The gap between veteran cannabis cultivators and big ag is continuing to shrink as traditional horticulturalists partner with cannabis-exclusive companies to exchange expertise. Allison Justice, Ph.D., is part of that cause, bringing her controlled-environment ornamental and produce growing skill sets to transform the production methods of OutCo, an indoor cannabis cultivation facility based in San Diego, Calif.

When she arrived at OutCo, Justice noticed many practices that needed improvement for better results, as well as lower input costs. One of those was switching from pre-mixed fertilizers to a more customized and less-expensive nutrient program. Another was switching to a completely biological integrated pest management program for cleaner cannabis. Now, she’s also studying light efficiency by analyzing how LED fixtures’ intensity and custom spectra can enhance plant quality.

By conducting in-house trials of two 800-square-feet flower rooms at OutCo, Justice is testing LEDs to learn how light intensity and spectrum impact the success of OutCo’s cultivation and business operations.

Measuring Micromoles

The first study analyzed light intensity in an eight-week trial during the flowering stage of Hazy OG strains. About a third of the room was outfitted with three different LED fixtures with varying levels of intensity, as well HPS fixtures currently integrated throughout the facility to serve as a control.

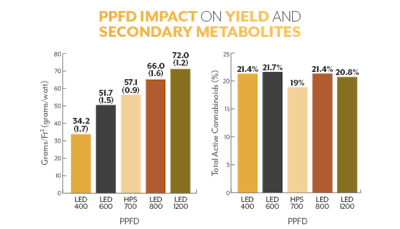

“We were looking at 1,200 micromoles all the way down to 400 micromoles, and what we found was that with the higher intensities, you get higher yield,” Justice says. Because the LEDs give off a lower heat load, she was able to drop those fixtures down to 6 to 10 inches above the plant—which also increased PPFD by 30 percent to 60 percent and increased light-use efficiency by reducing wasted light that typically gets absorbed by walls and aisles.

Another added bonus is that they were using less electricity overall during the trial.

For example, “When we use the [LED fixture]—we were seeing a 13.5-percent increase in yield, but then you also get a 44-percent power savings in your light input. For us, that’s huge,” she says. “This doesn’t even take into account the savings you would get from not having to cool the room quite as much.”

What was most noteworthy, however, is that there was no photo-oxidation or burning of the plants with the ramp-up in PPFD of the LED fixtures. Justice says that there is certainly a possibility of diminishing returns when intensity is ramped up too high—and that threshold was not met in this study. She says she was “quite surprised” with those findings.

Light Recipes

Researchers and manufacturers are still looking to discover the right light spectrum for growing cannabis—although they’re getting closer. The second trial, also an eight-week study of Hazy OG, focused on four different spectra of two different LED fixtures, two of which were standard manufacturer offerings, and two of which were custom-built for the study. Justice and her team analyzed ratios of red, green and blue light—as well as wavelengths outside of the photosynthetic region.

OutCo is also focused on analyzing overall light efficiency (how much energy the lights are using, and the energy plants are utilizing to grow to their maximum potential) based on those spectra.

While results have not been determined yet (once harvested, flower of the nine plants that were measured will be sent to a lab for further analysis), Justice is expecting significant findings. “If I had to guess, I think yield will be pretty similar throughout treatments, but I’m really expecting the secondary metabolites [cannabinoids and terpenes] to show some differences between treatments,” she says.

Research and development is by far the best way to understand light quality and its maximum potential, as well as sustainability, Justice says.

“Nothing speaks louder than data from a properly designed and repeated experimental trial,” she adds. “When my CEO was able to look at our harvest data comparisons of … LED lights versus HPS, our decision to upgrade our rooms was immediate. By conducting in-house trials, we are able to see very quickly how a new technology compares to what our facility can already produce. This has allowed us to improve production and ultimately increase our bottom line.”