A “guild” is defined as a group of people with similar interests or pursuits, especially an association of merchants or craftsmen, according to Merriam-Webster. The name couldn’t be more fitting for California’s vertically integrated brand, Guild Enterprises, which is a collective of breeders, growers, extract experts and more, who once operated on their own, but opted to join forces through licensing or collaboration to produce high-quality cannabis products. The Guild brand family includes the entities Guild Genetics, Guild Nursery, Guild Extracts and “The Guild,” the company’s flagship dispensary and vertical grow location in San Jose, Calif.

Founded with the idea that it’s better to band together than navigate the ever-changing cannabis market solo, the strategic partnerships allow the business access to years of industry experience in outdoor and indoor cultivation, as well as advanced extraction technology and a boutique retail presence, which is set to unveil a second grand opening this summer.

Here, Director of Brand Management Claudio Miranda and Director of Cultivation Brook Eagle speak with Cannabis Business Times about how their access to all ends of the supply chain give The Guild a leg up in the industry, how their different cultivation arms expand their horticulture knowledge and brand consistency, their upcoming genetics project, and more.

Cassie Neiden: First of all, how do each of these different Guild brands work together to make a cohesive company?

Claudio Miranda: As a brand-management company, we license the brand and any intellectual property [to our cultivation, extraction and retail partners], [and] depending on what facet of the business they’re drawing on, they would be licensing the brand, actual property and any other consulting services we can provide as an organization.

An example of that would be at The Guild San Jose, [which utilizes] our brand and uses our best practices playbook for the retail, merchandising and marketing strategy. We also then are consulting on the cultivation side; … Brook Eagle, … the director of cultivation [for Guild Enterprises], essentially has been consulting with the store on how to set up their vertical grow.

So Guild Genetics, that brand is strictly correlated with the division of the company that would be developing proprietary cannabis strains. So in that case, it’s a purely R&D-type entity that is engaged in the practice of breeding and collaborations with other breeders in the industry where we’d be creating proprietary strains that would be licensed under the brand.

The Guild Genetics side of our business is a little more in the formative stages. We’ve … developed some proprietary strains, but we’re in the early stages right now, which is why our growers don’t use our strains exclusively.

The second division of our company is Guild Nursery, [which] is focused on nursery production. So the nursery gets the rights to license the Guild Genetics strains by propagating clones and teens, or pre-veg plants that the nursery will wholesale out to other growers.

… We [also] have Guild Cannabis, which [is comprised of] the farms our partners use to grow Guild Genetics, as well as other genetics to sell … under Guild Cannabis as branded flowers.

And further downstream is Guild Extracts, where some of the production from the Guild Cannabis flowering farms can go directly into extract production, where it would then turn into a range of concentrates, and those are all sold and distributed under the Guild Extracts brand.

The final point in that vertical stack is then all these products, whether the branded extracts from Guild Extracts or the branded flower as Guild Cannabis, or the branded clones under Guild Nursery, they can all be sold at retail at The Guild San Jose as one of the stores, but also that product is distributed state-wide … in over 200 dispensaries.

Neiden: How do you ensure that those you license with adhere to your brand’s guidelines as far as social responsibility and product quality?

Miranda: Built into the licensing agreements are standard operating procedures (SOPs), and guidelines and requirements, and anyone who licenses our brand, along with it, is licensing our SOPs and as part of the contract’s requirements … they have to follow those guidelines. So if one of our affiliated companies, let’s say on the extraction side, would start making extracts and are doing it in a way that turns out to be pesticide-laden or [contains] residual solvents, they would essentially … be in breach of that contract.

We are pretty hands-on in terms of the oversight and making sure that everything that comes from the various affiliated companies is abiding by our standards. And one way that we validate that is everything is diligently tested with the various analytic facilities and labs that we find here in California, and not only that, but at Guild Extracts we have in-house analytics as well.

Neiden: Is there a vetting process for your licensees? How are those relationships established?

