Nutrient intake is critical to a cultivator’s crop, and automating this process through an injection system can help ensure you’re administering nutrients to your cannabis plants properly. Here, CropKing President Paul Brentlinger explains how injectors work, and how they can be implemented into your grow operation.

1. What are the benefits of mixing your nutrients into a main reservoir tank?

The use of a main reservoir tank has many benefits. It allows the nutrients and pH adjusters to stabilize prior to being delivered to the crop; it provides an easy location for monitoring and sampling the diluted nutrient mix; and it allows for the manual addition of further supplements on an as-needed basis.

2. What are bellows pumps and how do they work within an injection system?

Bellows pumps are positive displacement pumps that are extremely stable and accurate in delivery. They serve as a means of delivering controlled and exact doses of concentrated nutrient and pH adjuster stocks into the mixing reservoir. Each bellows pump can be fine-tuned manually with a set screw to adjust the proportions. On a typical injection system, these stocks are delivered by a three-headed pump featuring three bellows operating off of a mutual axel. This ensures that the separate stock tanks are delivered together at a user-determined ratio.

3. Can I still use my favorite nutrient line?

Yes, typical nutrient injectors are designed to deliver nutrients split into two stock tanks (A & B) with a third injector for pH control. With that in mind, the addition of extra bellows pumps will allow you to feed as many stock solutions as you like. Up to three bellows can be operated jointly from a single motor. Additional units can be added as needed.

4. What sort of maintenance is typically required, and what kind of support is available in the case of a malfunction?

Typical maintenance for the injector system involves monitoring and cleaning screen filters as needed and annually removing the bellows to clean and check for wear and tear. The motors are entirely sealed and require no maintenance on the user end. With these simple maintenance steps our injector has proven reliable for over 20 years. In fact, many of the first units ever sold are still in operation to this day. In the event that something should go wrong, CropKing stocks all of the necessary components needed for repairs and staffs the expertise needed to walk you through the installation.

5. What is required to install a nutrient injection system?

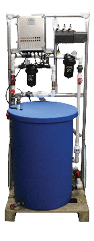

Prebuilt and tested prior to shipping. The CropKing nutrient injection system comes entirely prebuilt and assembled. Each is tested prior to shipping to ensure quality. All that is required on the user end is the attaching of the water supply, the feed output and the stock tanks. We take all the guesswork out of the install.