Cannabis Business Times’ May 2018 issue reported that vape cartridge sales in California reached $100 million for the combined months of November and December 2017. The next bestselling concentrate product during that time was wax, with $7.4 million in sales. The stated total of all concentrate revenue in California for that same period was $140.9 million.

Based on those figures, it’s clear that vape cartridges dominate sales. But why? The simple answer: user convenience.

With this data, some companies will successfully focus strictly on cartridge sales, but the cartridge industry is destined to become competitive and saturated. Everyone has, or will soon have, their own branded cartridge without a strategic advantage like a rare cultivar, proprietary device, or efficient and/or superior extraction methodologies and practices. I believe many companies will produce a vape cartridge that is no better nor cheaper than the rest, and these companies will suffer due to little or no brand recognition and will struggle to compete with products that possess strategic advantages (such as the ones mentioned). Therefore, extract companies need to find means to efficiently produce a diversified range of concentrates—and not rely strictly on vape cartridge sales.

Consumers will ultimately demand a wide range of products and offerings. Future consumers will be educated on cannabis’s nuances and characteristics. In turn, many will prefer to purchase superior- tasting, connoisseur-quality products over artificial or formulated flavors or poor-quality concentrates. If the superior offerings are affordable, that is all the better for the consumer.

In the first part of this special extracts series, we reviewed a wide range of concentrates concocted from different extraction processes. This is where production economics come into play. Extractors need to be mindful not only of a product’s strategic market advantages over another, but also the costs associated with extraction equipment as well as the cost of required basic materials (such as solvents) that can accumulate rapidly and increase production overhead.

Each extraction apparatus, whether CO2, ethanol, butane or a hand-press, requires labor of some sort. Some are more user-friendly than others. Typically, the more complex an extraction and refinement method is, the more training the technician will require. Therefore, a highly trained technician (or an employee with a Ph.D.) will require a higher wage than a person performing simple tasks, which ultimately impacts a business’s cost of production.

The concentrate’s final form is most often dictated by the primary extraction method or by the final super refinement. It all depends on what you want the final form to be and how much it costs to produce. CO2 extraction equipment is costly depending on the unit’s capabilities and requires a well-trained operator. Rosin, dry-sieve or water hash require more rudimentary equipment, and employees producing these products do not require extensive equipment training. Comparing the material and labor costs of CO2 extraction to that of rosin presses reveals a stark dichotomy: CO2 extraction equipment can cost hundreds of thousands of dollars, while commercial rosin presses might cost a few thousand. Odds are, the person operating the CO2 equipment makes a higher wage than the rosin-manufacturing technician.

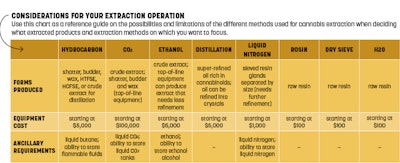

What follows is an abbreviated explanation of the idiosyncrasies and strategic advantages of each method and the associated requirements of each regarding ancillary costs. Again, the ability to produce a business plan around one method depends on the concentrate’s final form, the overall volume of material you intend to process, the combined equipment cost, labor costs, ancillary cost of each, and the associated legal requirements regarding laboratory requirements and licensing considerations.

Hydrocarbon Extraction

- Forms produced: shatter, budder, wax, HTFSE, HCFSE, or crude extract for distillation, or terpenes to be added to distillate.

- Apparatus cost: $5,000 to $100,000 depending on size and capabilities.

- Technician skill/cost: educated in basic chemistry/moderate.

- Ancillary requirements: legally licensed, compliant laboratory; ability to store flammable fluids, liquid butane.

- Compounds targeted: all available cannabinoids, CBDA, THCA and all available terpenes. If required, material can be pre- or post-decarboxylated to produce a decarboxylated version of available cannabinoids at the expense of terpene content.

- Note: If extracting hemp CBD only, technicians may not be required to obtain all the same licenses or permits as they would if extracting THC. (This is also true regarding CO2 extraction and other methods of extraction.)

CO2 Extraction

- Forms produced: typically a crude extract that requires further refinement of one form or another, be it winterization or filtration. That said, equipment manufacturers have begun producing superior equipment that produces a more refined product. Some processors are producing shatter, budder and wax.

- Apparatus cost: between $100,000 and millions of dollars, depending on size, capabilities or automation abilities.

- Technician skill/cost: educated in basic chemistry/moderate.

