The shift in cannabis lighting over the past few years is indisputable: LEDs now dominate cannabis cultivation hands down. Whether growers are incorporating LEDs in initial buildouts or making their move with retrofits, the body of grower support for LED use continues to expand.

If you are considering a retrofit, gaining knowledge in advance is critical to positioning your grow for retrofit success. Cannabis Business Times spoke with two cultivators, both with in-process retrofits, about their experiences and lessons learned to help shorten your learning curve.

Doing Your LED Homework

Darsey Tanner, director of operations at cannabis cultivator and processor Grow Ohio, recommends researching lighting companies and products thoroughly to find the absolute best fit for each part of your operation—and don’t rush the process.

Launched in 2018, Grow Ohio has 24 flower rooms initially outfitted with HPS (high-pressure sodium) bulbs. While Tanner says they’ve experienced good quality and yields with HPS, the potential LED benefits relating to improved environmental conditions, plant health and energy costs spurred their decision to explore LEDs.

For the past year, one of Grow Ohio’s flower rooms has been devoted to lighting trials with multiple manufacturers. “Quality is our main priority,” Tanner says. “So we really took time to pick out the right LEDs that we thought were the best fit for our room layouts to continue our success.”

Nathan Sanabria, cultivation manager at Oregon-based Shango Cannabis, says the LED homework leading up to their retrofit was also intense. Launched in 2014, the seed-to-sale operation started out with metal halides, HPS and T5 bulbs. Shango Cannabis trialed more than 20 different LEDs before settling on the manufacturer and products that best fit the unique needs of their grow rooms and goals.Photo courtesy Shango

Shango Cannabis trialed more than 20 different LEDs before settling on the manufacturer and products that best fit the unique needs of their grow rooms and goals.Photo courtesy Shango

“We just saw the future being LED,” he says. “We knew it was coming, and we knew that when it came, you were going to have to get on that train, or you were going to be left behind.” So, over the past six years, Shango trialed more than 20 different LEDs before settling on the manufacturer and the product they felt was most effective for their needs.

“We wanted to make sure that whatever path we took was going to be the right one for us,” Sanabria says. “We realized quickly that not all LEDs are made the same. Really quickly. A watt’s a watt, but the array of diodes that people can use and how they specify that array on their fixtures is what makes the difference.”

Both Tanner and Sanabria say that keying in on the unique aspects of your grow is a critical part of the due diligence process in researching LEDs. They advise cultivators to take time to trial multiple LEDs, collect extensive data, and pick what’s best for your quality and your grow. The HPS-to-LED conversion enabled Shango to increase PPFD from 800 to rougly 1000 to 1300.Photo courtesy Shango

The HPS-to-LED conversion enabled Shango to increase PPFD from 800 to rougly 1000 to 1300.Photo courtesy Shango

Defining and Refining LED Retrofit Goals

As Shango envisioned an LED-driven future, Sanabria explains they had broad goals and benefits in mind. “Light intensity was definitely one of them,” he says.

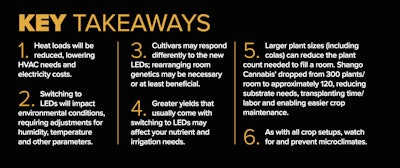

With a watt-to-watt LED replacement of 20 HPS bulbs in one room, he was able to increase from 800 PPFD (photosynthetic photon flux density) to approximately 1000 to 1300 PPFD. However, he’s quick to add that cultivars reacted differently, which necessitated some reorganization of room genetics.

Safety was also a big concern for Sanabria. “HPS and metal halide—any bulb is always prone to fire,” he says, noting that insurance, safety and overall environmental hazards support the switch to LEDs. Profitability was also a driver. With LEDs, Shango can grow faster and turn plants faster, without sacrificing quality. Out of eight flower rooms, only two are still in HPS. Those are expected to transition soon.

For Grow Ohio, retrofit aims included improving canopy leaf temperatures, reducing heat load, and lowering electrical costs. Tanner notes important considerations were quality and construction. For Grow Ohio, that included fixtures that fit well with the winch system used to lower and raise lights in the grow.

The results from the LED trials have been consistent with Tanner’s expectations: “The cost of electric with managing environmentals is a lot better with LEDs. Without them putting off as much heat as HPS bulbs, you don’t have HVAC units running as hard and breaking down. Utility costs are also a lot lower.”

At Grow Ohio, the plan is to gradually replace HPS with LEDs in flower starting early next year. Clone rooms and veg rooms are already retrofitted to LEDs, using different lighting vendors for each growing stage. Clones have shown improved rooting success, and newly double-tiered veg rooms increased plant counts and freed up additional flowering square footage with this shift in lighting.

