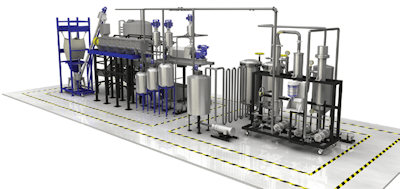

Isolera Extracts is set to finalize its build-out by late February, and CEO Jack Tatum is extremely pleased with the progress thus far. He found a welcoming home for his company in North Carolina’s supportive hemp industry, where the team at Precision Extraction Solutions has been helping him get his extraction business off the ground. Tatum secured a former Burlington manufacturing facility in Oxford, N.C., and upon completing build-out of the 187,000-square-foot space, Isolera is set to take the CBD isolate world by storm.

After working in the cannabis space for the past decade, Isolera is Tatum’s first hemp-centric endeavor. Precision has helped get him up and running—and the timing couldn’t be more fortuitous with the passage of the 2018 Farm Bill and its hemp legalization provisions.

Much of the domestic hemp industry is split off into either fiber or cannabinoid extraction. Isolera’s function deals with the latter.

“Looking at the extraction space, we had made a conscious decision that we wanted to go with the most professional of outfits,” Tatum says. “We made a great decision, the relationship with Precision has been phenomenal from the get-go. They really allowed me the opportunity to focus on the business side of things while leaving the technology to the pros.”

The initial business side of it meant taking a good look at how Precision’s hydrocarbon and ethanol extraction equipment will fit in with broader market supply and demand curves. With Precision’s equipment, Tatum says his company can initially process about 3,000 pounds of hemp biomass every eight hours.

“It’s perfectly designed for what we’re doing, including quick scaling of operations,” he says.

Within six months, he hopes to ramp up to about 10,000 pounds per day. Tatum says the Precision team has gone to great lengths to work their equipment into site development plans at the Isolera facility. From meeting with the local fire department and code officers to offering expert perspectives on SOPs, Precision’s team plans on using Isolera’s experience as a model for other businesses going forward.

“Having dealt in this space for some period of time, I was really impressed with how important and key they were in the initial process,” Tatum says. “And they were all-hands-on-deck from start to finish. They're still hand-in-hand with us right now.”

Tatum’s experience is a testament to the demands of transitioning from cannabis to hemp in a rapidly evolving U.S. marketplace.

“When we saw the size and scope of this, I realized that this was going to be a major undertaking—not only from an economic perspective but also to be done correctly. Precision has in-house engineering, as well as site-development experience, so they really got on board early with us, including meeting with the municipalities … and even local farmers. Precision got everybody comfortable with what we were trying to do and then ultimately designed the facility. The build-out is almost finished, as far as the construction aspect is concerned, and my experience with Precision has been a real pleasure.”

Next up: Precision will be working to train the team at Isolera in conjunction with the regional governmental agency NCWorks and the nearby Research Triangle.

A broader goal is to see how Isolera’s large-scale extraction work will open up possibilities for new cannabinoids and more in-depth research in North Carolina and on the federal level. “We're excited about working hand-in-hand with not only world-class, finished products, but also the development of potentially new products that we haven't seen up to this point in time.”