- Ancillary requirements: legally licensed, compliant laboratory; ability to store liquid CO2 tanks.

- Compounds targeted: all available cannabinoids; resulting extract has very low amounts of monoterpenes.

Ethanol Alcohol

- Forms produced: typically a crude extract that requires further refinement of one form or another, be it winterization or filtration. Similar to modern CO2 extraction equipment, manufacturers are now producing superior equipment that produces a more refined product that requires less labor to super-refine. But most extraction facilities further refine ethanol extracts through distillation after winterization and/or filtration.

- Apparatus cost: between $5,000 and millions depending on size, capabilities or automation abilities.

- Technical skill/cost: educated in basic chemistry/moderate.

- Ancillary requirements: legally licensed, compliant laboratory; ability to store ethanol alcohol.

- Compounds targeted: all available cannabinoids, resulting extract has low amounts of monoterpenes.

Distillation: Thin film, short film, wiped film

- Forms produced: a super-refined oil rich in desired cannabinoids, be it THC, CBD or a multitude of others in composition. The resulting product can be left in oil form, meaning the THC (or other cannabinoids) can be crystallized.

- Apparatus cost: between $5,000 and millions depending on size, capabilities or automation abilities.

- Technician skill/cost: highly educated in chemistry/high.

- Ancillary requirements: legally licensed, compliant laboratory.

- Compounds targeted: all available cannabinoids; resulting extract has low amounts of monoterpenes.

LNZ (liquid Nitrogen)

- Forms produced: sieved resin glands separated by size (crude form of extract that can be further processed or refined into almost any form).

- Apparatus cost: $1,000 to millions depending on size and capabilities. As of now, there is no version of this apparatus for sale. Extraction facilities that utilize this method are currently manufacturing their own equipment to suit their requirements.

- Technical skill/cost: basic understanding of chemistry and gravity/moderate.

- Ancillary requirements: legally licensed, compliant laboratory or ability to extract directly in growth environment (i.e., directly in greenhouse or in the field), lots of liquid nitrogen.

- Compounds targeted: all available cannabinoids and terpenes.

Rosin (heat and pressure press)

- Forms produced: raw resin, typically stable and slightly hard when cool, ranging from a stable mass to viscous fluid depending on starting material and method, temperature, pressure and duration time of pressing.

- Apparatus cost: $100 to $10,000+, depending on size and capacity capabilities.

- Technician skill/cost: basic understanding of chemistry/moderate.

- Ancillary requirements: legally licensed, compliant facility.

- Compounds targeted: all available cannabinoids and terpenes.

Dry Sieve (specific sized resin glands)

- Forms produced: raw resin, preferably of targeted size mature glands.

- Apparatus cost: $100 to $10,000+.

- Technician skill/cost: basic understanding of chemistry/moderate.

- Ancillary requirements: legal, licensed and compliant facility.

- Compounds targeted: all available cannabinoids and terpenes.

- Note: This form of extract can be refined and manufactured into a multitude of extract forms.

H2O Extraction (water extraction) (specific-sized resin glands)

- Forms produced: raw resin, preferably of targeted-size, mature glands.

- Apparatus cost: hundreds to thousands of dollars.

- Technician skill/cost: basic understanding of chemistry/moderate.

- Ancillary requirements: legally licensed, compliant facility.

- Compounds targeted: all available cannabinoids and terpenes.

- Note: This form of extract can be refined and manufactured into a multitude of extract forms. Water-extracted resin glands contain lower amounts of water-soluble terpenes because they are absorbed and lost in the waste water.

Most of these concentrate forms can be refined and manufactured into a multitude of consumer goods and products. The key to efficiency is to determine what final extract form you desire, then decide which method or apparatus suits your requirements, and how that equipment and the resulting ancillary requirements fit within your business plan.

I have seen many interesting things in my years of concentrate consulting. For example, one individual who insisted he could produce a better rosin press went to China, had some sort of press fabricated and shipped it to Oregon where it has sat unused for two years, never to press a speck of cannabis.

Another group called me rand stated that their intent was to take hydrocarbon extract and increase its value via further distillation, which I explained was unlikely unless they were extracting very poor-quality hydrocarbon extracts.

The point from these two misadventures is this: Don’t over-complicate your extraction process. Figure out exactly what concentrate form fits your business plan, then figure out exactly which method suits your needs and stick to it.