Tanner shares that several factors were behind their final LED manufacturer selection in flower: “The main reason is [to achieve] consistent PPFD and canopy coverage. We prefer going after deep reds. That’s something that we’ve seen success with. And again, just well-constructed LEDs that fit into our winch system.”

An unexpected benefit was reduced photobleaching, which would occur in some flowering rooms under Grow Ohio’s HPS bulbs.

Making the LED Transition—and Dialing It In

Tanner explains that growers should expect the unexpected and be prepared to make adjustments with the switch to LED. LEDs reduce the heat load in the grow rooms, allowing for better environmental control and quality, but those changes in conditions trigger different nutrient and irrigation needs. Making adjustments and dialing in your environmental conditions is essential to quality.

For Shango, Sanabria shares that the switch to LEDs allowed them to run the rooms at higher temperature and humidity levels. Because heat loads from the lights (and directly on the plants) are reduced, temperature and humidity settings for the entire room can be run higher, which is beneficial to the plants, if managed properly.

“One thing I noticed was we already had so many [plants] that were big yielders, so you’d have these big, giant colas,” he says. “But once we started running it with the LEDs and crop steering and getting yield increases, those colas became even bigger.”

With high temperatures, high humidity and big colas, they discovered there’s a very fine line to walk to avoid bud rot.

Plant nutrients are also a crucial area for adjustments when making the switch to LEDs. After originally running Shango’s normal feeding formula, Sanabria says yields were good, but the team felt that denser buds, more colors, more taste and more flavor were within reach.

“We started tweaking it, and slowly got to where we were feeding 25 to 35% more, depending on the plant. And we were feeding 25% stronger food in the reservoir,” he says. (Larger plants required more nutrients.) Overall, Shango’s yield has increased 15% to 20% with LEDs, with significant gains in A bud. They’ve seen other gains as well.

Sanabria used to put about 300 plants in a room. Now he loads roughly 120 to get the same results. “Same strains, same veg time, same feeding,” he says. “The only difference is we’re just optimizing everything, so when they go into flower, they’re covering such a bigger square footage, and that’s less coco, less transplanting, less hands-on time. And then once it comes to thinning, your guys can just mow right through it.”

At Grow Ohio, Tanner says they’ve seen improvements in plant quality, with comparable or superior yields. Again, the absence of photobleaching under the new LEDS has been a significant boost in bud quality.

Maximizing Your LED Benefits

Whatever your route to an LED retrofit, Tanner and Sanabria emphasize being true to your grow, taking time with your trials, and getting it right the first time. Both growers emphasize the value of collaboration and support from LED providers. Tanner says, “The teamwork between us and the companies that we’ve worked with has led to our success, and we’re very appreciative of it.” For the past year, one of Grow Ohio’s flower rooms has been dedicated to LED lighting trials.Photo courtesy Grow Ohio

For the past year, one of Grow Ohio’s flower rooms has been dedicated to LED lighting trials.Photo courtesy Grow Ohio

Tanner stresses that understanding the spectrum you want—and finding a manufacturer that provides it—is essential to maximize the benefits of a retrofit. “Our preference for deep reds doesn’t mean that the grow next to us also likes deep reds. So, there’s a wide variety of LEDs out there that deliver different spectrums or lights that you can change the spectrum, if that’s something you wish to do.”

Price points, while important, shouldn’t drive final decisions. “Depending on the choice of the construct you go with, you’re going to get different PPFDs and canopy coverages, which play significant roles in the success and the quality your garden,” Tanner says. “These variables highlight the importance of prioritizing quality and data over price when making final decisions.”

Sanabria says maximized LED benefits depend on adequate air movement above and below the canopy. He stresses that, with higher temperatures and humidity in the room, it’s a delicate ecosystem, so growers should make sure there are no microclimates created. “One little microclimate makes such a bigger difference when you’re talking about being in that extra level of temperature and humidity,” he says.

The last piece of advice Sanabria has for growers: Take advantage of LED rebates! He talks to many growers who still don’t know about rebates or don’t go after them. “That is one thing that so many people overlooked,” he says. “… You could get half a light paid for, one light, two lights, anything is worth something, right?”

Sanabria predicts that the windows for rebates and incentives will slowly close as more people transition, and growers not using LEDs will be left behind. He adds, “It might be 20 years down the road, but eventually every grow is going to end up having to be grown with LEDs, for the effectiveness, the energy and the safety reasons.”

Jolene Hansen is an award-winning freelance writer and editor specializing in the commercial horticulture, cannabis and CEA industries. Reach her at [email protected].

Read more from the "2024 State of the Cannabis Lighting Market" report:

Executive Letter: Driving Industry Innovation

Multitier Growing With LEDs: ‘A No-Brainer’Two cannabis cultivators share crucial considerations and significant benefits they’ve seen in pairing vertical growing with LEDs.