Comparing water activity (Aw) to moisture content. Understanding the presence of ethylene in cannabis dry/cure rooms. The ways in which freezing (or non-freezing) methods impact terpene composition post-harvest.

Whether your cultivation operation is harvesting multiple times a year, or if this outdoor harvest season has you busier than ever—these drying and curing concepts could be important to the overall quality of your product.

In the research-backed session “Master the Art of Drying and Curing” at Cannabis Conference 2022 (produced by Cannabis Business Times) on Aug. 25 in Las Vegas, Dr. Allison Justice outlined recent studies conducted via Cannabis Research Coalition—a farmer-funded professional group including Justice’s hemp genetics company The Hemp Mine and Dr. Jim Faust’s Flowering Physiology Laboratory at Clemson University—which present findings and pose serious questions about these concepts.

Keep reading for key takeaways and a video link to Justice’s full recorded presentation.

Drying and Curing Desirables

Drying and curing is a way to “change or preserve” what you’re harvesting, Justice said, adding that “to figure out where we’re going, we have to understand, What are those quality metrics we want?”

First, she said it’s important to consider that aesthetics and fragrance of the buds are important at the point of purchase. In other words, the at-purchase or at-consumption visual, aromatic and physical set points for buds. Visual qualities may be frosty and green or purple in color (not moldy or brown). Aromatically, buds shouldn’t smell like freshly cut grass. Physically, they should be firm, dense, and crispy but not wet—all before considering the important cannabinoid and terpene content of specific varietals. Then, when smoked, it should feel smooth, not harsh, and have taste to it.

When it comes plants for more established ornamental flower markets, such as poinsettias and cut roses, there are long-established studies and practices outlining precisely how the plants should be preserved depending on their next step in the supply chain. But those parameters aren’t yet set for cannabis—a dried flower meant to be smoked, no less, she said.

Moisture and Water Activity (Aw)

The most important reason for drying cannabis is consumer safety, Justice said. “There’s a lot more to it, but in short, if you have a plant that’s covered in mold, or has things that are not human-healthy, you have a bad product,” she said, adding that step one is removing the right amount of water to preserve it.

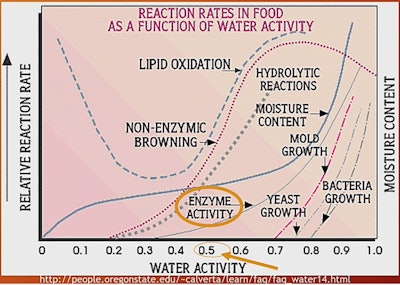

“If you look at the food industry or food science, you’re not looking at water content because if you think about a raisin, it’s mushy still—there’s still some moisture in there, but it’s at a low enough percent where there cannot be microbial growth,” she said. “So a better way to measure—and this is what a lot of folks are going to in the cannabis industry—is water activity, instead of moisture content.”

Moisture content is simply the total amount of water in a fruit, flower, etc., whereas water activity (Aw) provides a measure of available water for microbes to grow.

Justice shared the below chart from Oregon State University (though it is no longer on their website, she said), which shows what happens within the plant as water activity and moisture content increase.

“Bacteria and yeast and fungus stops as the water activity gets lower, but as you continue, the enzymatic activity stops. So for a lack of better words: This plant is dying,” she said, before posing the hypothetical question, “Are these the processes we need to look at and understand where we can then really optimize what’s happening in post-harvest?”

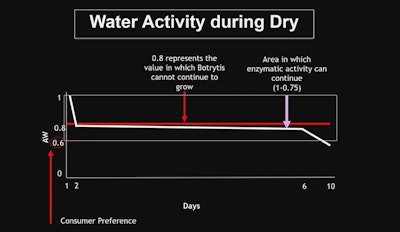

Justice then created the next graph, which provided a guideline for her growers to allow these unknown enzymatic processes to continue to a water activity that consumers desire for smoking—which is around .6 to .65—while reducing risks of botrytis and also preserving terpenes (which can be volatized if drying is done too quickly).

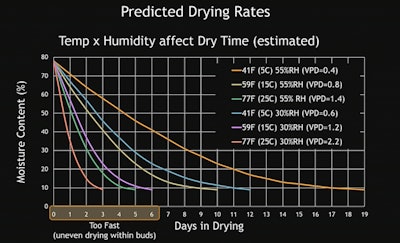

"If I’m in a drying room—and we’re doing the 60/60, which everybody knows (60% humidity, 60 degrees Fahrenheit) … what’s really driving that force of fast and slow is your VPD (vapor pressure deficit), so the combination of temperature and humidity, which will drive the water vapor one way or the other,” she said. “So here’s where some really cool research from [Cannabis Research Coalition] comes in.”

