Decorticators used for hemp fiber processing come in many shapes and sizes, from old-fashioned manually operated hemp breaks and modern hand-cranked tabletop versions to small-, medium- and large-scale mechanized models powered by motors and integrated into fully automated industrial production lines. To avoid supply chain issues and cut out the middleman, growers have the option to purchase their own decorticating equipment. Here are five tips for selecting and using the right decorticator for your operation.

1. Match automation with your operation’s scale.

Before buying a decorticator, consider the scale of your operation and plan a level of automation that will suit it accordingly. Are you planning to process hundreds of large, round bales of hemp or just a few hand-harvested bundles of hemp stalks you can move without machinery? Larger systems have higher upfront costs but will save many hours of manual labor.

As you scale up hemp decorticating operations, power requirements and noise levels will increase. It’s important to remember you will also need additional material-handling equipment. In chronological order of when each handles the hemp, additional types of equipment include:

- bale unwinders;

- conveyors;

- dust collectors;

- post-milling classifiers; and

- storage systems.

2. Ret for the proper amount of time.

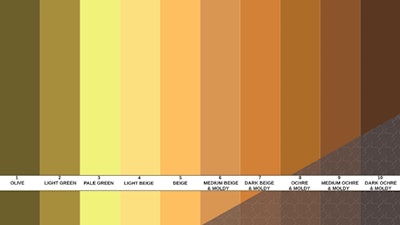

When using a decorticator, consider the degree of retting your hemp has been through. Proper retting breaks down the lignin that bonds the bast fiber to the hurd during growth, which makes mechanical separation of the two much easier and will yield the best-quality fiber. There are a few different types of retting to consider—dew retting in the field is a popular option among hemp growers because it doesn’t require a significant investment—and it is as much an art as it is a science. Over-retting degrades fiber quality and strength and can lead to mold. Under-retted hemp makes decortication more difficult and leads to coarser fiber. Properly ret by observing the color and applying the snap test.

3. Decorticate as close to the farm as possible.

Regardless of scale, all fiber hemp should undergo some degree of processing near the farm to reduce weight and increase value before transport. The goal of decortication is separating the bast fiber from the hurd as much as possible, as both stalk components can be used separately to create a variety of products. (For example, bast fiber can be used to create textiles and rope, while hurd can be used to create animal bedding and composites, to name just a few products.) A good baseline benchmark is 95% clean fiber (with 5% or less hurd remaining) and 95% clean hurd (with 5% or less fiber remaining). The closer you can get to 100% separation, the better. Separation percentage is mostly a result of how the fiber and hurd are screened and classified post-decortication. Decortication only crimps and snaps the stalks, while secondary processing (classification) is necessary to achieve complete separation.

In addition, both fiber and hurd should have a minimal level of dust. Large-scale operations should use dust collection systems, but if you work at a smaller-scale operation, you can work in a breezy or well-ventilated area and make sure you shake off as much dust as possible while you are working.

4. Watch out for issues during decortication.

The orientation in which you feed the stalks into the decorticator can affect its performance. Some machines require the stalks to be oriented parallel to the flow of material to yield good results, while others can accept stalks without any particular orientation and still achieve adequate separation. (The diameter of the stalks should be between three-eighths of an inch and a half-inch to increase consistency in retting and decortication.)

Also, when using a mechanized decorticator, it’s important to be aware of:

- jamming (feeding too much material in at one time);

- wrapping (caused by unguarded rotating parts); and

- dust (which needs to be removed via dust collection or forced air).

5. Have a plan for after decortication.

Think about what you will do with your processed material before you begin decorticating. You should have a plan for your output receptacles—how will you capture the output from your decorticator, and how much storage capacity do you have before you need to transport the material to the next stage of the supply chain? Hemp fiber and hurd are very bulky materials, but super sacks, dumpsters, gondola and gaylord boxes, and cargo containers can help.

Last and most importantly, before you consider setting up decortication, you should ensure you have an economically viable plan for your outputs. Search for connections who are looking for growers and will pay a fair price. Make sure you can meet the target yield with a lower cost of production than what the buyer is willing to pay. If the math doesn’t work, then it isn’t a good deal.

Rachel Berry is the founder and CEO of the Illinois Hemp Growers Association, a women-led benefit corporation and grassroots organization representing over 700 members. For more information, visit www.illinoishga.com. Berry is a first-generation regenerative farmer raising poultry, growing heirloom vegetables, native medicinal plants, and industrial hemp with her family on their 13-acre homestead.