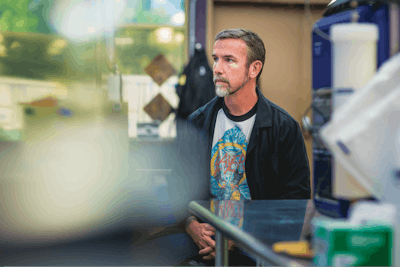

Entrepreneur. Cybersecurity expert. Product developer. Operations expert. Musician. Guitar tech. Cannabis and hemp pioneer. David Bonvillain’s resume is the paragon of hard work.

He brings that work ethic to everything he does, including his ownership of Elite Botanicals, a CBD-hemp cultivation, extraction/processing and product development business with operations in Loveland, Colo., and partner farms in Byers, Greeley and Yoder. He is also the owner of The Bonvillain Group, a consultancy currently advising clients in Missouri, California, Colorado and Connecticut; is a co-owner of Elite California, a licensed THC-focused division with operations in the San Luis Obispo County area of California; and he produces a line of CBD products for pets that he distributes through Mary’s Nutritionals under the Whole Pet brand.

Bonvillain might not yet be a household name in cannabis, but most CBD consumers in Colorado and many across the United States have used at least one of Bonvillain’s products, even if they didn’t know it. That’s because Bonvillain partnered with super-brands like Mary’s Medicinals, Cheeba Chews and IncrEdibles to provide them with all the CBD oil they need in their edible and topical product lines, as well as develop new products targeted to each brand’s consumers.

Between Elite Botanicals, Elite California, the Bonvillain Group and managing relationships with partner organizations, Bonvillain works 12-hour days with no time for breaks—until this year, when he took his first “vacation” in more than 15 years and toured with his all-time favorite band: Slayer.

What was supposed to be a two-week hiatus turned into a two-month escapade as Bonvillain unexpectedly became one of the band member’s official guitar techs. Out of all the jobs he’s held, touring with Slayer is by far the toughest, he says. “The crew starts working at 7:30 in the morning and keeps going until 2 a.m. and then does it again the next day. The day that I would get off, I slept all day because I’m f---ing 45 and shouldn’t be on the road with a rock band.”

Despite his prolonged absence, Elite Botanicals was able to continue business as usual. That’s because instead of building a company that depended on him, Bonvillain built a business that was made to survive without him.

The Right Partners

Following several years of consulting in the regulated cannabis industry under Elite Cannabis Enterprises, Bonvillain launched Elite Botanicals in 2013 after a meeting with Dr. Alan Shackelford, the renowned medical doctor who treated a then 7-year-old epileptic patient named Charlotte Figi with cannabis oil made from a Stanley Brothers strain that eventually took her name: Charlotte’s Web. Since Bonvillain had a reputation as one of the top hobby cultivators in Colorado for his small caregiver grow of about 40 plants, Shackelford turned to him in search of more CBD oil.

Bonvillain admits that before the Shackelford meeting, he had not heard of CBD. (This was before Dr. Sanjay Gupta’s groundbreaking 2013 exposé on Charlotte’s case on CNN, he explains.) However, when he saw the relief the oil brought Figi, he and his team began searching for CBD-dominant genetics to study and cultivate.

“We just kind of went on the warpath for several months and collected seeds and cuts and such from all over the country and the world. Folks were sharing them with us, we bought and tested hundreds of seeds, or we had friends in California where Lawrence Ringo [the founder of SoHum Seeds and a CBD pioneer] had been working with CBD genetics for a while, and so we acquired a bunch of those varieties,” Bonvillain says.

Fast-forward five years, and Elite Botanicals has gone from growing 40 cannabis plants to working with three multi-acre farms in Colorado and California. His Loveland, Colo., location sits on 40 acres—although currently only 1 acre is used for outdoor hemp production. (Partner farms are leveraged for an additional 20 acres of planting, with an expected 2018 production of more than 20,000 pounds.) Plus, a 21,000-square-foot greenhouse is on its way, which will boost Elite Botanicals’ yearly output by 8,000 pounds to 10,000 pounds. Loveland is also home to Elite Botanicals’ extraction and processing lab and manufacturing facilities.