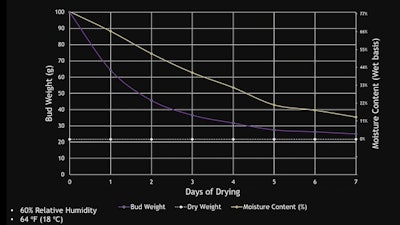

Part 1 looks at drying—examining a CBD-rich varietal called Peach Haze. (In South Carolina, only hemp is legalized, and this research covers smokeable varieties.) The Peach Haze buds were bucked, trimmed, and dried for seven days and placed into sealed jars. This study centers around what’s happening with the gases at different water activities.

At these conditions, the research team was able to get moisture content down to 12%, she said. (Justice flips between moisture content and water activity here because of the measurement tools available.)

“But what about in the dry room? Does it make sense to be able to stay within a certain VPD parameter while drying?” Justice said. “If you’re at 60/60 and that gives you a metric of .59, can you stay within that .59 range and go lower humidity, lower temperature? We’re looking into that and I think it’s very possible, but the problem is you’re getting at very low temperatures and 60 sometimes is hard enough to achieve.”

The above chart examines temperature and humidity versus time. “Drying within six days, as far as microbial growth, is great—but at the same time you’re going to have very inconsistently dried buds,” Justice said. “The outsides are going to be drier than the insides, and you’re probably going to lose a lot of the terpenes because it’s hotter.” On the other hand, Justice said drying too slow runs the risk of mold. The sweet spot is about seven to 10 days, which proves out the legacy methods, she said.

Homogenization. And what is ethylene doing here?

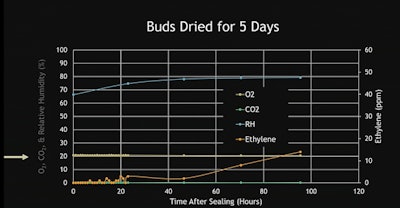

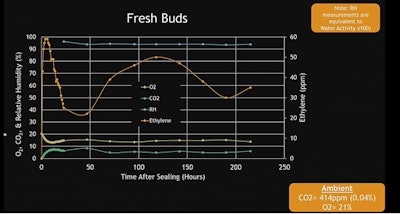

“This is where it gets really interesting,” Justice said. The left axis of the below chart shows O2, CO2, and humidity while the right axis shows ethylene. (The chart also shows time after sealing.)

The blue line at the top shows humidity. Relative humidity in this case is being measured in the jar’s head space (the space between the flower and the top of the container) of the container. At first, the bud is quite humid—but as days go on, relative humidity starts lower, then rises. “Are the buds getting wetter in a sealed jar?” Justice asked. “No, they’re not. They’re just homogenizing.” The humidity in the middle homogenizes to the outside and when everything begins to normalize, the humidity in the head space increases, she said. “So I think we can say drying/curing is a homogenization step.”

The orange line below represents ethylene, a ripening gas. “If you think about cut flowers,” Justice said, “we put actual sachets inside when shipping cut flowers to stop ripening … [to] take away that ethylene.

“So is ethylene good or bad for cannabis? We don’t know. But we can say there’s a lot of it in there.”

Justice said ambient CO2 for an empty jar is about 414 ppm (about .4%) – so low on the chart that it wouldn’t be measured, adding that, “whereas oxygen is about 21%. So in this picture you see oxygen is being removed and CO2 is being added, so to me that tells me there’s your respiration. The plant is still alive, and it’s beginning to break down sugars and all those other things. So if part of curing is the transition, the breakdown of carbohydrates, maybe drying is also curing. I guess we have to decide what the definition of that is.”

As the bud gets drier, down to ambient CO2, ethylene too goes down, but it’s still present at fairly high quantities.

“How do we take that information to help optimize or speed things up, make it better?” she said.

Watch the full presentation—including findings on drying methods to preserve terpenes.

Cannabis Business Times has released the full presentation of Dr. Justice’s talk from Cannabis Conference 2022, which can be accessed here. You can catch all the details from the Cannabis Research Coalition’s humidity and ethylene findings, plus how terpenes are impacted using different drying techniques (including freeze-drying and oven-drying).

Cannabis Conference 2023 will be held August 15-17, 2023. Stay up to date on all speakers, sessions, exhibitors, special events and more at www.CannabisConference.com.