Wright. “Instead of changing out all the soil in our greenhouses, the soil gets tested and then we hand-cast amendments, which are only like $400,” says Wright, who pays attention to heavy pH fluctuations, trace metals, and other minerals in the soil analysis. “We paid $300 a yard for this organic soil, so if we had to refill the greenhouse, it’d be $30,000 worth of soil, plus the labor. We’re reusing as much as we can, and we haven’t had to replace it so far in two years.”

Optimizing Human Capital

Labor costs can be the most stressful component of production because the true value is difficult to define by dollar signs. Beyond payroll, there’s time and hassle involved in hiring and training employees, and other long-term investments are required to retain the good ones.

That’s why Wright says that the key to Happy Healing Farm’s efficiency is his small-but-productive team of three, with occasional support from additional part-time staff. “We’re a really efficient crew because we have really good, experienced people,” says Wright, who works with his wife, Jenni, and one other grower, Eric Lynch, to cultivate about 800 plants in 4,000 square feet of greenhouse space, plus another 700 plants in 20,000 square feet outdoors. “When I worked at another farm, we went through 100 people one season, and there were only two or three really good people—and one of them works for me now. That’s where your efficiency comes in, is paying people who are good at their jobs.”

To supplement his small team post-production, Wright hires a local company to send a mobile crew of trained professionals who provide hand-trimming services for less than $150 per pound. “Instead of [training and] paying people to sit there for weeks on end, they trim everything in a week. You’d be hard-pressed to find enough $15 per hour people to do what they do,” Wright says. “They do a good job, and they’re really efficient, so it works out amazing for us.”

“If you only get a pound per light, you’re basically breaking even. Anything over that is profit.”

–Daniel Wright, head grower and manager at Happy Healing Farm

As cannabis operations scale, these workforce demands can add excessive time and cost to production—forcing many cultivators to consider automation to alleviate labor pressures and enhance productivity. For example, Happy Healing Farm uses an automated fogger to apply organic pest and disease treatments in the greenhouse, instead of sending in an employee to spray manually, which Wright says could take four hours per application.

_fmt.png?auto=format%2Ccompress&fit=max&q=70&w=400)

When it comes to harvesting and post-production, though, some growers believe machines cannot replicate the quality of certain processes, while others have found efficiencies by automating processes like trimming.

“Of course, there’s an ongoing debate about hand-trimming versus machine trim, and I’m not sure we’ll ever see that debate end,” says Ryan Cook, executive vice president of operations at Jushi. “Like any cannabis producer, we were quite reluctant to bring in any equipment to do that level of processing. But the technology has improved over the years to support our efficiency efforts. From packaging to sorting to trimming to rolling, the automation has been designed and purpose-built to retain quality throughout the production process.”

Looking Beyond the Bottom Line

With 55 employees at its cultivation facility (including executives, administrators, and other non-cultivation staff), more than half of Sozo’s total production costs, on average, relate to labor. Employee benefits are “quite a big line item,” Kelly says, because Sozo pays 90% of its employees’ healthcare costs and 80% of their dependents’ medical bills. Although the company could instantly lower production costs by slashing these generous benefits, Kelly says the repercussions of labor decisions go far beyond the bottom line.

“When you invest in employees, you’re going to get that back,” he says. “[By offering] these benefits, hopefully we’re creating a vibe that attracts great quality employees, so we get a talent edge over our competitors. Ultimately, that’s going to bring dividends back to the company.”

“While we are always looking for new ways to reduce our production costs, we’re not willing to sacrifice any quality to save a few dollars here and there,”

– Josh Malman, VP of Cultivation, Jushi Holdings, Inc.

By assessing production costs in terms of long-term gains rather than short-term cuts, cultivators can reallocate resources to increase efficiency and productivity without sacrificing quality.

“We have a corporate responsibility to continuously review and adopt new practices to make sure that we’re operating efficiently,” Cook says. “If we continue to develop processes that bring a high-quality product to market at a lower cost, we can provide a better price point for patients and end-users.”