Miranda: It’s definitely a very strict process. In almost every case, the affiliated companies that we’re working with are partners here. They’re all people we’ve known in the industry for quite some time, and if they’re not, they’re people who come through our general network. And, again, the name of The Guild is operative where we develop this guild, this association where the people that we affiliate with … tend to be people who are very well-respected and have a strong reputation in the industry. … In other words, we don’t just solicit this as a service in the open marketplace.

Neiden: So what, in your opinion, sets the Guild products apart from others in the California market?

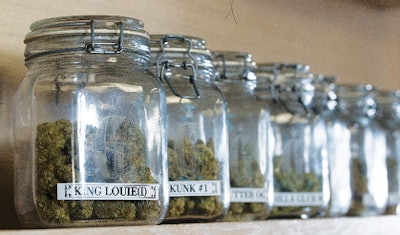

Miranda: That can best be answered on the operating company level or the vertical level. Let’s look at retail alone, for example. … Everything we do is done toward curating the best of the best, having the highest-quality products, the most rigorous standards. So think of us in terms of a specialty retail rather than a mass-market retailer. You would go to Walmart to find everything under the sun …, where you might go to a specialty retailer like a Dean & Deluca or some other very special retailer to be able to get a much more limited selection of product. … [And] because of the limited selection, you’re also getting a lot more depth of expertise and service from the people who attend to you at the dispensary.

And I think the same holds true when it comes to extraction and cultivation. It’s really trying to identify the very, very best strain and flower producers, including Guild, and trying to use the very best methods and techniques, and always pushing that standard as high as possible.

Neiden: The Guild San Jose is the first retail dispensary under the Guild branding, and it also includes a vertical grow system. Can you share more about those projects?

Brook Eagle: I started looking at vertical racking about two and a half years ago, and the reason being that in San Jose, we have a limited power supply. … And we had a limited amount of square footage that we could use for our canopies. So I initially started thinking of going vertical, because we do have very high ceilings there, to maximize our production. I started working with … Fluence LEDs, and I’ve been having amazing results. I’m actually onto my second design—our second room—which you’ll see coming online starting June 1. I’ve been able to take the first design [over] the past year and half and maximize that and change it a little bit, which is exciting.

We grow 100-percent organic. … We use all-organic IPMs, and pest and fungus treatments, and so what drew me to the Fluence lights was the fact that it’s more like sunlight. And you know, in The Guild, all of us really believe that sunlight-grown cannabis is the best cannabis–something about the way the terpenes come out. I feel the plant really grows in its true environment.

Neiden: How is the vertical grow set up? And have you discovered any big challenges to growing vertically?

Eagle: I feel that I’ve been a little ahead of the curve where I think vertical farming is going to be a pretty well-used thing in the industry. Especially in other parts of the country where people are limited on square feet. You can pay less in rent and grow more canopy.

We have two 50-foot racks, and on those racks, … we have two levels of flowering plants. The room is built for a third; we just don’t have the power to go up there. But the plan is [that] we’ll have three levels. And … we use kind of a big, rolling-ladder technique. We don’t have any electric equipment. … We basically do smaller plants, higher count on the plant numbers and just control our canopy on both floors. We have automatic drip irrigation, a CO2-enriched environment, nothing too super fancy in there currently.

The biggest challenge has really been tuning the environment to these new lights. They’re completely different than a normal, double-end HID light, so that was the biggest curve, to really figure out how to control this new environment, with this humidity and its needs, and keeping a perfect world. The lights make the plants actually grow a little bit faster, and so you have to feed a little bit different; you have to respond to them a little bit different.

And the other curve/challenge was basically learning how to, obviously, work up off the floor … and how to not make that a hindrance or something that’s lowering efficiency, but something that’s maximizing efficiency. So there were [practices] we had to develop—pruning leaves or nettings that you do normally on the floor, just as quick and efficient on a second and third level.

Neiden: Going back to the topic of SOPs, how do those really translate through all your different growing operations? What are you able to share across sites?