By associating early on with Mary’s, Cheeba Chews and IncrEdibles (the relationships with all three companies started in 2014 or earlier, right as Bonvillain began CBD-hemp production), Elite Botanicals has been able to grow and thrive in today’s crowded market. Being integrated when it comes to cultivation, extraction and processing helps lower production costs, and Elite’s partnerships have also helped cover distribution, branding and sales costs.

Leveraging other brands’ strengths allows Bonvillain to focus on his own. “What I do really well is coming out with these new products and being able to implement them in the lab and train people around how to make them. [Our partners] already have a brand that’s been out there that people know and trust, so together we get it right.”

Molecular Cannabis

Elite Botanicals’ ability to create and perfect new products stems directly from the company’s approach to hemp cultivation, which Bonvillain calls “molecule farming.”

“We’re just trying to get things distilled down to where it’s a pure cannabinoid or a purified full-spectrum oil, and then are frequently isolating terpenes up front and then blending that back together on the back end,” he explains. Instead of concerning themselves with the flower’s aesthetics, the team looks at the whole plant and whether it “has the right amounts of [cannabinoids and terpenes] we are looking for in it,” he says.

Bonvillain obtains cannabinoid profiles with high-CBD ratios not by growing hemp varieties per se, but rather by timing harvests to the crops’ development. For example, Elite Botanicals is growing a type 3 drug variety with a 20:1 CBD-THC ratio or higher (and now many other hemp farmers across the U.S. are doing the same). At full maturity, that plant could have a cannabinoid profile of 20-percent CBD, 1-percent THC and a 3-percent make-up of other cannabinoids—but it would not qualify as hemp. (Hemp is defined as a cannabis plant with a THC concentration of less than 0.3 percent.)

“But if we cropped it at day 40 [as opposed to day 70], it would [qualify as] hemp, and we would already have 10 percent [CBD and little to no THC]—and the company doesn’t have to have all of the incredible costs that are associated with these regulated grows in order to grow CBD,” Bonvillain explains. (According to the state of Colorado, the initial cost of a hemp cultivation license in Colorado is $500 plus $1 per acre [outdoor] or $0.33 per 1,000 square feet [indoor or greenhouse], while a medical cannabis cultivation license can cost more than $25,000, depending on the size of the business.) Harvesting early naturally reduces oil yield and reduces flower production, but Elite is able to make up the difference by volume of biomass produced and by maximizing the extraction capabilities in the lab.

Currently, harvests are hung in a climate- controlled area, though not much environmental adjustment is needed as Colorado’s climate and elevation do a lot of the heavy lifting on dehumidification. Even so, Elite plans to have that process automated by next harvest by using either a belt or louver drying system like those found in traditional agriculture. The amount of biomass these systems can process will allow Elite Botanicals to quickly dry flowers and sugar leaves in bulk, saving time and staff-hours dedicated to hang-drying. Once dried, the biomass is turned into an easily extractable form by passing through a grinder.

Along with the anticipated production increase, Elite is utilizing more alcohol-based extraction techniques since most of the product will end up in distillation. “We could do a fresh-frozen hydrocarbon run … but given what we’re going to take it through on the back end [in distilling the cannabinoids], there’s no real point in that. … Those methodologies are for connoisseur combustible and vape products,” he says. “We might as well just run it into a big alcohol vat and have the alcohol slurry create a solution of very well-extracted cannabinoids.” The alcohol will be recovered using rising/falling film evaporators and will run through wiped-film and short-path distillation units. “And ultimately it just pulls it all out at the end as 85-, 90-percent pure cannabinoid oil.”

