1. Let’s start with the big burning harvesting question. Should you trim cannabis wet or dry?

Whether to trim cannabis wet or dry is largely dictated by the harvest’s purpose. As the landscape evolves and extraction products gain market share, an increasing number of producers are freezing harvests to preserve cannabinoids and terpenes. This requires a trimmer capable of processing wet plants.

For smokable flower, growers typically apply a wet cut to accelerate drying and then perfect the final appearance with a dry trim. Once dry, flowers are incredibly delicate and require gentle buckers and trimmers specially developed for the task.

2. Will automated trimming machines eventually replace hand trimmers?

I think the industry will always have a place for hand trimming, but if the question is, “Do I think machine trimming will become the industry standard?” then I’d say it already has. In today’s regulated market, hand trimming your entire harvest is no longer commercially viable or conducive to industry compliance. Despite being romanticized, hand trimming rarely raises standards enough to justify its cost or inconvenience.

Even micro-cultivators are producing 175-pound harvests, which could take 25 dedicated employees seven days to trim. This is not only inefficient, but with escalating wage costs, it is also extortionately expensive. In comparison, our elite harvesting solutions have feed rates that will process 175 pounds of dry weight flower in five hours for a substantially smaller one-off investment. Top this off with an extensive 10-year warranty, and it’s a no-brainer to streamline costs and boost profitability.

3. How do trimmers account for extensive genetic diversity?

The sheer variety of cannabis poses a challenge for automated trimmers, with flower size, shape, density and moisture all impacting movement through the machines and, consequently, the tightness of the trim. To accommodate for the full range of cannabis and hemp genetics, growers need the ability to modify solutions on the fly to adapt to different strains.

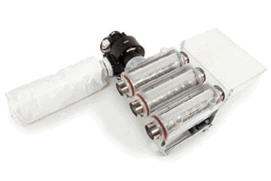

To solve this deep-rooted challenge, we added diverter valves to our trimmers, which enable growers to fine-tune the suction and airflow through the machine. This prevents flowers from being drawn too close, or not close enough, to the cutting blades.

Trim length can be further tweaked by variable speed controls, which can slow the trimmer down for a gentler dry trim, or speed it up for a higher feed rate with heavy resin-coated buds. By connecting trimmers in tandem using the CenturionPro Rail System, cultivators can benefit from multiple diverters and multiple speed controls for enhanced control to refine tightness of the trim on a strain-by-strain basis.

4. What should cultivators look for in harvesting solutions?

The ability to process wet and dry product should be a no-brainer, as it enables growers to be versatile with the agility to adapt to emerging opportunities. The same is true of trim and kief collection systems, which minimize waste and maximize a harvest’s value. Producers in regulated markets also need harvesting solutions developed with industry compliance in mind, with food-grade materials that can easily be sanitized.

The machines built from the best brand-name parts deliver the best results, with superior power and precision. Anodized-aluminum and stainless-steel construction ensure robustness and reliability to withstand industrial use. Manufacturers with a commitment to exceptional build quality can stand by their machines, with industry-leading warranties.

Learn more: cprosolutions.com