“Blackout systems are not new to the horticulture industry,” says Dave Bishop, regional sales manager for Conley’s Greenhouse Manufacturing. “When [they] were first used, it wasn’t critical that every bit of light and shadow was blacked out — just the majority of it. Cannabis growers, however, believe that every pinhole of light has to be blocked out. So the advancements in the systems have been in that sense … and from truss to truss, so that it seals completely.”

“The cannabis industry has created a demand for a better blackout,” agrees Mauricio Manotas, president of Ludvig Svensson, which manufactures technical textile solutions. “The light-sensitivity of the crop (and the value) has pushed companies like us to work diligently in that direction.”

Multi-Purpose Solutions

“An automated blackout system typically serves a couple purposes,” says Bishop. “One, to black out the sunlight. … Also, in a lot of counties and even states where cannabis is legal, they don’t want light pollution. [So], when supplemental lighting is needed at night, the blackout systems keep the light from going out. The third function is that in colder-weather conditions the curtains can be pulled shut at night to keep it warmer,” and reducing the energy bill.

Two Layers or Three?

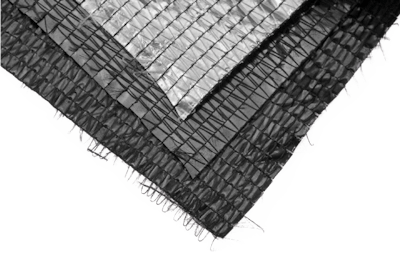

“Black out material went through its own development, away from simple black plastic,” says Peter Stuyt, vice president of Total Energy Group Inc., a greenhouse equipment manufacturer and retailer. “Different combinations of black, laminated and aluminized material are now available, for blackout mostly in two-layer combinations. In cannabis, grower expectations will make us use three layers, and I have worked with systems carrying four layers of material.”

“Right now the industry ‘standard’ is a triple-layer, normally with two layers of black and one layer of aluminum or white,” says Manotas.

However, three layers is more expensive and isn’t necessarily better, says Patricia Dean, CEO of Wadsworth Control Systems, which builds complete blackout systems, from the motor controls to the environmental controls. In fact, she says, “We conducted a study using light sensors … and found that two layers is sufficient versus three layers.”

Three layers also doesn’t allow for as much “breathing,” says Dean. “Some growers [in traditional agriculture] cover the greenhouse with the blackout curtain, and then … when it’s dark, they’ll uncover it to increase ventilation, reduce humidity. But cannabis growers don’t want to do that.”

Growers, especially in warmer climates, like southern Colorado, says Dean, “would benefit from using a dual curtain system — with one shade and two blackout layers. Some growers on the hottest days will cover the greenhouse during the day with the blackout layer to keep out the heat. But with the dual-system, the shade, which is an open-weave so air can flow through the curtain, can be closed during the day and will cool a greenhouse by 10 degrees, depending on the humidity and other factors.”

What’s Important to Look For?

Manotas suggests growers look for companies with a history in the greenhouse industry. “We take into consideration the geographic location, climate, greenhouse type to recommend options. We also have most of our products tested and developed as Fire Rated, which, with the … equipment on these houses (lights, motors, etc.), is an extremely important feature,” and often a must to meet local fire codes.

Local support is also important, he says.

Stuyt says, “Since reputable shade and blackout fabrics carry a pro-rated warranty of five years, the system hardware should last as long without too much hassle.”

Bishop says growers should look for “references [or a guarantee] that the system will black out the light, since you won’t really know until the system is up.” It’s also important, he says, “[that the] system … has a simple, automated control system, so it’s easy to change the control panel from 12 to 15 hours of darkness.”

Editor’s Note: This article is an update to the article, “The Dark Side of Cannabis,” which appeared in the March/April issue of Cannabis Business Times. That article listed commonly used blackout-system materials, but those materials are used by extremely small, typically non-commercial grows. Here, CBT explores materials used in large-scale, modern greenhouses.