Eagle: We cultivate different if we’re growing for extracts or not, which kind of changes things.

What we do share is generally the same IPM treatment, which is the pest management. We use basically the same sprays. We do vary nutrient programs depending on what we’re trying to go for. Indoor is always a standard program, but in our greenhouses, we do have to use a different program. …

It’s also just how we work with the employees, what days of the week we trim up the legs and do those things, [which can] vary from greenhouse to indoor. And [in the] greenhouse, you get a lot more vegetative growth, so you’re doing a little bit more hands-on plant work. Also our scales [of production] at the greenhouse are quite a bit bigger, so there’s different SOPs that we have to [use] because of scale.

But generally, [for] most of our grows, we’ve tried to hone in a program where if someone was working in our indoor facility, they would be able to come over pretty easily to our greenhouse facility and know what’s going on.

Neiden: How does cultivation in outdoor, indoor and greenhouse applications help you with strain selection, and choosing the best site for the particular genetics?

Eagle: That’s a good point. It allows us to really look at the numbers. We do strive in our greenhouse to produce what I would consider indoor-quality cannabis. So something that can hopefully fetch that same price. It’s organic, looks as nice, tests as nice. We are potentially going to be supplementing CO2 in our greenhouses to create that higher indoor look and quality. At the same point, in that same environment, our costs are so much lower that we’re able to sell that product for a lot cheaper than someone who is growing it indoors.

That being said, there are a lot of strains, like OG [or] long-lasting sativa, (strains that take 10-plus weeks to flower), that are a little more susceptible to outdoor environment, or even a controlled environment greenhouse, where growing them indoor is a little bit easier. ... We do get the benefit of those, and [a selection of grow operations] also allows us to experiment and be able to use [selected strains] for extractions [and help us determine] how we can get the biggest yield, the best terpene flavors, which is one of the things The Guild [prides itself on], quality over quantity.

We take a lot of pride in growing cannabis that has a lot of flavor, a lot of nodes, a lot of resin. We’re not just trying to pump out the biggest buds or the quickest buds. We want our patients to notice us because of the quality, and come back to us for that.

Neiden: Are you looking to add more automation to your facilities? And how are you looking to big ag to enhance your product?

Eagle: Automation is a big thing: What kind of tools you can use to not necessarily replace employees, but to make the work a lot easier [and] faster for a lot of these big things you have to do daily. And … not only do we have to worry about the plants, but I also have to worry about our costs, and how much is it costing me per gram to grow something, or how do I lower those costs without affecting the quality and still maintaining organic. …

[I’m also learning about] the tools in agriculture right now that can help maximize [efficiencies], and then also seeing ways … for let’s say … how [ornamental growers] prevent powdery mildew in large greenhouses for roses … and studying that, and then seeing how we can adapt that to our own greenhouses. … And there are little tweaks and turns that we’re going to be trying out and adapting that people have been doing for years, just like any other flower agricultural business.

Ninety percent of cannabis growers come from the hills and do not come from big ag. So I think there is this kind of bridge where people in big ag have never grown a cannabis plant. There’s a lot to learn there because every plant grows different, and they don’t understand what you can do to make the quality better. … But they do know these ways of operating large scale. And so that’s what I’ve really been … trying to educate myself on, and working with those people that know that stuff, and helping them understand the cannabis plant better.

Neiden: With mainly cultivation experience, why decide to open a dispensary?

Eagle: San Jose—they’re a little progressive on their regulations, and they mandated that everything had to be inside the same building: your cultivation, your dispensary ... even going as far as making edibles or anything like that all had to be done in-house, so we kind of were forced into the situation that we had to, but ideally that’s what we’d want anyways.

What it allows me to do is grow strains that our patients at that particular location want, so I can actually cater to what people are buying. I can put it right into our own grow. … It also allows me to bring the patients really fresh, quality herb, where they can know exactly … where it’s coming from. It never leaves that building. And it’s protected, it’s stored properly, it’s trimmed properly, all the way from the grow to the jar.