Hire to Train

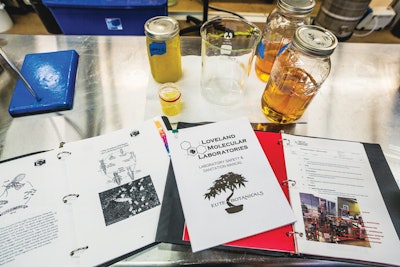

The extensive standard operating procedures (SOPs), which Bonvillain and his team have developed over several years operating Elite Botanicals and serving as consultants at various grows across the country, clearly outline each step of every cultivation, extraction and processing task. The SOP guide is more than 200 pages, according Bonvillain’s count.

In addition to dictating how every task from pest scouting to product recipes should be performed (each SOP ranges between one and four pages per tool, function or piece of equipment), “there’s a good 40 or 50 [pages] on both the lab and the cultivation side that’s really almost like a handbook. [It’s] less of the detailed SOP behind this system or this procedure or this piece of hardware and more, ‘Here [are] our best practices as a company,’” he says.

The reason why Elite developed those extensive SOPs goes beyond compliance: Having job duties outlined with steps on how to do them allows the company to hire passionate workers and teach them the skills they need to do the job, instead of searching for staff with specific expertise.

“I don’t necessarily need to hire the guy that has 10 years of entomology experience to come in and look for these bugs. I need to be able to say, ‘Here are the five types of pests that we’re going to see most commonly, and this is what I want you to look for on those plants,’” he says.

Bonvillain’s approach to assembling his team is simple: Find passionate people willing to work and learn, promote from within and only look for outside talent when necessary.

Actually, Bonvillain tries not to hire people with previous experience in the field. “We generally don’t hire people from the cannabis industry … because a lot of times, it brings either the wrong methodologies to play or brings a level of entitlement that doesn’t work well with the team,” Bonvillain explains. “I haven’t found anything that either I or someone on the team can’t just learn ourselves. And so, generally, we just figure it out, then build the SOP around it and make sure anyone on the team can do it.”

This method of developing and training employees generates higher loyalty, Bonvillain says. For example, Tara Dorr, one of the team members, worked as a waitress before joining Elite Botanicals as a field worker. When she showed interest in working in the lab, Bonvillain trained her using the SOPs he had developed and then collaboratively wrote new SOPs based on new processes being learned or implemented. Today, “she does solvent-based extractions and winterization, fractional distillation, and then really moved on to the product-development side of the house where she now creates new products and controls accurate dosing,” he says.

“It’s important with any sustainable business that you have a team that you can trust and rely on.”

Enjoy Your Vacation

Despite his best-laid SOPs and contentment with the caliber of his team, Bonvillain still was not comfortable leaving the company behind for two weeks.

“It was very difficult just mentally to take those kinds of breaks. But I think for your own sanity, for the sanity of everybody you’re working with,” breaks are needed, Bonvillain says. He admits that when two weeks turned into two months, it made for a difficult catching-up process, and he does not recommend any business owner try to replicate the experience; but it was an opportunity that he couldn’t miss out on, he says. “And what I’ve learned is that it does bring a fresh perspective that you can apply back to your business.”

During his two-month road trip with the band, Bonvillain promoted the various CBD products Elite and its partners make and interacted with consumers at concerts and fellow crew members who were working alongside him.

“I sit and live and breathe this stuff,” he says, “so it was interesting from a cross- promotion perspective as there were several folks that really needed and relied on CBD products in their daily life and understanding their challenges and expectations was enlightening.”

From a work-ethic perspective, he says, “It gave me insight into another industry of people that work their asses off and clock in insane hours away from their homes and families for not a whole sh--load of money. The lack of entitlement and willingness to do whatever it takes to get the job done is impressive and refreshing.”

His vacation also gave his team a chance to prove themselves capable of running the business. He still held weekly calls to make sure that the management team was supported and production deadlines were being met, but having a set of well-defined SOPs and a team that cares about the company and the work they do helped avoid any significant complications.

His team met his standards during his absence, and Bonvillain is already off on his next adventure. As you’re reading this, the 45-year-old is on tour again and can be found either head-banging in the wings of a Slayer concert as he waits to hand off the next guitar, talking about CBD or sleeping off his day’s work in a bus moving to the next venue. Either way, he knows his business will be just fine.