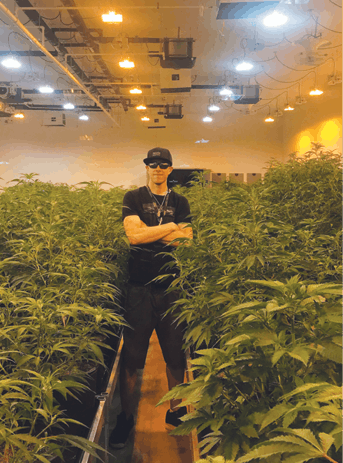

Smokey Point Productions Founder Brian Lade’s years of experience in growing cannabis has taught him both the habits and challenges of producing this somewhat-finicky plant. He initially became involved in the industry as a clone vendor, selling clones to the medical community and then to local farmers and dispensaries.

With the legislation shifting, Lade saw an opportunity to move into full-scale commercial production. The result was Smokey Point Productions, a commercial facility specifically designed to respond to the unique needs of the cannabis plant. Smokey Point Productions was founded in November 2013. The facility is home to a 125,000-square-foot processing and production building in Arlington, Wash.

Opening his own production facility enabled Lade to apply his knowledge to create a space that replicated the environment in which this plant thrived. Over time, he found that one of the biggest challenges was mitigating air-borne pathogens and disease. In fact, Lade found that despite having filters in place, there was always some degree of pathogens in the air.

This finding led to Lade’s desire to create a fully sealed environment to mitigate the risk of outdoor air pathogens. The key is to replicate an outdoor environment, including temperature and humidity, to ensure that the plant flourishes, he says. Chillers help Lade in maintaining the proper climate, without the risk of air exchange. “There are a lot of different pathogens that can come from outdoor air,” Lade says. “I’ve learned through experience that several filters aren’t sufficient in keeping out pathogens, so I grow my plants in sealed rooms with no air exchange.”

The structure includes nine 4,000-square-foot flowering rooms, a large space for the vegetative stage, a state-of-the-art extraction lab and a full processing facility.

When asked about the ideal climate for cannabis, Lade shared that it truly is a personal preference. “I like approximately 80 degrees, and 60 [percent] humidity, and a light breeze as well, to move the air around,” says Lade. “It’s like a really nice day at the beach.” However, maintaining that climate indoors can be extremely difficult, if not impossible, without the proper HVAC units.

To create this environment, Lade opted for a water-cooled HVAC system, which has allowed him to easily control both the temperature and humidity. The chiller units are located outside the building, chilling the liquid down to 44 degrees. The system then pumps water, not air, throughout the piping in the building, eliminating the need for ducting. This also helps ensure that the environment remains fully sealed and protected from external containments. If the temperature of the internal environment needs to be raised, Lade simply raises the temperature of the water.

“There is not much to break or to change, and the maintenance is fairly minimal,” says Lade. Each room is equipped with air handlers that frequently turn on and off throughout the day to reduce odors and ensure a continual air flow. “The air is coming from the floor-up, which provides a nice, gentle breeze throughout the environment,” he adds. Because it is a fully sealed environment, carbon dioxide is released at the ceiling level at varying levels, depending on the specific needs of the plants: higher for the blooming room, lower when they are in the vegetative state.

Determining the right environment to grow cannabis should be an ongoing process. Growers need to invest the time to understand both the needs of their plants and the environment in which the plants will best respond. When it comes to growing cannabis, it is partially about achieving the right vapor pressure deficit (VPD), and finding the combination of heat and humidity that works best for the plants, says Lade.

“There isn’t one perfect environment. If it’s hot without adding humidity, the plants won’t like it,” he says. “If you go cooler, you can place the plants at risk for botrytis. There is always some fine-tuning involved.”

Investing in a climate control system helps ensure that you have a fully controlled environment that will provide both the temperature and humidity levels that the plants will respond best in. “The key is to find the levels that work best for your plants and put the system in place that will allow you to generally be in that range,” Lade says.

Working with a professional company that understands the specific needs of the cannabis industry will help ensure that the right system is in place from the get-go. This includes a system that can adapt to weather and humidity fluctuations and a generator back-up in case of a system failure.

The price for such a system will vary with the size of the operation. Smokey Point’s current system supports a little more than 1,000 lights and cost just over the million-dollar mark. One of the biggest mistakes that growers make is trying to cut costs in HVAC systems early on, then having to add on later, Lade says.

“The real cost in the business is choosing not to invest in the proper HVAC systems,” Lade says.